Overview:

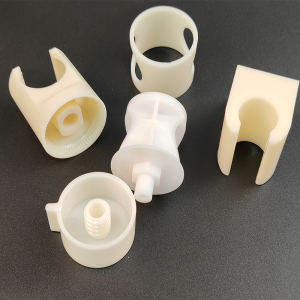

Our Personalized High Temperature-Resistant LSR Injection Molding Silicone Shower Nozzles are engineered for long-lasting performance and optimal functionality in high-temperature environments. Made from Liquid Silicone Rubber (LSR), these nozzles are crafted to provide exceptional heat resistance, durability, and flexibility, making them ideal for use in shower head replacements. Designed to meet the needs of residential and commercial applications, these shower nozzles are manufactured using advanced LSR injection molding processes to ensure consistent, precise dimensions and high-quality finishes. We offer custom solutions, including personalized designs, colors, and branding, to fit your specific product requirements. Whether you’re looking for prototyping or high-volume production, we provide comprehensive OEM services that guarantee top-tier performance and reliability.

![]()

Key Features:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Liquid Silicone Rubber (LSR) |

| Color Options | Custom colors available (Pantone matching) |

| Logo | Custom logo printing options available |

| MOQ | Small orders accepted |

| Sample Availability | Available upon request |

| OEM Service | Fully customizable |

| Temperature Resistance | -40°F to +450°F (up to 232°C) |

| Surface Finish | Smooth or textured options available |

| Application | Shower Head Replacement, Plumbing |

| Certification | ISO 9001, FDA, RoHS |

| Production Lead Time | 20–30 business days |

| Sample Lead Time | 5–7 business days |

Benefits of Our Products:

- High-Temperature Resistance

Designed to withstand high temperatures up to 450°F (232°C), making them ideal for use in shower heads exposed to hot water, ensuring long-lasting performance. - Durable and Flexible

Made from LSR (Liquid Silicone Rubber), these shower nozzles are highly flexible, durable, and resistant to cracking or wear, providing a long service life in high-stress environments. - Customizable Fit and Design

Available in a variety of custom sizes, colors, and textures, we offer tailored designs that meet your specific requirements. Custom logo imprinting is also available to help brand your products effectively. - Non-Toxic and Safe

Compliant with FDA standards and RoHS certified, these nozzles are made from food-grade, non-toxic materials, ensuring safety for use in daily shower applications.

Production Process:

- Design & Tooling:

We begin by designing the shower nozzle based on your specifications, followed by the creation of precise molds using CAD software and CNC machining to ensure accuracy. - Material Selection:

We use high-quality liquid silicone rubber (LSR), which provides excellent temperature resistance, flexibility, and durability, making it the ideal material for shower nozzle applications. - LSR Injection Molding:

The LSR is injected into custom molds using state-of-the-art injection molding techniques. This method ensures precise dimensions and consistent quality across every part produced. - Curing and Cooling:

After molding, the silicone is cured to achieve optimal durability and flexibility, followed by a cooling process to stabilize the shape and ensure the nozzle retains its form under pressure. - Surface Treatment:

Depending on your needs, surface treatments such as texturing or coating may be applied to enhance the nozzle’s grip, aesthetics, or resistance to wear. - Quality Control:

Every nozzle undergoes stringent quality checks, including dimensional verification using coordinate measuring machines (CMM), visual inspections, and functional testing to ensure the nozzles perform effectively in real-world applications. - Packaging & Delivery:

After passing quality control, the shower nozzles are packaged securely and prepared for shipping according to customer specifications.

Quality Assurance:

Our quality assurance process for LSR Injection Molding Silicone Shower Nozzles includes:

- Material Compliance: We use only FDA-compliant LSR that meets the highest food-grade standards.

- Dimensional Inspections: Precise measurements are ensured using coordinate measuring machines (CMM) and 3D optical scanners.

- Functional Testing: We test the nozzles for water flow efficiency, heat resistance, and flexibility to guarantee their performance in real-world conditions.

- Automated Vision Systems: Our automated vision systems provide precise defect detection, ensuring each nozzle is free of imperfections.

- Durability Testing: Each batch is tested for thermal cycling, chemical resistance, and long-term wear to ensure reliability over time.

Our ISO 9001 and IATF 16949 certified manufacturing facility ensures consistent, reliable production of the highest quality shower nozzles. All products undergo batch traceability and final QC checks in a controlled environment to meet industry standards.

Why Choose Us?

- Expertise in Silicone Molding:

With years of experience in silicone molding, we specialize in producing custom, high-performance products that meet industry standards. - Custom Solutions:

Our OEM services include fully customizable shower nozzles that fit your exact requirements in terms of size, color, texture, and branding. - State-of-the-Art Manufacturing:

Our manufacturing facility is equipped with advanced LSR injection molding technology and precision CNC machining equipment to deliver consistent and accurate products. - Certified Quality:

Our ISO 9001 and IATF 16949 certifications ensure that every product undergoes rigorous quality control to meet the highest standards of performance and safety.

Factory Show:

Our factory integrates the latest technologies, including CNC machining, Mirror EDM, and precision wire cutting, ensuring exceptional precision in mold fabrication. We operate 15 rubber compression molding presses and 2 LSR injection molding units, ensuring high-volume production with consistent quality. Our quality control is backed by 3D projectors, sealing testers, durometers, and elasticity gauges, ensuring every product meets the required specifications.