Overview:

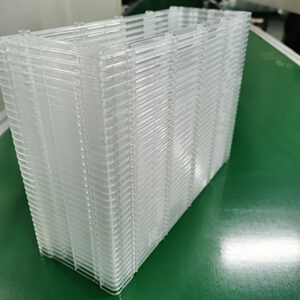

OEM Precision POM Gears and Transmission Parts for the Auto Industry are high-performance drivetrain components crafted from premium polyoxymethylene (POM) using precision CNC gear hobbing and high-accuracy injection molding. These parts deliver exceptional wear resistance, low friction, and tight tolerances essential for modern automotive transmissions. As experienced manufacturers, we offer full one-stop service—from engineering design and rapid prototyping to tooling, molding, and finishing—and comprehensive custom service for bespoke gear profiles, material grades, and performance specifications. Get in touch today to discuss your requirements and request a quote or sample!

Basic Information:

| Specification | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | High-performance Polyoxymethylene (POM) |

| Manufacturing Process | Precision CNC Gear Hobbing & Injection Molding |

| Color | Natural POM (Custom Dyeing Available) |

| Logo Printing | Laser Engraving or Pad Printing |

| Sample | Available Upon Request |

| Certification | ISO 9001, IATF 16949 |

| Tolerance | ±0.01 mm (Custom Tolerances Supported) |

| MOQ | According to Your Requirements |

| Lead Time | 20–30 Days (Dependent on Complexity & Volume) |

| Surface Finish | Smooth Polished or Matte Textured, per Customer Specification |

Key Advantages of Our Components:

- Ultra-Tight Dimensional Control

High-precision CNC gear hobbing achieves tolerances down to ±0.01 mm, ensuring perfect gear alignment and smooth power transfer throughout the drivetrain. - Consistent High-Volume Output

State-of-the-art injection molding delivers repeatable, flash-free parts with minimal scrap, enabling scalable production runs without compromising quality. - Exceptional Wear Durability & Low Friction

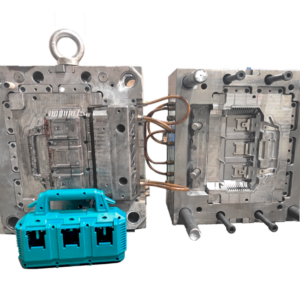

Engineered from premium POM resin, our gears offer superior abrasion resistance and a low drag coefficient, extending service life and improving transmission efficiency. - Custom Tooling & Rapid Iteration

Modular mold architectures and quick-change inserts facilitate bespoke gear geometries, branded engravings, and material variations—accelerating your time-to-market.

Custom Service:

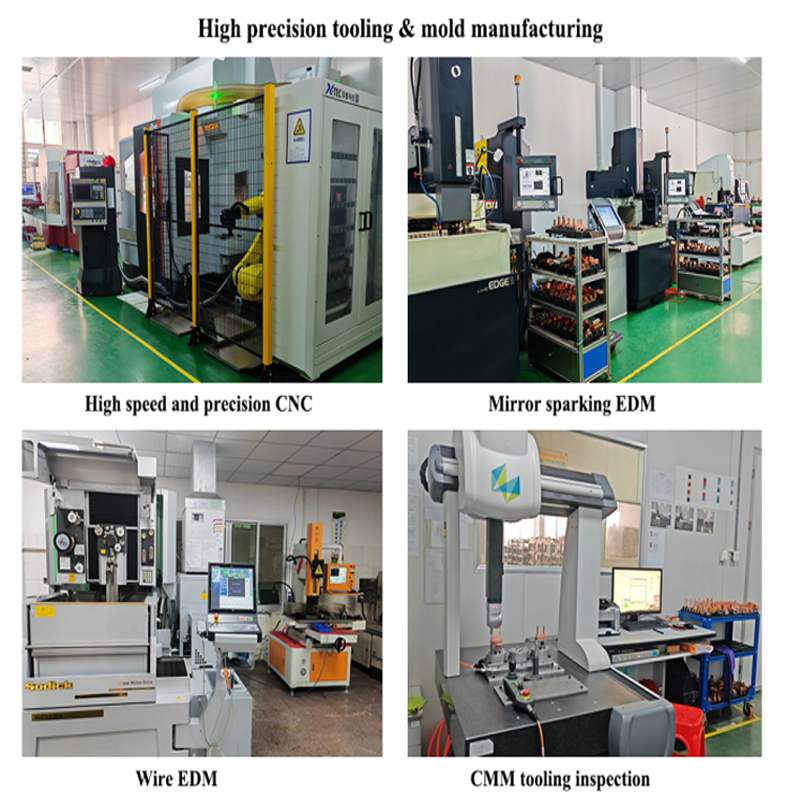

We provide end-to-end custom gear manufacturing services, starting with in-depth requirements analysis to define geometry, materials, tolerances, and performance criteria. Our team delivers precise CAD designs and rapid prototypes via CNC or additive manufacturing for validation. Precision tooling is developed using advanced CNC and EDM processes, followed by pilot production for process verification and sample approval. Full-scale manufacturing is executed with rigorous in-process monitoring, CMM inspections, and material testing to ensure specification compliance. Finally, we offer tailored packaging, logistics coordination, and inventory management solutions to seamlessly support your supply chain needs.

Quality Assurance:

Our quality assurance program for Custom Precision POM Gears and Transmission Parts is built on ISO 9001 and IATF 16949 automotive standards, ensuring strict adherence to performance and reliability benchmarks. Dimensional accuracy, with tolerances up to ±0.01 mm, is verified through advanced coordinate measuring machines (CMM) and specialized gear measurement systems. Material characteristics are assessed using durometers for hardness and tribometers for evaluating friction and wear behavior. Real-time process monitoring integrates digital pressure and temperature sensors within injection molding operations. Additionally, finished products are subjected to tensile strength and fatigue life testing to validate mechanical durability. Automated vision systems meticulously inspect for surface imperfections and molding anomalies, delivering consistently high-precision components tailored to the exacting demands of contemporary automotive systems.

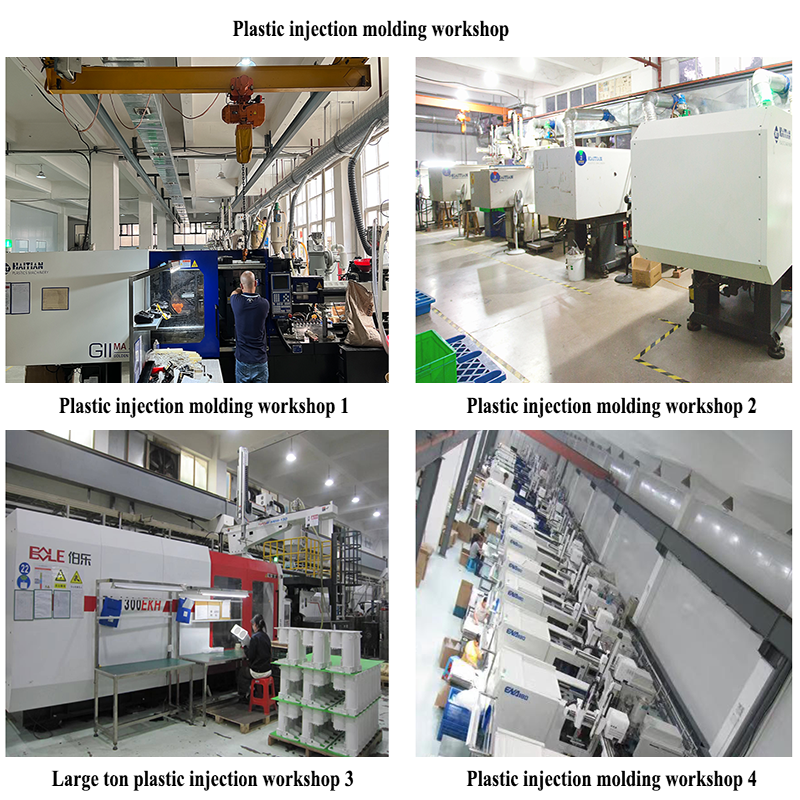

Factory Show:

Our advanced manufacturing facility integrates high-precision CNC machining, mirror-finish and conventional EDM, alongside ultra-fine, slow-speed wire-cutting technology to achieve exceptional mold accuracy and process consistency. The molding division is equipped with 15 rubber compression presses and two high-performance LSR injection machines, enabling scalable, high-volume production without compromising on stringent quality standards. A certified quality assurance team conducts comprehensive in-house inspections utilizing 3D optical projectors, sealing integrity testers, Shore hardness meters, and elasticity gauges to validate the integrity and performance of every component. Fully certified to ISO 9001 and ISO 13485, our operation prioritizes meticulous process control and product uniformity. To optimize production efficiency and maintain consistent quality, we employ automated AutoDryers, rapid doming systems, and precision die-cutting equipment throughout our manufacturing workflow.