Gaskets are indispensable components in a variety of applications and come in a wide variety of materials, carefully tailored to meet specific requirements and challenges. From sealing automotive components to ensuring the integrity of medical equipment and industrial machinery, gasket material selection plays a key role in achieving a secure fit with mating surfaces and preventing air leakage or liquid intrusion. YJCPOLYMER has been in-depth research and production of gaskets for many years. If you have any questions about gaskets, let us answer them for you. Let’s take a deeper look at each gasket type, dissect their unique properties and learn about their practical applications in various industries.

Rubber Gasket:

Rubber gaskets date back to 1844 and are widely used in automotive, industrial, medical and food processing fields, whether of natural origin or synthetically produced.

In the automotive industry, rubber gaskets play a vital role in sealing vehicle doors, trunk lids and preventing water ingress between engine block and cylinder head seals, ensuring optimal performance and longevity of vehicle components.

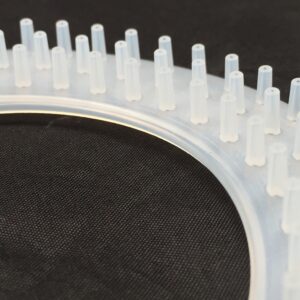

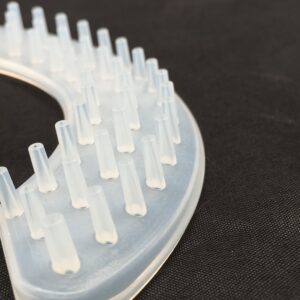

Silicone Gasket:

Invented in 1953, silicone gaskets contain silicon atoms in their molecular structure, providing exceptional durability and resistance to a wide range of chemicals.

Due to their inertness and ability to withstand extreme temperatures, silicone rubber gaskets are widely used in food processing applications and are also common in medical devices, where hygiene and compatibility with sterilization processes are critical.

EPDM Rubber Gasket:

Ethylene propylene diene monomer (EPDM) rubber gaskets offer high heat resistance, chemical resistance and flexibility, making them suitable for a variety of applications.

EPDM gaskets are widely used in automotive parts, industrial products, medical equipment, construction and electronics where adaptability and reliability to environmental factors are critical.

Neoprene Gasket:

Neoprene gaskets are derived from polychloroprene and have excellent elasticity and flexibility, retaining their shape during continuous movement and conforming well to irregular surfaces.

Neoprene gaskets are commonly used in medical devices where seal integrity and durability are critical, providing reliable performance under demanding conditions.

Foam Gasket:

Foam gaskets are composed of layers of closed-cell polyurethane foam that provide excellent thermal conductivity and sound absorption properties.

Foam gaskets are widely used in applications requiring thermal insulation and sound absorption, providing an effective solution for minimizing heat transfer and reducing noise levels across industries.

O-Ring Gasket:

O-rings consist of a metal ring that expands outward when pressure is applied between objects, creating a reliable seal.

O-ring gaskets are often used to seal shafts or rotating parts in machinery to prevent leakage and contamination and ensure the smooth operation of mechanical systems.

PTFE Gasket:

Polytetrafluoroethylene (PTFE) gaskets offer excellent chemical resistance, low friction, high temperature stability and non-reactivity.

PTFE gaskets are commonly used in food processing, pharmaceutical manufacturing, semiconductor manufacturing and medical equipment, providing superior reliability in harsh environments where contamination and chemical exposure must be minimized.

EMI Shielding Gasket:

EMI shielding gaskets are made of metal alloys and damping materials to prevent signal interference in electronic devices.

EMI shielding gaskets are critical in ensuring that sensitive electronic components are protected from external signals that could disrupt their operation, playing a vital role in maintaining the integrity and reliability of electronic systems.

While these eight types represent a broad range of gasket materials, the diversity of the category provides engineers and designers with a wide range of options to meet the specific needs and challenges of each industry. Whether ensuring a hermetic seal in automotive applications or protecting sensitive electronics from electromagnetic interference, choosing the right gasket material can help achieve optimal performance and reliability in diverse environments. Washers are widely used, but how to choose a supplier? Please leave it to YJC Polymer. Our factory’s manufacturing capabilities enable us to produce high-volume gaskets for different industries and functions.