Specification

Specification

Brand Name: Customized

Packaging Details: Wooden case, Carton

Material: Mild Steel, Stainless Steel, Aluminum

Technology: Progressive Die Mould

Certification: ISO9001

Application: Automotive, Electrical Appliances, Instrumentation, Aviation

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Delivery Term: By sea/Express

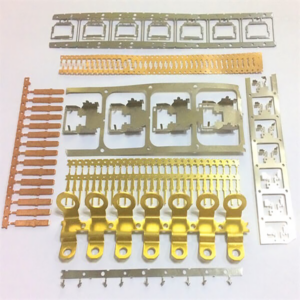

Our stampings are available in mild steel, stainless steel, and aluminum variants, allowing you to choose the material that best suits your application’s requirements. Utilizing Progressive Die Mould technology, we guarantee the utmost precision and consistency in every stamping. This ensures a reliable fit and function in your products. Our stampings adhere to rigorous quality standards and hold ISO9001 certification, assuring you of their quality and reliability in critical applications. These stampings find applications across a range of industries, including automotive components, electrical appliances, instrumentation devices, and aviation equipment. Their adaptability makes them a versatile choice for various engineering needs.

Terminal Stamping Processes

The terminal stamping process is a crucial aspect of sheet metal stamping. Sheet metal stamping is a precision manufacturing technique that employs a specialized die to cut or shape sheets of metal. Unlike other methods, this process typically does not involve the application of heat and is often referred to as cold stamping. It is also known as cold forming or metal stamping.

Precision Terminal Stamping Solutions

- Precision Stamping Dies: Our core strength lies in designing and producing progressive stamping dies. We excel in crafting precision terminals, connectors, contacts, clips, shrapnel, shells, and shielding covers. Our materials include cold-rolled steel, stainless steel, phosphor bronze, brass, red copper, beryllium copper, and lead frame materials, ensuring versatility to meet your exact specifications.

- Metal Stamping Expertise: Our advanced facilities house diverse precision presses, allowing us to manufacture coils and strips with exceptional accuracy and consistency. We are committed to delivering products that meet the highest industry standards, guaranteeing reliability for your applications.