Presenting our meticulously crafted assembly parts, each designed for optimal performance:

M3 Screw: Crafted from 1008 steel and zinc-plated, this screw undergoes a rigorous 36-hour salt spray test, ensuring corrosion resistance. It meets the stringent grade 4.8 strength requirement.

Square Washer: Made from DC04 steel, zinc-plated, and shaped through precise mold stamping, this washer endures a 36-hour salt spray test. When assembled with the M3 screw, it undergoes a 1.2Nm torque test and a gauge check, guaranteeing secure connections.

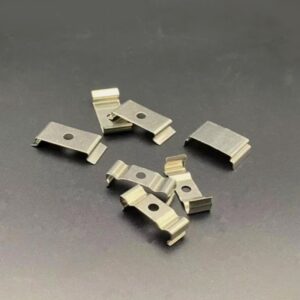

Stamped Clip: Fabricated from H62 brass with a nickel base and tin top layer, this clip meets high standards after a thorough inspection. Assembled with the square washer and M3 screw, it maintains a parallelism of 0.1. The screw’s locking force ranges between 0.2-0.5Nm, ensuring stability.

After assembly, stringent Quality Control (QC) tests are conducted to ensure the assembled parts meet our high-quality standards. Trust in our precision-engineered components for your industrial needs.

Specification

Materials: steel, stainless steel, brass, copper, bronze, aluminum, titanium, etc

Size: as customers’ request

Color: according to customers’ needs

Tolerance: 0.01mm

Surface Treatment: brushing, polishing, electrophoresis, anodized, powder coating, plating, silk screen, laser engraving, etc

Production Process: cold frogging, machining and CNC, stamping, welding, bending

Certifications: ISO 9001

Test: 48H salt-spray testing, 2D testing, plainness testing

Quality Control: 100% inspection before shipment

OEM/ODM: available

Samples: free available

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packing: plastic bag, carton and pallet or according to customer’s needs

Delivery Term: by sea/express

Application: machinery, chemical industry, environmental, furniture, industrial, construction, electronic, appliance, automotive

Surface Treatment

- Brushing: Achieving a uniform brushed texture, enhancing visual appeal and texture.

- Polishing: Employing precision techniques for a smooth, reflective surface, ensuring a refined look.

- Electrophoresis: Providing a corrosion-resistant, even coat through an electrochemical process, ensuring long-lasting protection.

- Anodizing: Creating a robust oxide layer, enhancing corrosion resistance and offering vibrant color options.

- Powder Coating: Applying a durable powder layer, providing excellent protection and a variety of color choices.

- Plating: Employing various metals like zinc, nickel, or chrome, enhancing both appearance and corrosion resistance.

- Silk Screen: Applying intricate designs with precision, ensuring clear, detailed markings.

- Laser Engraving: Utilizing laser technology for precise, permanent markings, enhancing brand identity and traceability.

Our commitment to diverse and high-quality Surface Treatments guarantees that our Custom Assembly Metal Components not only meet but exceed industry standards, both in functionality and visual appeal.