Are you striving to meet stringent part specifications while accelerating your time to market? At YJCPolymer, we recognize that achieving world‑class quality and consistency begins at the very start of production. That’s why our digital manufacturing ecosystem seamlessly integrates scientific molding, design‑for‑manufacturability (DFM) analysis, and robust quality assurance protocols—anchored by First Article Inspection (FAI). In this in‑depth guide, we’ll explore how FAI underpins rapid, repeatable part quality, the steps we follow at our facility, and why leading automotive, aerospace, medical, and electronics manufacturers rely on YJCPolymer for “quality and consistency at speed.”

Why Quality Control Matters—and Why FAI Leads the Way

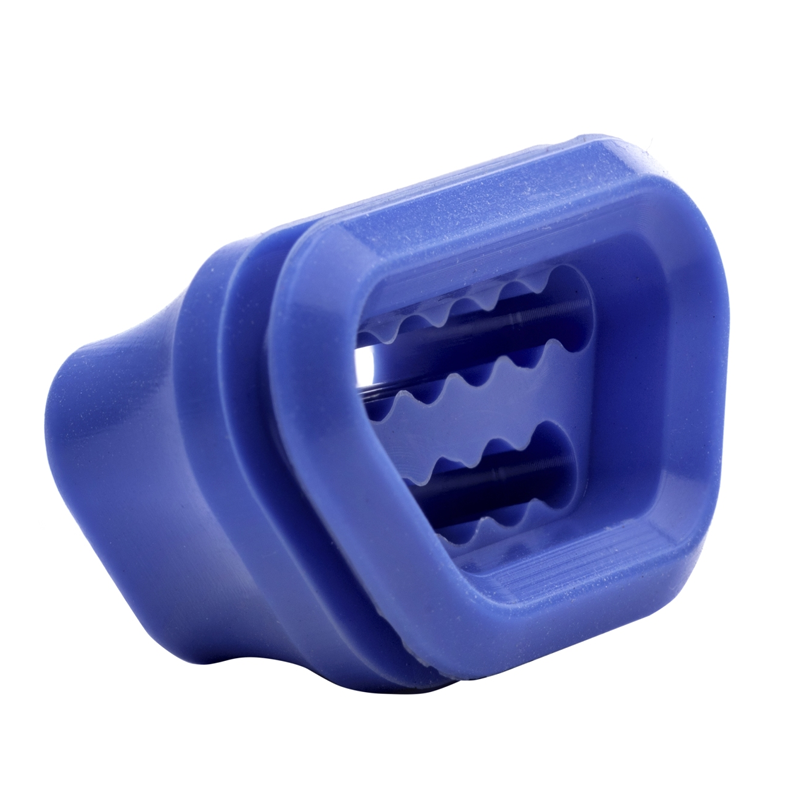

Every industry demands defect‑free components that perform reliably under real‑world conditions. Whether you’re producing safety‑critical aerospace brackets, medical implants, or consumer electronics housings, you need assurance that each batch of parts matches your CAD model and regulatory requirements. Traditional inspection methods—visual checks, random sampling, destructive testing—can catch some errors but often leave gaps in coverage or slow down production.

First Article Inspection (FAI) was developed to bridge that gap. By thoroughly measuring the first parts off the production line against your design’s critical dimensions, FAI provides documented proof that your manufacturing process is dialed in before full‑scale runs begin. At YJCPolymer, we’ve embedded FAI into our quoting and production workflows, ensuring you never commit to molding hundreds or thousands of parts without first validating quality on a handful of samples.

What Is First Article Inspection (FAI)?

Originally conceived during World War II to guarantee uniformity in aerospace and defense components, FAI has evolved into a cornerstone of modern quality management. Defined by industry standards (e.g., AS9102 for aerospace), FAI involves:

- Selection of a small number of parts (often the first 1–10 pieces) at the very start of a run

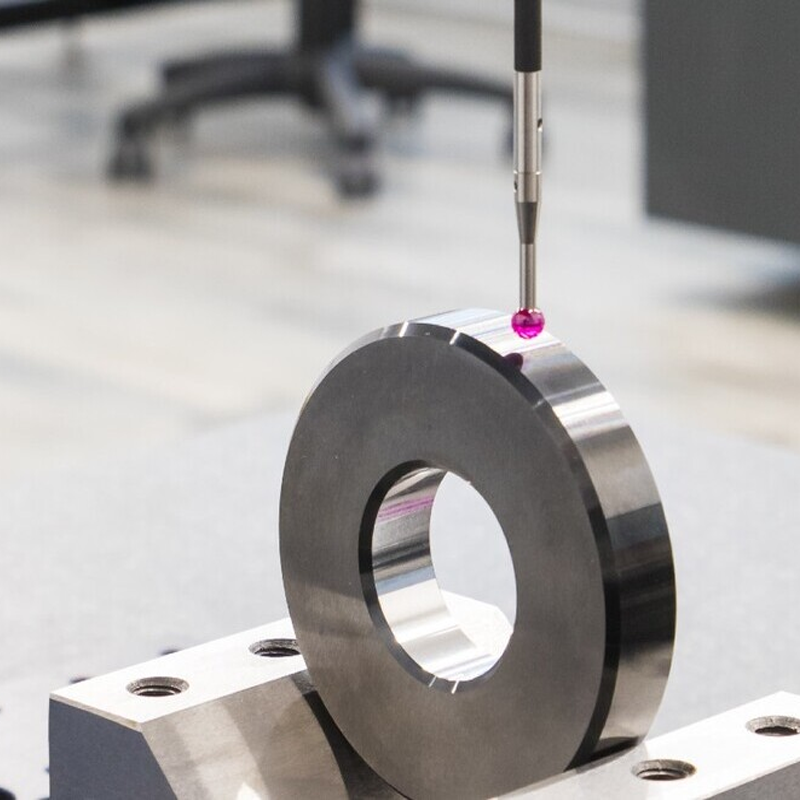

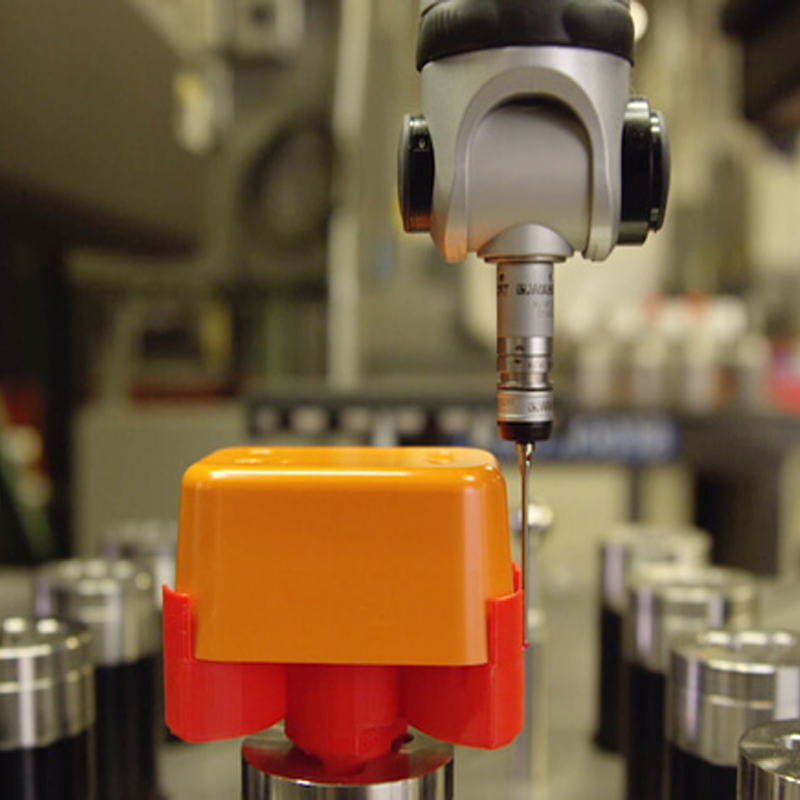

- Measurement of critical dimensions, tolerances, and geometric features using calibrated equipment

- Documentation of results in a formal inspection report, serving as evidence of conformance to customer specifications

By catching deviations early—before hundreds or thousands of parts are produced—FAI helps prevent costly rework, scrap, and production delays.

YJCPolymer’s Partial FAI: Fast, Focused, and Flexible

In our high‑speed, digitally driven environment, we perform a partial FAI designed to balance thoroughness with rapid turnaround:

- Scope: Up to 10 parts evaluated, covering as many as 25 critical dimensions drawn directly from your CAD model (X, Y, Z axes)

- Priority: Features measured are those most critical to form, fit, and function, or those modified since the last production run

- Speed: Our automated quality execution software (MES) and Computer‑Aided Inspection (CAI) tools compress inspection times—delivering FAI reports in hours, not days

Should your project require a full FAI (more parts, more dimensions, additional custom checks), we partner with accredited metrology specialists to scale up the scope without compromising your production schedule.

The FAI Workflow at YJCPolymer

Our FAI process is tightly integrated with tooling setup and production kickoff, ensuring there’s no “inspection bottleneck.” Here’s how we do it:

- Design Review & Inspection Statement of Work (ISOW)

As part of our standard quoting, our engineering team performs a DFM review and drafts an ISOW that defines exactly which features and dimensions will be measured in the FAI. - Fixture and Equipment Preparation

Once the mold is ready, we prepare custom inspection fixtures, jigs, and gauges. Our Coordinate Measuring Machines (CMMs), optical comparators, and handheld probes are all certified to NIST‑traceable standards. - Sample Selection

We pull the first 1–10 parts directly from the machine, ensuring they’ve undergone the same process conditions—temperature, pressure, cycle time—that will prevail throughout production. - Dimensional Measurement

Using automated CMM routines and laser scanning, we capture critical plane‑to‑plane, outside‑diameter, and geometric dimensions. Results are automatically compared against CAD tolerances in our inspection software. - Documentation & Reporting

Inspection data populates a standardized FAI report, complete with dimension callouts, pass/fail status, and any deviation comments. You receive a Digital Inspection Report (DIR) that can be integrated directly into your quality management system. - Review & Sign‑Off

Our applications engineer reviews the findings with you—either approving the process for full production or recommending immediate corrective actions if deviations are detected.

Industries That Depend on FAI—and Depend on YJCPolymer

Automotive: New part introductions, design changes, and regulatory audits all demand FAI to validate each critical feature before running high volumes of parts.

Aerospace & Defense: AS9102‑compliant FAIs are mandatory for any new components or assemblies, ensuring full traceability and adherence to the most rigorous safety standards.

Medical Devices: FDA‑regulated implants and surgical instruments require documented evidence of dimensional accuracy—FAI provides the audit trail needed for regulatory submissions.

Consumer Electronics: Fast‑moving product cycles mean you need confidence that your snap‑fit features, lens pockets, and thermal interface cavities meet specs before mass production.

No matter your sector, our flexible FAI offering—and our willingness to scale the scope—allows you to maintain strict quality governance without sacrificing speed.

The Tangible Benefits of Implementing FAI Early

- Uncompromised Speed:

By automating inspection routines and integrating FAI into our MES platform, YJCPolymer delivers FAI results in hours, not days—keeping tight lead times intact. - Consistent Part-to-Part Quality:

Early verification of critical dimensions guarantees that each subsequent part meets the same high standard, batch after batch. - Regulatory & Compliance Evidence:

A formal FAI report provides the documented proof necessary for ISO, ISO/TS, AS, FDA, or customer‑specific audits. - Early Defect Detection:

Should a design or process issue arise, FAI flags it before large volumes are produced—minimizing scrap and avoiding expensive retooling. - Cost Savings & Waste Reduction:

Catching problems at the start of a run slashes the costs associated with defective parts, secondary inspections, and production downtime.

Overcoming Common FAI Challenges with Digital Manufacturing

Even the best‑planned FAI process can face hurdles such as:

- Complex part geometries that require elaborate fixture design

- Extensive documentation burdens, especially when regulations tighten

- Production timelines that leave little room for extended inspection cycles

- Design changes in mid‑run, necessitating quick revalidation

At YJCPolymer, our proprietary Manufacturing Execution Software (MES) and integrated digital inspection tools mitigate these challenges:

- Automatic ISOW updates when your CAD model changes

- Configurable inspection plans that adapt to part complexity

- Real‑time monitoring and alerts for out‑of‑tolerance conditions

- Seamless data export to your ERP, PLM, or QMS for instant traceability

This digital backbone allows us to maintain “quality and consistency at speed”, even when your project demands change on the fly.

Conclusion:

Ready to elevate your part quality from the very first article? By embedding FAI into our digital manufacturing workflow, YJCPolymer delivers the data‑driven insights you need to launch production with absolute confidence—no matter how tight your schedule or how stringent your tolerances.

Let’s talk about your next project. Reach out to our injection molding and quality assurance experts to determine the optimal FAI scope for your parts. Together, we’ll tailor a fast, efficient inspection strategy that aligns with your compliance requirements and accelerates your time to market.

Contact YJCPolymer today—because with FAI at the heart of our process, your first article truly sets the standard for every article that follows.