Overview

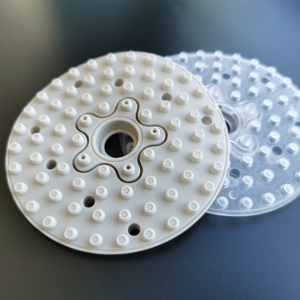

Our silicone compression molding shower head nozzle gaskets provide a reliable, leak-proof seal for lasting performance. Made from durable, mold-resistant silicone, they withstand water pressure and temperature changes. We offer full OEM customization of size, profile, and hardness for a perfect fit in your shower assembly.

![]()

Characteristics

| Specification | Details |

|---|---|

| Product Name | Silicone Shower Head Nozzle Gasket / Seal |

| Material | High-Performance Silicone Rubber (HCR) |

| Shape | Custom O-Ring, Square, Washer, Complex Profile |

| Color | Transparent, White, Black, Custom |

| Hardness (Shore A) | 40 – 70 (Standard 50±5) |

| Primary Function | Watertight Seal, Vibration Dampening |

| Temperature Range | -40°C to +200°C |

| Certifications | FDA (Material), ROHS, REACH, NSF/ANSI 61 (Optional) |

| MOQ | Small Order Accepted |

| Logo/Branding | Embossed |

| Key Feature | Excellent Compression Set Resistance, Anti-Mildew |

| Dimensions | Fully Customizable (Provide Drawing) |

| Packing | PE Bag, Box, Reel |

| Tolerances | ±0.15mm (Standard) |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 3 Million+ PCS Per Month |

OEM Process for Silicone Gaskets

-

Drawing & Specification Submission: Provide detailed 2D drawings (PDF, DWG) or 3D files (STEP, IGS) with all critical dimensions and material requirements.

-

Technical Review & Quotation: Our engineers perform a DFM analysis and provide a formal quotation with material recommendations.

-

Prototype Sampling: Precision-cut or molded samples are produced for fit, form, and function verification with your shower head.

-

Approval & Order Confirmation: Upon sample approval, confirm the order. A proforma invoice is issued for the production mold/tooling.

-

Production Tooling & T1 Approval: Hard production molds for compression molding are manufactured. First article samples (T1) are submitted for final approval.

-

Mass Production & Quality Control: Full-scale compression molding begins. Statistical process control (SPC) ensures dimensional consistency. Batch sampling for key checks.

-

Delivery: Finished gaskets are packaged as specified and shipped.

Why Choose Us

-

Expertise in Precision Compression Molding: We specialize in high-volume compression molding of silicone seals, ensuring cost-effective production with consistent quality and precise tolerances for plumbing applications.

-

Full Customization & Engineering Support: We offer complete collaboration to develop the optimal gasket profile, size, and material compound (including anti-mold additives) for your specific water pressure and environmental conditions.

-

Vertical Manufacturing for Reliable Supply: Our in-house control over mold making, compounding, and production guarantees tight tolerances, faster lead times, and a secure supply chain for your critical components.

-

Proven Partner for Plumbing & Fixture Manufacturers: With extensive experience supplying seals to the bathroom fittings industry, we understand the requirements for durability and performance, making us a reliable OEM partner.

Factory Show

Our facility is equipped with multiple high-tonnage compression molding presses dedicated to silicone rubber parts. We operate an in-house mixing room to prepare custom silicone compounds. Our tool room utilizes CNC machining and grinding to craft durable, precision molds. Quality assurance is performed with optical comparators for dimensional checks and durometers for hardness verification. Operating under a structured quality management system, we ensure every gasket meets the specifications required for reliable, long-term sealing in shower and faucet applications.