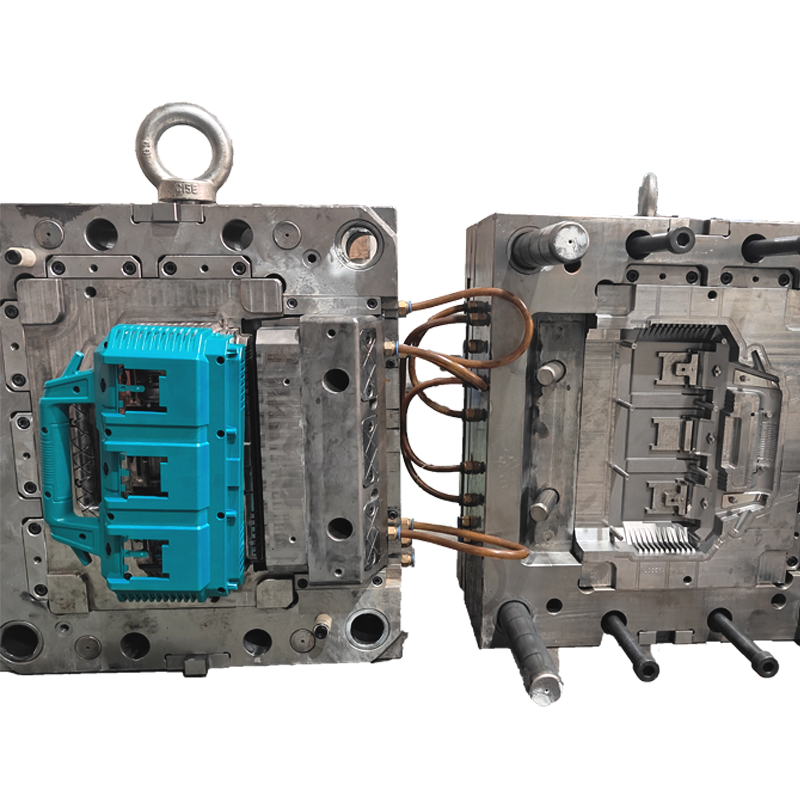

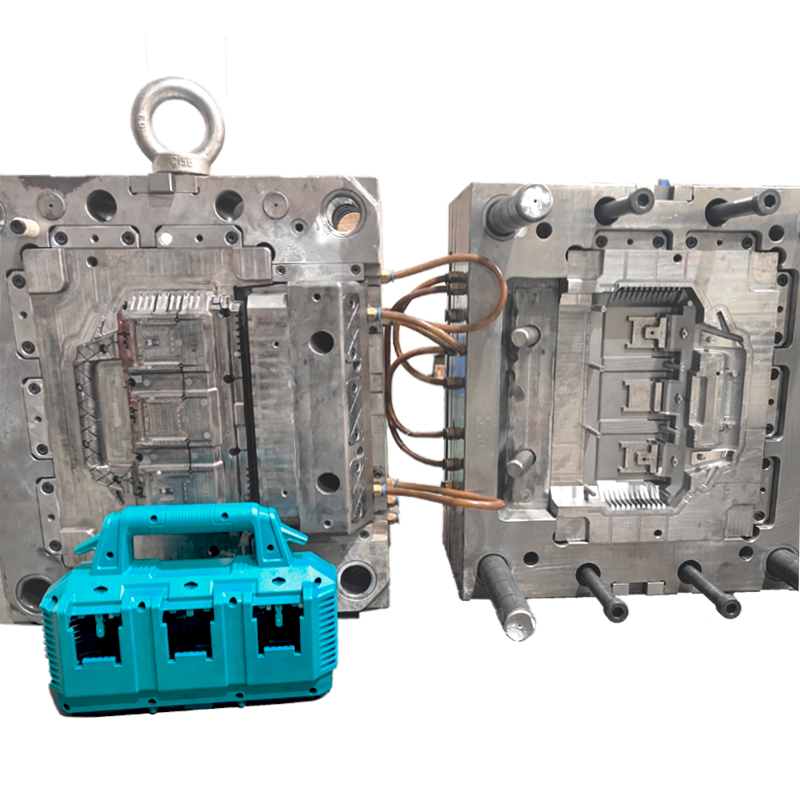

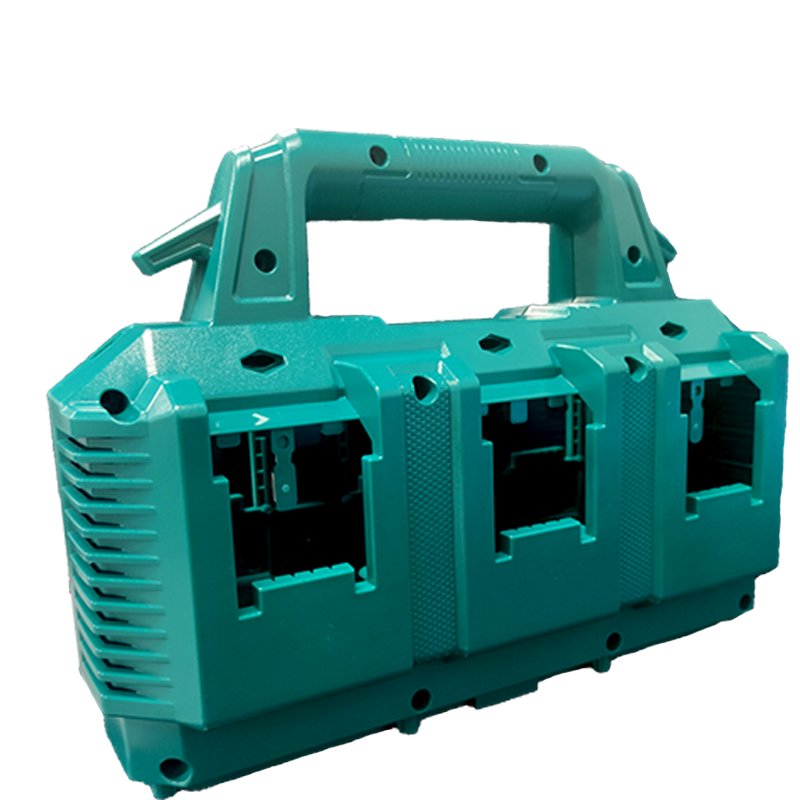

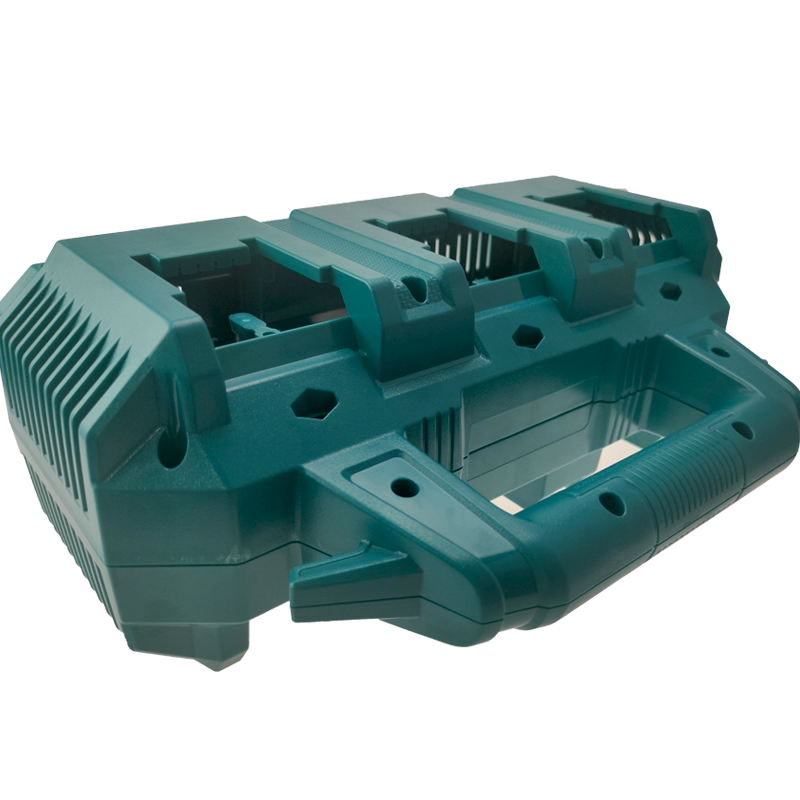

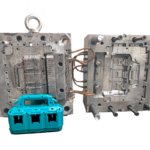

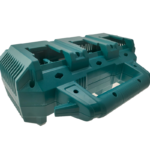

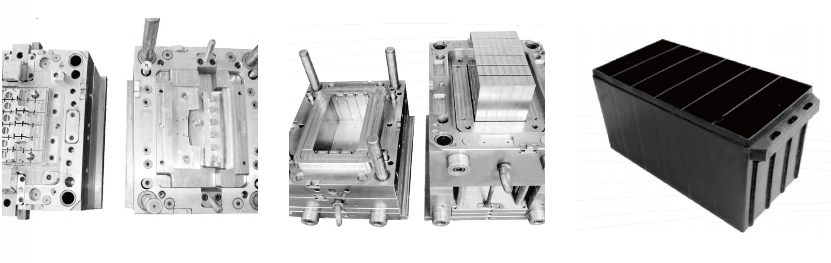

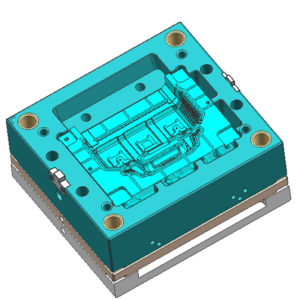

Outils pour boîtier de batterie - Moule en plastique pour boîte de batterie

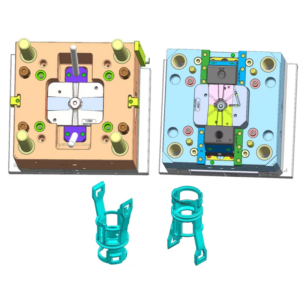

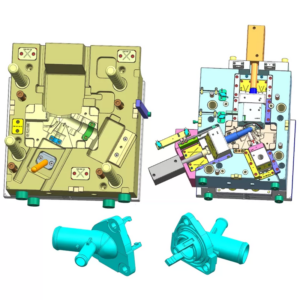

Les moules pour batteries de notre collection haut de gamme offrent la solution idéale pour répondre à tous vos besoins en matière de fabrication de batteries. Disponibles en tenant compte des batteries au plomb, des cellules lithium-ion et des options d'alimentation sans interruption (UPS), nos experts en fabrication de moules comprennent l'importance de trouver des moules adaptés spécifiquement à leurs environnements de travail et à leurs exigences.

Notre vaste collection de moules pour boîtiers de batteries comprend diverses séries adaptées à différents types de batteries. Pour les batteries automobiles, nous proposons des moules des séries N40, N50, N70, N100, N120, N150 et N200, offrant un ajustement parfait pour vos besoins spécifiques en matière de véhicules. Si vous avez besoin de batteries UPS, nos moules des séries 55AH, 90AH et 100AH sont conçus pour répondre de manière fiable à vos besoins en alimentation de secours. Pour les batteries d'onduleur, nous proposons les moules de la série IT 500, et pour les batteries DIN, nous avons les séries DIN55 et DIN66. De plus, nous sommes capables de créer des moules de boîtiers de batteries en plastique sur mesure selon vos spécifications uniques.

En tant que fabricant de moules pour pièces d'énergie nouvelle, nous avons de nombreuses années de connaissances et d'expérience professionnelles, en nous concentrant sur la fourniture de solutions de moules excellentes pour le domaine de l'énergie nouvelle. Nos capacités de conception et de fabrication de matrices sont conçues pour répondre aux besoins et spécifications spécifiques des clients, garantissant ainsi que ces derniers peuvent obtenir des pièces de haute qualité.

Notre service comprend :

- Conception de moules et support en ingénierie

- Sélection de matériaux et recommandations

- Fabrication de moules

- Développement de prototype

- Essai et Ajustement de Moule

- Livraison rapide

- Assurance Qualité

- Pratiques de durabilité

Capacité :

- Conception et Fabrication de Haute Précision

- Reproduction précise de géométries complexes

- Conception à multi-cavités pour une efficacité améliorée

- Matériaux et procédés de fabrication résistants à haute température

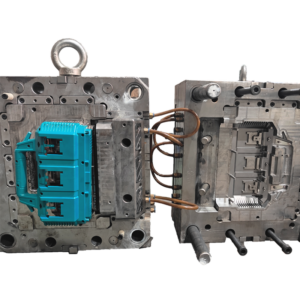

- Système de refroidissement de précision

- Longévité et Entretien

- Système de contrôle qualité

Types d'outillage

1. Outils de prototypage

L'outillage de prototype, également connu sous le nom d'outillage souple ou d'outillage rapide, est le processus par lequel des outils sont conçus, produits et testés pour leur adéquation, leur forme et leur fonction en préparation du processus de production. Au cours du processus de prototypage, les fabricants peuvent ajuster le design plusieurs fois pour atteindre une performance et une finition optimales. Certains matériaux souvent utilisés dans le prototypage sont le caoutchouc silicone, les alliages d'aluminium et l'acier doux en raison de leur coût inférieur ; ils sont généralement plus rapides et plus faciles à façonner. Les avantages de l'outillage de prototype comprennent :

- Crée des prototypes rapidement, prenant souvent seulement quelques heures ou quelques jours plutôt que plusieurs semaines.

- Investissement plus petit, permettant des essais pour vérifier les défauts de conception, les tolérances, et plus encore.

- Des pièces précises peuvent être produites.

2. Outils de production

Le prototypage d'outillage, également appelé outillage léger ou outillage rapide, permet aux fabricants de concevoir, produire et tester des outils afin d'évaluer l'adéquation, la forme et la fonction avant la production à grande échelle. Des matériaux tels que le caoutchouc silicone, l'alliage d'aluminium et l'acier doux sont couramment utilisés en raison de leur rentabilité et de leur facilité de mise en forme. Les avantages incluent une production rapide de prototypes en quelques heures ou jours, des coûts d'investissement réduits, et la possibilité de produire des pièces précises pour des tests et une validation.

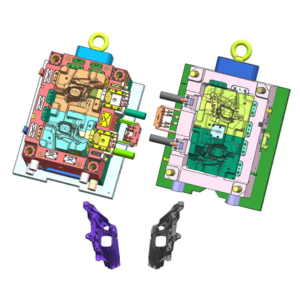

Processus de fabrication de moules

- La vérification du produit 3D et l'analyse DFM (Design for Manufacturing)

- Conception des outils et obtention de l'approbation.

- Achat de matériau pour moules

- "Bâtiment audacieux du processus CNC et EDM.

- Usinage auxiliaire tel que l'électroérosion à fil, le perçage et le meulage.

- Polissage

- Assemblage de moules

- Contrôle de qualité

- Échantillon T0 et P0 pour approbation du client.

- Emballage et livraison

Taux de tolérance serrés

En utilisant l'EDM par fil, la CNC à 5 axes et d'autres équipements de haute précision pour atteindre des tolérances de 0,01 mm.

Machines de fabrication d'outillage principal

| Machinerie | Quantité |

| Vitesse élevée de 42000 et précision CNC | 2 |

| Autres 7 machines CNC | 7 |

| Makino EDM par enfoncement | 4 |

| Sodic Usinage par Fil EDM | 5 |

| Meuleuse de haute précision | 5 |

Matériaux

- P20 (P20HH)

- S136 (S136H)

- NAK80

- H13

- 718 (718H)

- 2738 (P20+Ni)

- 2316

- MoldMAX

- Aluminium

Pourquoi nous choisir pour votre fabrication d'outillage ?

1. Équipement et technologie avancés

Nous disposons d'équipements et de technologies de fabrication avancés, y compris des machines CNC de haute précision, des logiciels CAO/FAO et des technologies d'impression 3D. Ces outils avancés nous permettent d'atteindre une fabrication précise des outillages et de réaliser des détails complexes et des formes sophistiquées avec une précision maximale.

2. Support en conception et ingénierie sur mesure

Nous travaillons en étroite collaboration avec nos clients, acquérant une compréhension approfondie de leurs besoins et de leurs exigences en matière de produits. Notre équipe d'ingénieurs expérimentés fournit des conseils en conception professionnelle et un soutien technique, garantissant que la conception des outils répond aux attentes des clients et aux exigences spécifiques des produits.

Matériaux de haute qualité et normes de fabrication

Nous sélectionnons rigoureusement des matériaux de haute qualité pour nos outils, tels que de l'acier de qualité supérieure et des alliages résistants à l'usure. De plus, nous respectons des normes et des processus de contrôle qualité stricts afin d'assurer la qualité et la cohérence de fabrication de chaque outil. Cela contribue à améliorer la durabilité, la stabilité et la durée de vie des outils.

4. Innovation technologique et amélioration continue

En tant qu'usine axée sur l'innovation et en constante amélioration, nous poursuivons sans relâche l'innovation technologique, en explorant de nouvelles méthodes et matériaux de fabrication. En intégrant des processus et des technologies avancés, nous améliorons la précision, la complexité et l'efficacité de production de nos outils pour répondre aux exigences du marché en constante évolution.