Overview

This precision Liquid Silicone Rubber (LSR) Injection Molded Cross Slit Ketchup Valve is engineered for reliable, drip-free dispensing of viscous condiments and sauces. Manufactured using high-purity, food-grade LSR, it offers superior resealing, chemical resistance, and long-term flexibility. Our factory provides full OEM services for design, flow rate, color, and branding to meet your specific packaging application.

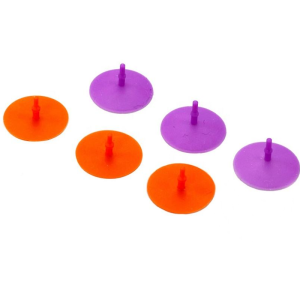

![]()

Basic Information

| Attribute | Details |

|---|---|

| Material | Food Grade Liquid Silicone Rubber (LSR) |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Color | Translucent, White, or Custom |

| Packing | OPP bag, PVC box, or customized |

| Logo | Customized |

| Temperature | –50 to +200 °C |

| OEM | Available |

| MOQ | Small orders accepted |

| Sample | Can be provided |

| Technology | LSR Injection Molding |

Benefits of Our Products

-

Precise Flow Control: The cross-slit design ensures consistent, clean dispensing and reliable resealing.

-

Durable & Resilient: High-quality LSR maintains flexibility and performance over thousands of cycles.

-

Hygienic & Easy-Clean: Non-porous surface resists residue buildup and is simple to sanitize.

-

Tailored Design: Fully customizable dimensions, slit configuration, and mounting features.

Quality Assurance

Our quality assurance for LSR Ketchup Valves is built on certified processes and precise validation. We operate under ISO 9001 and comply with FDA food-contact standards. Each production run undergoes rigorous checks using specialized equipment: flow rate testers to verify consistent dispensing, cycle-testing machines to validate slit durability and resealing over thousands of actuations, dimensional CMM for accuracy, and leak-proof pressure tests to ensure perfect closure. This ensures every valve delivers reliable, leak-free performance.

Why Partner with Us for Your Manufacturing Needs?

-

Expertise in Precision LSR Molding: With deep specialization in Liquid Silicone Rubber injection molding, we deliver valves with exceptional consistency, flash-free trimming, and reliable mechanical performance.

-

Rapid Prototyping & Customization: We excel at translating your dispensing requirements into a functional design, offering fast prototyping for fit, form, and flow testing before full-scale production.

-

Stringent, Process-Led Quality Control: Our focus extends beyond final inspection to include precise process control over material mixing, injection parameters, and post-curing, ensuring batch-to-batch uniformity.

-

Integrated, Reliable Supply: As your direct factory partner, we manage the complete process from mold making to finished valves, ensuring supply chain transparency, efficiency, and on-time delivery.

Factory Show

Our dedicated LSR molding facility is equipped with advanced multi-component injection machines and automated systems designed for high-precision, high-volume valve production. We utilize cleanroom environments for critical stages, automated vision inspection for quality verification, and precision tooling maintained by CNC and EDM equipment. The entire process—from material preparation and injection to curing and deflashing—is controlled and monitored, supported by ISO 9001 certified quality management, to ensure the production of hygienic, reliable, and consistent dispensing valves.