Description:

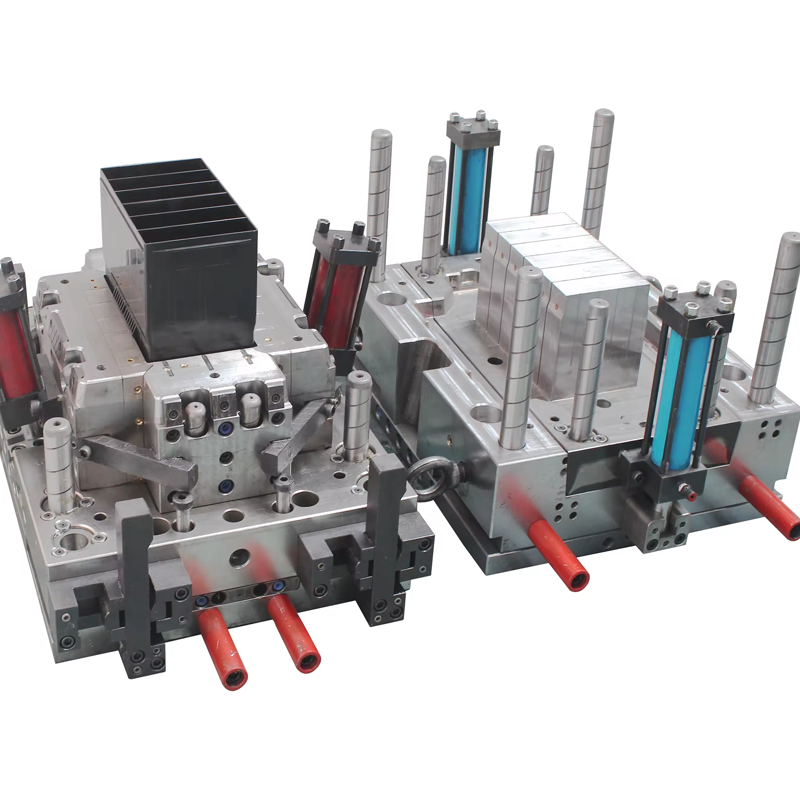

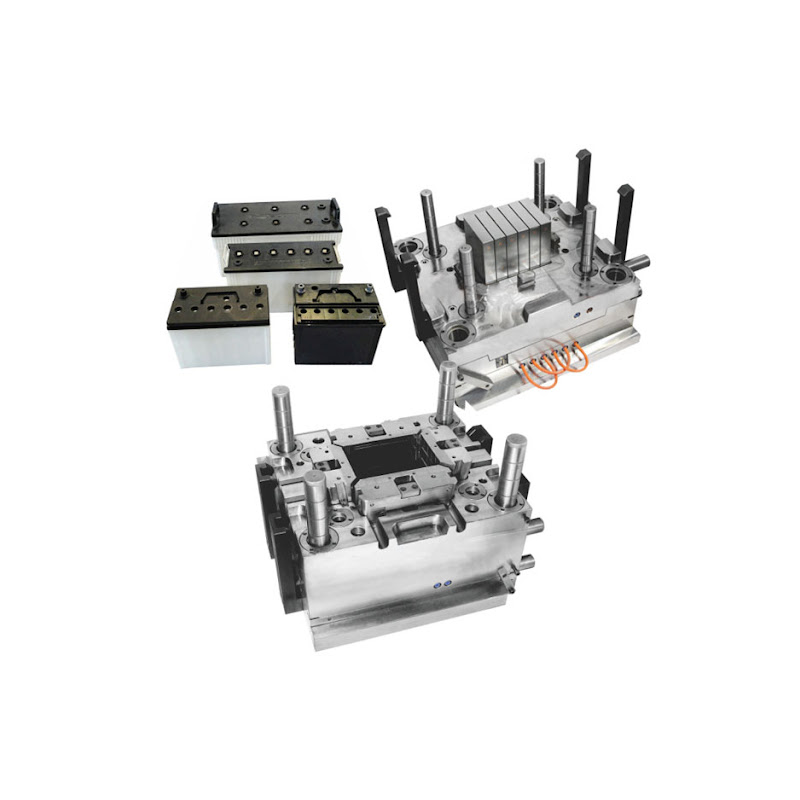

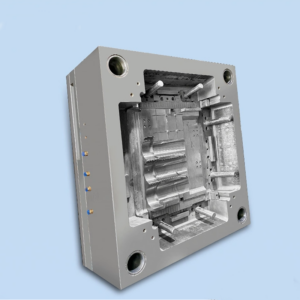

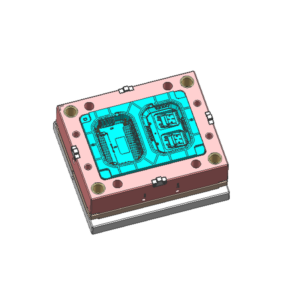

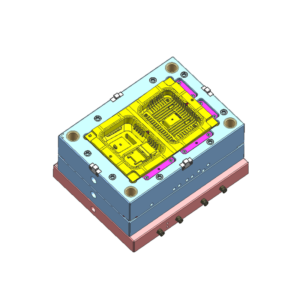

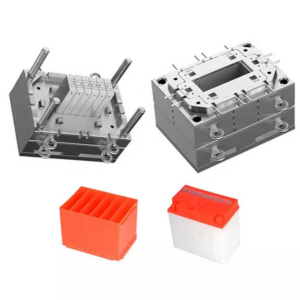

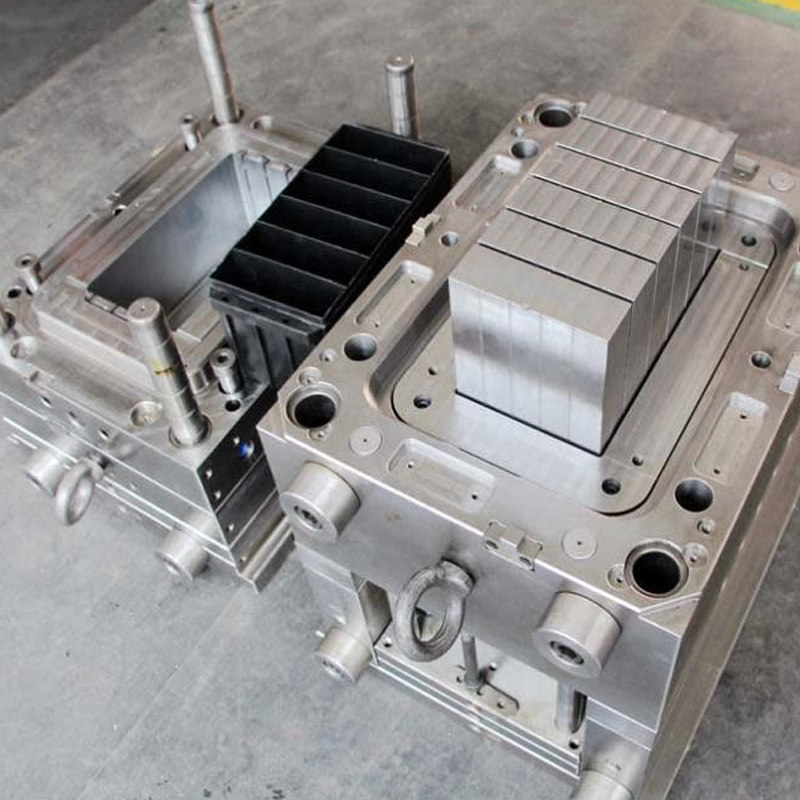

The Custom Plastic Battery Box Case Tooling Mould for the Automotive Industry is a high-precision solution engineered to produce robust, high-performance battery box cases for vehicles. Made from top-grade materials such as steel or aluminum, these molds incorporate advanced injection molding techniques, ensuring superior accuracy and efficiency in production. As experienced manufacturers, we offer end-to-end one-stop services, delivering customized solutions tailored to your precise requirements while ensuring cost-effective and dependable outcomes. Our molds are manufactured in strict compliance with ISO 9001 and IATF 16949 quality standards, ensuring exceptional performance and long-lasting durability for all automotive applications.

Basic Information:

Place of Origin: Xiamen, China

Brand Name: OEM

Product Material: Steel

Runner System: Hot/Cold Runner

Mould Design Software: UG, PROE, SOLIDWORKS, CAD, etc.

Sample: Available

Certification: ISO9001, IATF16949

Packaging: Custom

MOQ: According to your requirement

Lead Time: 25-30 days

Advantages of Our Tooling:

- Superior Dimensional Accuracy and Stability

- Optimized Cycle Times through Advanced Conformal Cooling Techniques

- Tailored Tooling Engineering for Specific Material Requirements

- Scalable Production with ISO 9001 and IATF 16949 Certification

Quality Assurance:

Our quality assurance for Customized Plastic Battery Box Case Tooling Molds for the Auto Part Industry is grounded in rigorous testing and precise manufacturing processes. We are certified to ISO 9001 and IATF 16949 standards, ensuring compliance with the highest industry quality management systems. Our comprehensive inspection procedures include first-article validation, in-process monitoring, and final product testing. We utilize advanced testing equipment, including coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers, to guarantee the molds’ dimensional accuracy, material integrity, and optimal performance. Additionally, our automated vision systems and material testing further ensure that each mold meets the demanding standards required for automotive applications.

Our Strengths:

- Precision Machining

- Quality Guarantee

- Professional Advanced Equipment

- One-stop Service

- Rapid Prototyping

- Tolerances Down to +0.03mm

- DFM Feedback

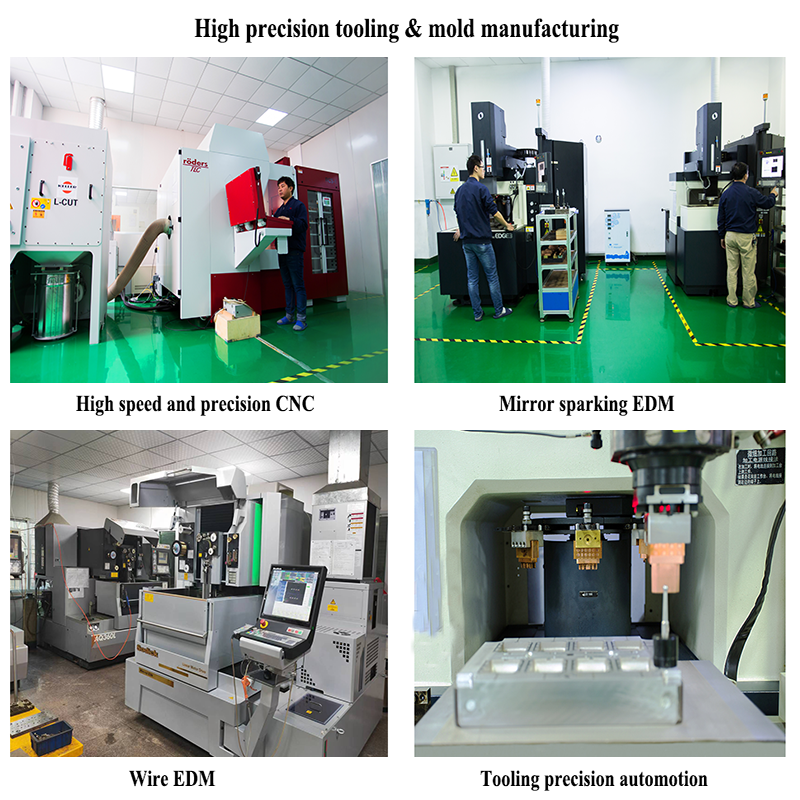

Factory Show:

Our advanced manufacturing facility is equipped with cutting-edge technologies, including CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC), allowing for superior precision in mold production. To further enhance our capabilities, we operate 15 rubber compression molding presses and 2 LSR injection molding machines, optimizing production efficiency while ensuring consistent performance across large volumes. We utilize state-of-the-art inspection tools such as 3D projectors, sealing testers, durometers, and elasticity gauges, all managed by our certified quality control team to meet the highest industry standards. Fully compliant with ISO 9001 and IATF 16949 certifications, we provide reliable, high-performance manufacturing solutions. Additionally, our automated systems, including AutoDryers, high-speed doming machines, and precision die-cutting systems, improve both productivity and precision, ensuring top-tier product quality and uniformity throughout every phase of production.