What is Overmolding?

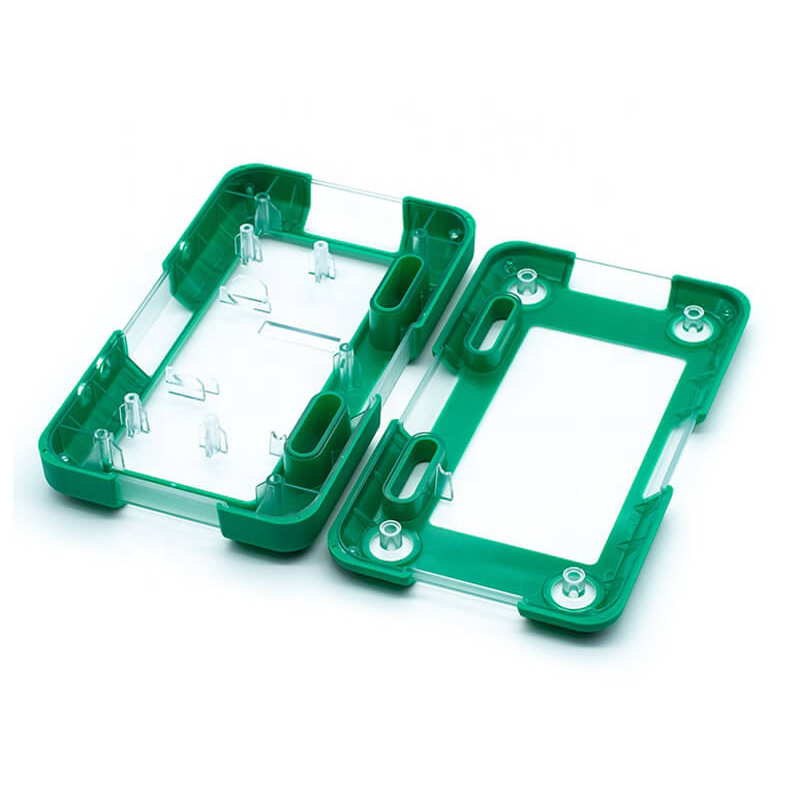

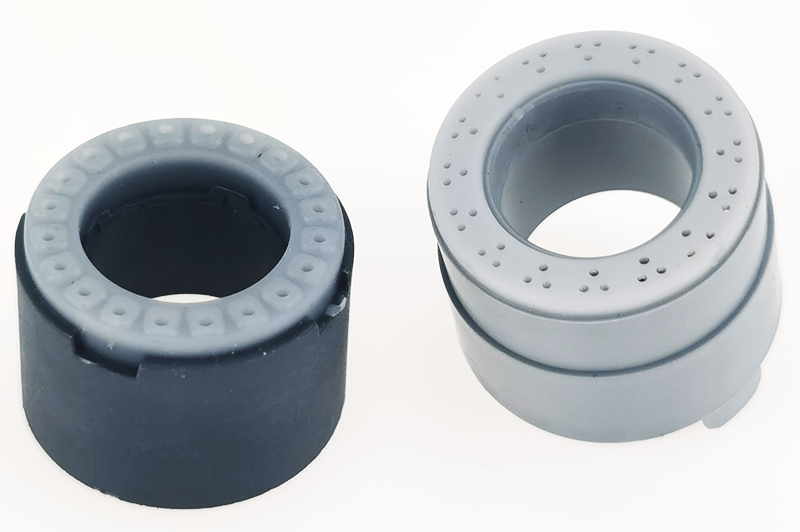

Overmolding is a two-shot plastic injection molding process that creates a single part by combining two different but complimentary thermoplastic materials.

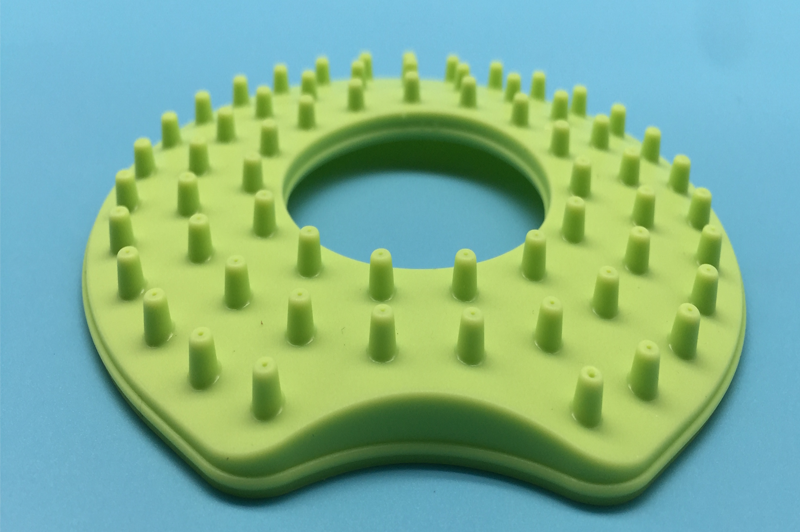

The first shot, the substrate, is usually composed of more rigid plastic and is designed to accept the second shot, second material, usually a softer and more flexible material such as rubber or thermoplastic elastomer (TPE), called the overmold. The overmold is typically composed of a softer, more flexible plastic-like rubber.

By mechanically or chemically bonding two plastic materials, creating a seamless and cohesive final product.

LSR Overmolding Service

Yjc Polymer stands out as a premier LSR overmolding manufacturer, with over 20 years of experience in delivering cost-effective solutions for precision Liquid Silicone Rubber (LSR) and plastic or metal overmolding components and assemblies.

Why Choose Us?

Precise Control

We employ high-precision injection molding machines and advanced control systems to monitor and adjust key parameters like temperature, pressure, and speed in real-time, ensuring stable and consistent LSR injection. This precise control guarantees consistent product dimensions and quality, meeting the stringent demands for high-quality LSR products from our customers. Whether it's small-batch or large-scale production, we maintain a high level of accuracy throughout the manufacturing process.

Multi-material Molding

Yjc Polymer stands out in multi-material molding, incorporating two-shot, insert, and overmolding techniques. This advantage allows us to combine different LSR materials with other materials in a single mold, enabling diverse and complex product designs. We provide flexibility to meet various performance requirements, customize colors, simplify manufacturing processes, and enhance product quality, positioning us as a leading provider in the LSR injection molding industry.

Extensive Production Capacity

Our advanced manufacturing facility features over 10 sets of LSR injection machines ranging from 60 to 160 tons, providing extensive production capacity and flexibility. We leverage advanced control technology to deliver high-quality LSR products promptly and offer customized solutions to meet specific customer requirements.

Comprehensive Overmolding Products Solutions

Our comprehensive services encompass the entire Overmolding molding process, offering value-added solutions from design and prototyping to packaging and delivery. Count on us to provide tailored services and outstanding support at every stage of your project.

Trusted Manufacturer Of LSR Overmolding Products

Yjc Polymer silicone parts is a trusted partner for major OEMs worldwide, specializing in the overmolding process to deliver top-notch parts. With two decades of experience in liquid silicone rubber (LSR) components, advanced production capabilities, and exceptional quality and metrology systems, we are well-equipped to meet your project needs.

Materials Used For Overmolding

We offer a wide range of materials for overmolding projects, depending on the geometry, complexity, and requirements of your project. These materials can be divided into three different categories, including:

Rigid Plastics: ABS, Polypropylene, Polycarbonate, Acrylic, Nylon, POM, PTFE, PBT/PBT-PC, PEEK, HDPE, PVC, PPS,PI, PAI, UPE/UHMW, PVDF, ULTEM (PEI)

Flexible Plastics: PS, PET, EVA Foam, EPS Foam, PU Foam

Rubber Plastics: TPU, Silicon Rubber

Tolerances

| Mold Type | Dimensional Tolerance |

| Substrate Molds | ± 0.02 mm, with an included resin tolerance that can be greater but no less than 0.02 mm |

| Thermoplastic Overmolds | Tolerances consistent with substrate molds |

| LSR Overmolds | ± 0.02 mm |

Finishing

Painting

Painting the surface with standard colors or Pantone matching, including Primer and topcoat. Masking available; EMI (copper) paint.

Mold Texturing

Creating textures on the molds so that it shows on the final product. This finishing option includes matte, swirls, patterns, and lines.

Threaded Inserts

We can install the most commonly used and popular standard inserts in UNF and metric sizes.

Laser Engraving

Engrave part numbers, designs, logos, or any other specified printing onto your parts.

SPI Finishes

Range of SPI finishes from Grade 3 diamond / high polish to 320 stone low polish.

Pad Printing

Application of an ink-based design to the surface.

Standard Finish

Interior, non-cosmetic finish according to the geometry of the mold.

As Molded

As the name suggests, the mold will remain ‘as it is’ – without any secondary texturing or polishing.

Applications of Overmolding

● Soft-grip handles for hand tools

● Toothbrush grips

● Medical device handles and grips

● Automotive interior components like steering wheels and shift knobs

● Electrical connectors and cables with strain relief

● Sealed and waterproof electronics

● Multi-colored or multi-material parts for consumer goods

● Industrial equipment with ergonomic grips

● Outdoor and sports equipment handles

● Wearable technology for comfortable, durable wearables.