Hi, we meet again. How’s it going? We’ve been talking about LSR-related content for the past few days, and today we’re going to talk about Metal Stamping-related topics. In fact, Metal stamping is also used in our various industries, and its importance can be seen. As you guys know, it’s getting close to the end of the month, and I wanted to ask if you guys have considered working on metal stamping? And if you have, how I wish the partner you are considering is us. Well, let’s get into today’s topic!

First I want to ask you a question:is precision metal stamping the optimal solution for your project? This question is multifaceted, requiring consideration of various factors. Renowned for its precision and speed, the suitability of precision metal stamping hinges on project goals, encompassing factors like costs, time constraints, and potential alterations. Below, we delineate the precision metal stamping process along with its advantages and disadvantages.

What is Precision Metal Stamping?

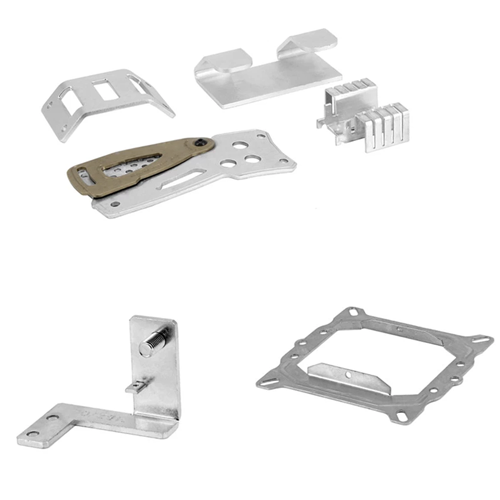

Precision metal stamping revolves around meticulous measurements and leveraging automation to efficiently produce large volumes of specific springs or metal components. Fabricators input precise measurements and specifications, resulting in accurately designed products at a rapid pace. This method, encompassing approaches like progressive die stamping, is prevalent in industries such as aerospace, appliance manufacturing, medical products, automotive, gas, and oil. The accompanying image illustrates the utilization of metal stamping in automotive manufacturing. The refined material showcased not only enhances the aesthetic appeal but also plays a crucial role in elevating the overall performance of the vehicle.While the qualities of accuracy and speed are advantageous, the suitability of precision metal stamping depends on careful consideration of budget, deadlines, and prototype requirements for optimal fabrication outcomes.

What benefits does Precision Metal Stamping offer?

- Accuracy:Achieves precise measurements and designs.

- Efficiency:Automated processes enable high-volume production.

- Versatility:Applicable in aerospace, automotive, medical, and more.

- Speed:Rapid production for time-sensitive projects.

- Cost-Effectiveness:Optimizes material usage, reducing costs.

What are the drawbacks of precision metal stamping?

The drawbacks of precision metal stamping primarily manifest when dealing with prototypes or limited productions. The cost-effectiveness of this process hinges on mass production, making the creation of single prototypes or occasional units comparatively less economical. It is advisable to consult with a reliable metal stamping company to develop a strategic plan that aligns with specific production needs.

Feel prepared to determine if precision metal stamping suits your project? Reach out to us today. If you’ve already made up your mind, click on the “Contact Us” section to get in touch. I believe our products will be the perfect gift for your Christmas, lol.