Overview:

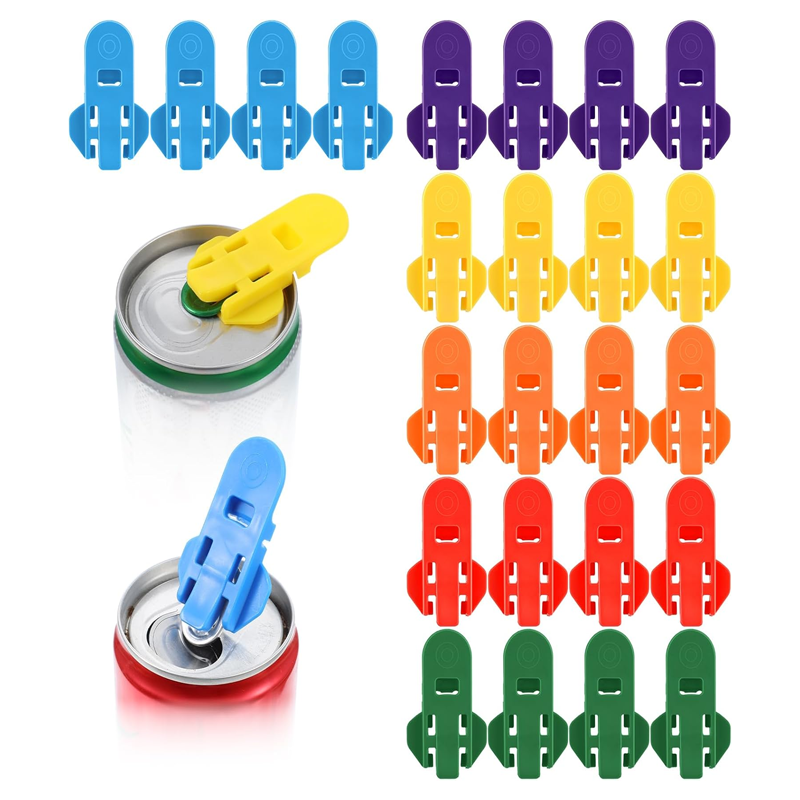

The Plastic Injection Molding PP Drink Can Easy Opener Protector Cap is a high-performance solution designed to provide both convenience and protection for beverage cans. Manufactured using premium PP (Polypropylene) plastic, this cap is engineered using advanced plastic injection molding techniques to achieve precise, consistent results. Ideal for use in the beverage industry, this protector cap offers a user-friendly, easy-to-open mechanism and protects the can’s contents from contamination and spills. With a secure fit and lightweight design, it ensures reliable sealing and ease of use. Our factory offers full OEM service, including custom sizing, color matching, and logo integration to meet your brand’s unique specifications.

Basic Information:

| Attribute | Details |

|---|---|

| Material | PP (Polypropylene) Plastic |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Color | Any Pantone Color |

| Packing | OPP bag, PVC box, color box, or customized |

| Logo | Customized Logo Accepted |

| Temperature Resistance | –20°C to +100°C |

| OEM | Available |

| MOQ | Small orders accepted |

| Sample | Can be provided |

| Technology | Plastic Injection Molding |

| Application | Beverage Industry |

Benefits of Our Product:

- User-Friendly Design: Easy to open, convenient to use, and prevents spills.

- Durable Performance: Made from high-quality PP plastic, ensuring long-lasting durability and stability.

- Cost-Effective Manufacturing: Produced with high efficiency using injection molding, optimizing production costs.

- Customizable Options: Tailored design, size, color, and logo options available to match brand identity and consumer needs.

Quality Assurance:

Our Plastic Injection Molding PP Drink Can Easy Opener Protector Cap undergoes rigorous quality assurance processes to ensure consistent performance and reliability. The manufacturing process is certified under ISO 9001 and adheres to the highest industry standards. Each product is subject to thorough material verification, dimensional accuracy checks using CMM systems, and stress testing for long-term performance. Additionally, we perform leak-proof assessments and functionality tests to ensure the lid fits securely and functions effectively under various conditions. Our dedicated quality control team uses advanced equipment such as digital calipers, tensile testers, and visual inspection systems to guarantee that every product meets customer expectations.

Surface Treatment Options:

- Smooth Finish: Provides a sleek, professional look and prevents buildup of dirt or residue.

- Custom Coating: Optional coatings for additional protection, such as UV-resistant coatings for extended outdoor exposure or antibacterial treatments for hygiene-sensitive applications.

Why Choose Us?

- Expertise in Injection Molding: With over 20 years of experience, we specialize in the production of high-quality, precision injection molded parts.

- Full Customization Services: Offering bespoke solutions in size, design, color, and branding, ensuring a perfect match with your product vision.

- Quality and Compliance: Our products are manufactured under strict quality controls, ensuring compliance with FDA, RoHS, and ISO 9001 certifications.

- Cost-Effective and Efficient Production: High-volume production capabilities ensure cost savings while maintaining quality and consistency.

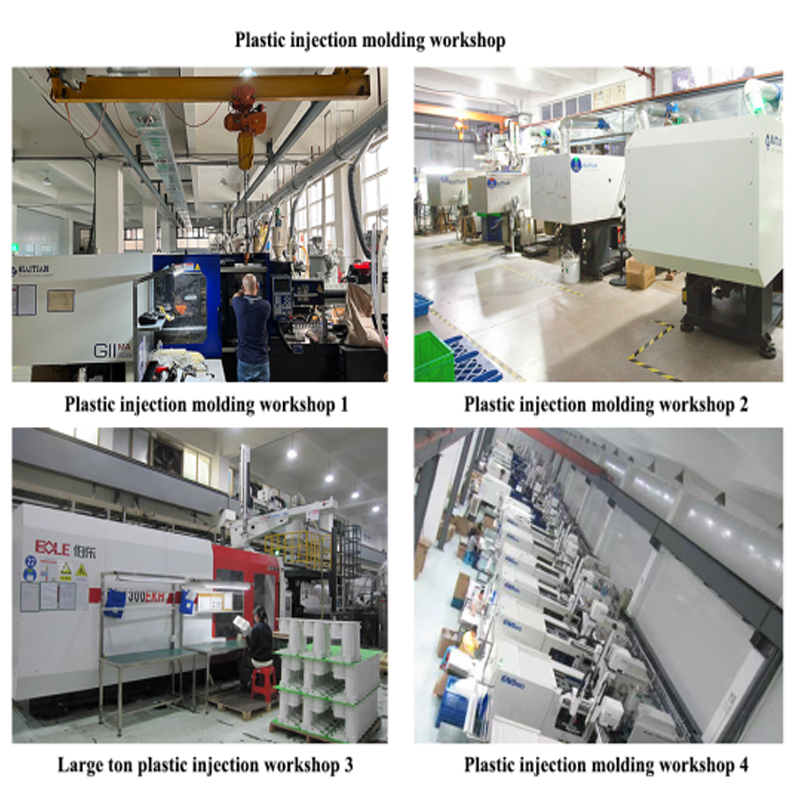

Factory Show:

Our state-of-the-art facility is equipped with advanced injection molding machines and automated production lines for maximum efficiency and consistency. We operate under ISO 9001 and IATF 16949 certifications, utilizing precision tooling, CNC machines, and automated inspection systems to guarantee product quality. Our quality control team utilizes a variety of inspection tools, including 3D optical projectors, seal testers, and durometers to ensure each product meets industry standards and customer expectations.

With our one-stop service, we offer rapid prototyping, design support, and custom manufacturing solutions tailored to the beverage industry’s needs. Whether you are looking for a specific color, material, or branding, our team is equipped to deliver outstanding products that meet the highest standards of performance and reliability.