Product Description

Product Description

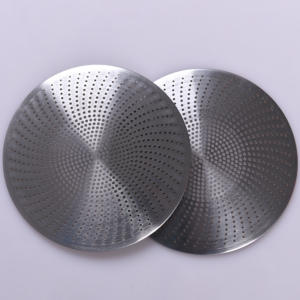

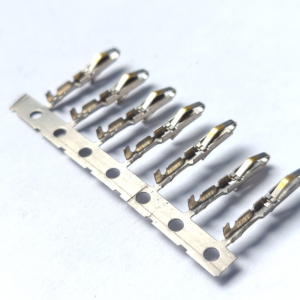

Precision-engineered for excellence, our Customized Stainless Steel Metal Stamping Parts, including Electronic Contacts and Clips, are crafted from a versatile range of materials, including alloy steel, stainless steel, aluminum, brass, zinc, iron, copper, and customized raw materials. Our state-of-the-art surface processing techniques, such as brushing, hot galvanizing, oxidation, powder coating, and spraying, ensure optimal performance and longevity. With wire diameters ranging from 0.004’’ (0.1mm) to 6.0’’ (6.0mm) and tolerances as tight as 0.01mm-0.2mm, these precision-engineered components find their niche in industrial, electronic, communication, machinery, and equipment applications. Explore the versatility of our U-shaped spring clips, each designed to meet specific requirements, showcasing our expertise in delivering tailored solutions.

Key Specifications:

- Type: U shape spring clip

- Material: alloy steel, stainless steel, aluminum, brass, zinc, iron, copper and customized raw material

- Surface Processing: brushing, hot galvanized, oxidation, powder coating, spraying

- Wire Diameter: 0.004’’(0.1mm)to 6.0’’(6.0mm)

- Tolerance: 0.01mm-0.2mm

- Customized design: according to customer’s drawing or special requires

- Features: no burrs, anti-corrosion, no deformation

- Certifications: ISO 9001

- OEM/ODM: available

- Capability: Compression Spring, Wire Bend form Spring Hook, Torsion Spring, Extension Spring,

- Application: industrial electronic communication machinery and equipment

Surface Finish

- Plating: Applying a metallic layer (e.g., zinc, nickel, chrome, tin, brass, gold, silver, titanium) to improve appearance and corrosion resistance.

- Black Oxide: Forming an oxide layer on metal surfaces to enhance corrosion resistance and change color.

- Hot-dip Galvanizing: Immersing metal in molten zinc to improve corrosion resistance.

- Powder Coating: Spraying powdered coating material onto surfaces for durability.

- Paint Coating: Applying liquid paint or coating for protection and aesthetics.

- Anodizing: Electrochemically forming an oxide layer to enhance corrosion resistance and alter color.

- Phosphating: Coating metal surfaces with phosphate salts to improve properties.

- PAD Printing: A technique for imprinting images or text on irregular surfaces.

- Laser Etching: Using a laser beam to create patterns, logos, or text on surfaces.

Application

Our Customized Stainless Steel Metal Stamping Parts, featuring Electronic Contacts and Clips, are purpose-built for precise applications within the industrial, electronic, communication, and machinery and equipment sectors. These meticulously crafted components excel in diverse roles, including ensuring robust electrical connections in electronic devices, enhancing the operational efficiency of industrial machinery, and optimizing the functionality of communication equipment. With their exceptional quality and reliability, our components are trusted by professionals to meet the exacting demands of these industries, delivering top-notch performance and durability for critical applications.