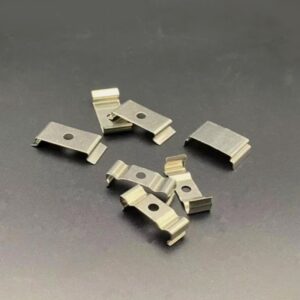

With 100% inspection pre-shipment and options for OEM/ODM customization, our Battery Metal Clips provide efficient and dependable power connections for various industrial needs.

Battery Metal Clips for Efficient Power Connection are used in a variety of applications. Crafted from steel, stainless steel, brass, copper, aluminum, and titanium, these clips ensure enduring performance. Customizable in size and color with a tolerance of 0.01mm, they feature embossed logos or prints for a personalized touch. Undergoing meticulous surface treatments including brushing, polishing, anodizing, and plating, these clips guarantee superior corrosion resistance. Manufactured through processes like cold forging and stamping, they meet rigorous quality standards, including 48H salt-spray testing. Certified with ISO 9001, these clips find applications in machinery, electronics, automotive, and more.

Specification

Specification

Materials: steel, stainless steel, brass, copper, bronze, aluminum, titanium, etc

Size: as customers’ request

Color: according to customers’ needs

Tolerance: 0.01mm

Logo: embossed, printing, silk screening, etc

Surface Treatment: brushing, polishing, electrophoresis, anodized, powder coating, plating, silk screen, laser engraving, etc

Production Process: cold frogging, machining and CNC, stamping, welding, bending

Certifications: ISO 9001

Test: 48H salt-spray testing, 2D testing, plainness testing

Quality Control: 100% inspection before shipment

Samples: free available

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packing: plastic bag, carton and pallet or according to customer’s needs

Delivery Term: by sea/express

Application: machinery, chemical industry, environmental, furniture, industrial, construction, electronic, appliance, automotive

Our Advantages

- State-of-the-Art Facilities: Our facilities are well-equipped with cutting-edge technology and modern machinery, enabling us to meet diverse production requirements efficiently and effectively.

- High-Quality and Competitive Pricing: We offer high-quality products at competitive prices, striking the perfect balance between excellence and affordability, making us a preferred choice in the market.

- Stringent Quality Control: Our strict quality control system guarantees the consistency and reliability of our products. Every item undergoes rigorous testing to meet industry standards

- Professional Workforce: Our team consists of skilled and dedicated professionals who are experts in their respective fields, ensuring the highest quality output and customer satisfaction.

- OEM Capabilities: We are highly adaptable to OEM projects, tailoring our services to meet specific client needs, thereby enhancing the overall product customization experience.

- Customized Services: We specialize in providing tailored solutions. Our commitment to customization ensures that every client’s unique requirements are met, enhancing the value of our offerings.