Are you exploring ways to reduce vehicle mass without sacrificing performance, safety, or aesthetic appeal? At YJCPolymer, we partner with OEMs and tier‑one suppliers to develop advanced polymer solutions that deliver metal‑level strength at a fraction of the weight. In this blog, we’ll examine how lightweight engineering plastics are reshaping automotive body structures and interior components—and why high‑temperature nylons and polyphthalamide (PPA) are fast becoming preferred substitutes for traditional metal parts.

1. The Drive for Lightweighting in Automotive Design

Fuel efficiency standards, emissions regulations, and the transition to electrified powertrains have placed intense pressure on automakers to trim weight. Every 10% reduction in vehicle mass can yield a 6–8% improvement in fuel economy, or extend electric‑vehicle range by up to 10%. Historically, aluminum and high‑strength steels have been the go‑to materials for lightweighting. Today, advanced polymers—when appropriately selected and engineered—offer comparable mechanical performance with even greater design flexibility and cost advantages.

2. Engineering Plastics for Body Structure Components

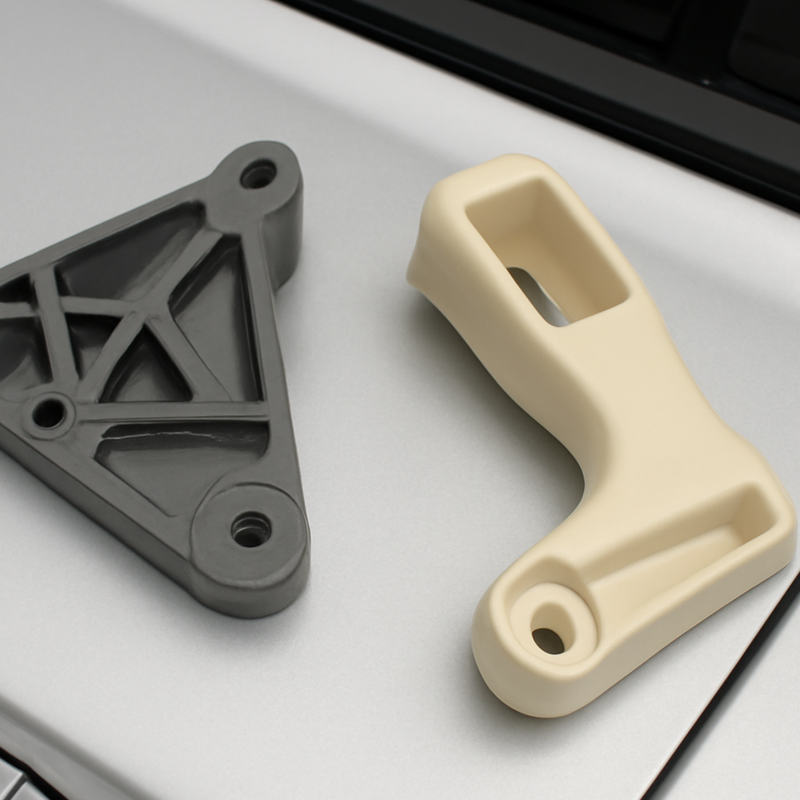

2.1 Reinforced Polyamides in Structural Brackets and Mounts

Glass‑fiber‑reinforced nylons (PA6 GF30, PA66 GF35) deliver tensile strengths exceeding 100 MPa and heat deflection temperatures above 140 °C, making them ideal for engine bay brackets, suspension mounts, and structural clips. Compared to stamped steel, these composites can reduce part weight by 30–50% while resisting corrosion and vibration fatigue.

2.2 Polycarbonate‑ABS Blends for Impact‑Resistant Subframes

PC‑ABS blends combine the toughness of acrylonitrile butadiene styrene with the transparency and heat resistance of polycarbonate. They are used in subframe components, radiator end tanks, and headlamp housings. The result: parts that survive rock chips, thermal cycling, and chemical exposure—without the tooling costs associated with aluminum die‑castings.

2.3 Thermoplastic Composites in Crash‑Energy Management

Carbon‑fiber‑reinforced thermoplastics (CFRTP) and long‑glass‑fiber composites can replace steel reinforcement beams and impact absorbers. Their sandwich constructions—thermoplastic skins over a honeycomb core—absorb crash energy efficiently and can be recycled more easily than thermoset composites.

3. Elevating Interior Components with Advanced Polymers

3.1 Lightweight Door Panels and Consoles

Engineering plastics such as polypropylene (PP) reinforced with talc or glass fibers deliver a smooth surface finish, excellent dimensional stability, and lower density than ABS or PC‑ABS. Hollow‑blow molding and gas‑assist injection techniques further reduce weight and material usage in door trims and center consoles.

3.2 Decorative Trim and Tactile Interfaces

Thermoplastic elastomers (TPE) overmolded onto ABS substrates provide soft‑touch, vinyl‑like surfaces for armrests and dashboards. Co‑injection molding with PC‑TPU blends enables two‑tone color effects and integrated LED light guides—eliminating post‑assembly adhesives and trims.

3.3 Acoustic and Thermal Insulation

Expanded polypropylene (EPP) and thermoplastic polyurethane (TPU) foams are increasingly used in headliners, pillar trims, and firewall pads. These materials combine low weight with superior sound absorption (NRC ≥ 0.6) and heat resistance, enhancing cabin comfort and NVH (noise, vibration, harshness) performance.

4. High‑Temperature Nylons and PPA: The New Metal Challengers

As under‑the‑hood temperatures climb—especially in hybrid and EV powertrains—standard plastics can’t withstand prolonged exposure above 150 °C. Enter high‑temperature nylons (PA46, PA9T) and PPA:

4.1 Polyphthalamide (PPA) for Hot‑Zone Components

PPA grades like PPA 6T/66 maintain tensile strengths of 120 MPa at 150 °C and exhibit excellent hydrolysis resistance. That makes them ideal for oil filter housings, turbocharger inlet manifolds, and coolant pumps. Their inherent flame retardance (UL94 V‑0) often negates the need for additional additives, preserving material purity.

4.2 PA46 and PA9T in Thermal Management Systems

PA46 boasts a melting point above 290 °C and superior dimensional stability (HDT > 200 °C). It’s used in radiator end caps, heater valve bodies, and EV battery thermal interfaces. PA9T, with its aromatic backbone, offers low moisture uptake (≤ 1 %) and excellent electrical insulation—critical for high‑voltage connector housings.

5. Design and Processing Considerations

5.1 Mold Flow and Warpage Control

High‑fill grades like glass‑reinforced nylons and PPA require advanced flow simulation to optimize gate locations, wall thickness transitions, and cooling channel layouts. At YJCPolymer, our CAE team tunes mold designs to minimize knit lines and reduce warpage to less than 0.5 %.

5.2 Annealing and Post‑Crystallization

Semi‑crystalline polymers such as PA46 and PPA benefit from post‑mold annealing cycles (e.g., 2 hours at 180 °C) to relieve internal stresses and achieve target crystallinity—improving creep resistance and dimensional accuracy.

5.3 Additive and Color Matching

Whether it’s flame‑retardant fillers, UV stabilizers, or proprietary color concentrates, we customize formulations in our ISO 9001 and IATF 16949 certified labs to meet OEM specifications. Predictive color mapping ensures even pigments in translucent and opaque parts.

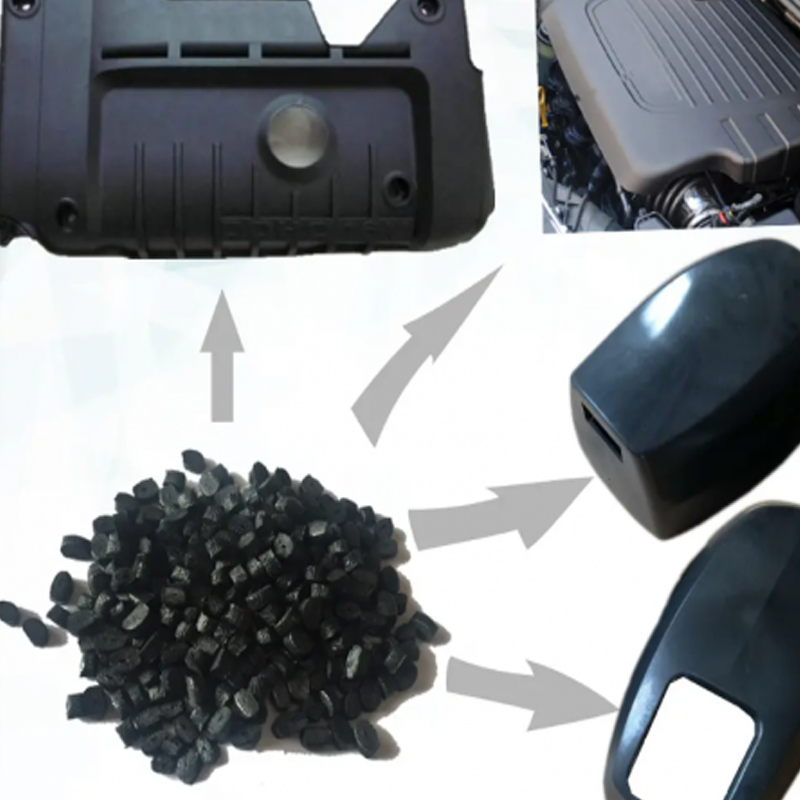

6. Sustainability and Lifecycle Benefits

- Recyclability: Thermoplastic composites can be reground and reprocessed up to three times without significant property loss.

- Weight Reduction: Every kilogram saved lowers CO₂ emissions by approximately 20 g per kilometer over the vehicle’s lifetime.

- Supply‑Chain Efficiency: Shorter cycle times and lower tooling costs accelerate time to market—minimizing inventory risks and logistics costs.

7. Why Partner with YJCPolymer?

At YJCPolymer, we combine material science expertise, in‑house compounding, and advanced molding technologies to deliver end‑to‑end polymer solutions:

- Consultative Engineering: From initial part feasibility to DFM workshops, we guide you through material selection and process optimization.

- Comprehensive Testing: Mechanical, thermal, and chemical property validation in our ISO/IEC 17025–accredited labs.

- Scalable Production: From prototype quantities to million‑part annual volumes, our network of global facilities ensures consistent quality and on‑time delivery.

- OEM Service Excellence: Full traceability, PPAP documentation, and aligned processes to automotive, aerospace, and consumer electronics standards.

Conclusion: Drive Innovation with Advanced Polymer Solutions

As the automotive industry accelerates toward lighter, more efficient vehicles, advanced engineering plastics—especially high‑temperature nylons and PPA—are poised to overtake metal in both under‑the‑hood and interior applications. By partnering with YJCPolymer, you gain a supplier capable of delivering turnkey, high‑performance polymer components that meet the most stringent regulatory and performance criteria.

Ready to discuss your next lightweighting or high‑temp polymer project? Contact us today for a free materials consultation and discover how our expertise can propel your designs into the future.