Proudly Providing

Specialized Solution

As a manufacturer, We have also garnered expertise in tooling manufacturing, ensuring the highest standards of quality and precision.

we have a strong focus on providing customized solutions in the field of silicone, plastic, metal stamping and zinc-copper alloy manufacturing.

YJC Polymer is dedicated to delivering outstanding specialized customer care to our valued customers.

Silicone Rubber & Metal Parts Manufacturer

Our Manufacturing Capabilities

YJC Polymer Co,. LTD is a leading and comprehensive supplier specializing in the production of high-quality silicone rubber, plastic, and metal products. With a seamless production chain encompassing R&D, rapid prototyping, CNC machining, tooling design and manufacturing, pilot and mass production, assembly, full inspection, packing, and delivery, we offer a one-stop solution to meet all your manufacturing needs.

Plastic Injection

Plastic Injection molding is the most cost-effective method for mass-producing plastic components. We provides on-demand prototyping and production molding solutions.

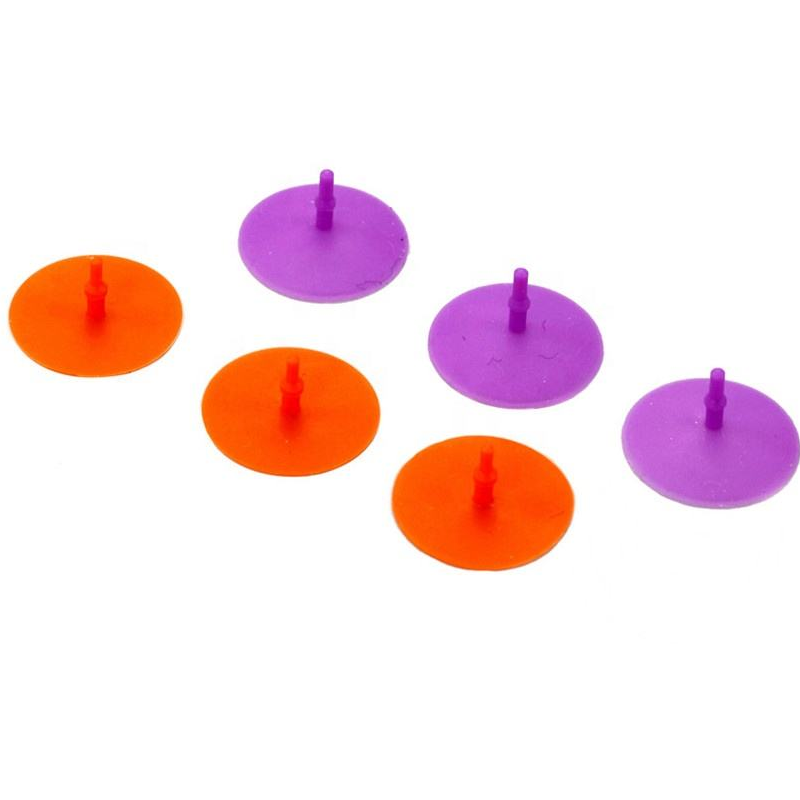

Silicone Injection

Our expertise includes LSR and plastic injection molding ,overmolding, and multi shot molding. From functional prototypes to large-volume production.

Silicone Compression

We specialize in silicone compression molding and rubber compression molding,for medical and healthcare industry.

Silicone Extrusion

YJC Polymer excels in Precision Extrusion Molding for Silicone and Plastic, serving a broad spectrum of industries. we supply custom-extruded elastomeric products for a variety of applications.

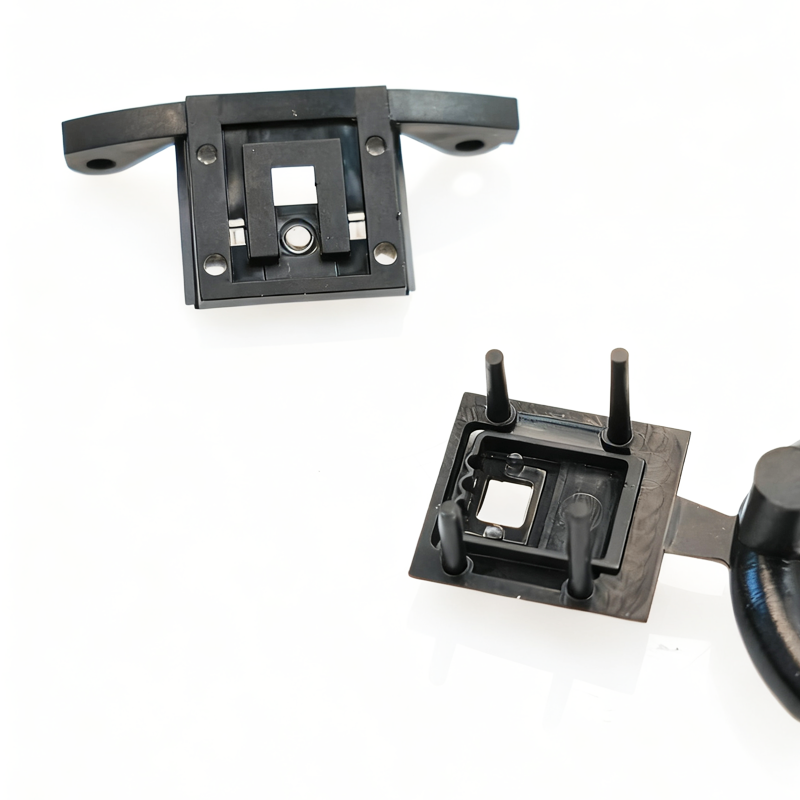

Mould Making

Our decades of tooling manufacturing design expertise extend across various specialized areas, including plastic & LSR injection molding, over-molding, silicone compression molding, and silicone and plastic extrusion.

3D Printing

We specialize in Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Multi-Jet Fusion (MJF) technologies.

CNC Maching

We offer precise milling and turning services, complemented by post-processing options such as anodizing and painting.

Die Stamping

Experience our exceptional manufacturing capabilities in metal stamping. With precision metal stamping dies and top-tier fabrication services, we deliver superior results.

Xiamen YJC Polymer Limited

YJC Polymer Co,. LTD. has the world's top mold and production molding equipment, with mature LSR(liquid silicone rubber) and plastic parts of the technical team, we can provide customers with excellent product quality.

"永精诚" in "厦门永精诚橡塑科技有限公司" can be translated into English as "Perpetual Excellence and Sincerity." In this phrase, "永" signifies perpetuity and longevity, representing qualities of perseverance and enduring commitment. "精" conveys precision and continuous improvement, reflecting the pursuit of excellence and perfection. "诚" means honesty and sincerity, embodying genuineness and integrity.

Therefore, "永精诚" encapsulates the notion of possessing enduring integrity and sincerity while striving for excellence. This phrase emphasizes moral and character values, expressing reverence for authenticity, honesty, and noble qualities.

How To Work With Us

In an era of clear specialization and industrial standardization, we continuously enhance our competitiveness in the silicone field. We not only address specific needs within your industry but also offer a one-stop solution for silicone-based products. Below is our standard collaboration process. Feel free to reach out if you have any questions.

Non-disclosure Agreement (NDA)

We ensure your sensitive information stays secure by signing an NDA for confidentiality.

Drawing and Requirement

Please provide 2D/3D files in STEP or X_T format along with your concept and requirements.

Providing Quotation

Our quoting process delivers accurate, cost-effective pricing tailored to customer needs. 4.DFM and tooling 3D approval.

DFM and Tooling 3D Approval

Our team conduct DFM analysis to ensure feasibility, then design tooling 3D for approval.

Tooling Manufacturing

Our experienced tooling engineers develop precise solutions that align with your product design and manufacturing needs, using the top-class CNC ,EDM and other precision machines,

Samples and PPAP Approval

After obtaining clients' approval, we supply T0 and P0 samples and comprehensive PPAP documents, demonstrating compliance with industry standards and outlining the production process.

Production and Inspection

During pilot and mass production, we leverage expertise, advanced facilities, and quality control measures to efficiently produce high-quality products. Then a final and full inspection ensures the high quality.

Packing and Delivery

We consider product size, shape, fragility, branding, and marketing objectives when developing packaging solutions. Additionally, transportation options (sea, air, land) are assessed based on delivery speed, cost, and destination.

Silicone & Rubber Main Market & ProfitsVIEW MORE >>