Show Filters

Read More

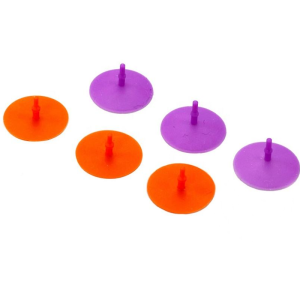

umbrella check valve

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Food-grade Silicone (VMQ) or Liquid Silicone Rubber (LSR) — FDA / LFGB options |

| Manufacturing Method | Automated LSR injection molding (two-component metering, hot-runner) or compression molding for select geometries |

| Typical Hardness | Shore A 10–40 (tuned to product viscosity & response) |

| Size | Fully customizable — ID/OD, valve height, skirt/lip geometry per drawing |

| Temperature Range | –40 °C to +200 °C (compound dependent) |

| Tensile / Elongation | Tensile ≥ 7 MPa; Elongation ≥ 300% (compound dependent) |

| Chemical Resistance | Resistant to acids, oils, salts, and common cleaning agents used in food service |

| Typical Performance | Bench-verified drip control and back-pressure sealing per customer specification (typical functional test to 50 kPa back-pressure) |

| Cycle Life | >100k actuations typical; higher cycle life available with optimized compound & design |

| Packaging | OPP bag, vacuum tray, blister pack, taped reels, or custom retail packaging |

| Marking / ID | Mold embossing, laser marking or pad print where applicable |

| OEM Services | DFM, mold design, rapid prototyping, pilot runs, overmolding, assembly, testing & packaging |

| MOQ | Small pilot orders accepted; scalable to mass production |

| Samples | Prototypes and production samples available upon request |

| Typical Applications | Squeeze bottles, pump nozzles, tabletop dispensers, single-serve applicators, beverage nozzles |

Showing the single result