Description:

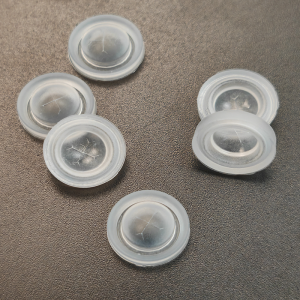

Our Customized Liquid Injection Molding Food Grade Silicone Valves with Cross Slit Cut for Dispensing Caps are expertly engineered to provide efficient, leak-proof dispensing for a wide range of liquids, including condiments, sauces, and dressings. Made from 100% FDA-approved, food-grade silicone, these valves are designed using precision liquid injection molding techniques, ensuring optimal flow control and durability for long-term use. The cross-slit cut design guarantees precise, one-way dispensing functionality, minimizing product waste and improving user experience. These silicone valves are perfect for use in dispensing caps, offering a reliable, clean, and controlled dispensing action without any leakage.

Ideal for high-volume manufacturing, our cross slit silicone valves are designed to handle a wide range of temperatures from –40°F to 450°F and are fully dishwasher-safe for easy maintenance. They comply with the highest food safety standards, including LFGB and FDA certifications, and are crafted with the goal of reducing single-use plastics while offering superior performance.As a trusted silicone manufacturing partner, we provide custom OEM solutions, offering tailor-made valve designs, custom colors, and logo imprinting to meet your specific product needs. We are committed to helping you elevate your brand with sustainable and innovative silicone products.

![]()

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Food-grade silicone |

| Valve Type | Cross Slit Cut |

| Certifications | ISO, FDA, LFGB |

| Packaging | Custom packaging solutions |

| OEM Services | Fully supported |

| Primary Use | Dispensing caps for liquids (e.g., condiments, sauces) |

| Sample Lead Time | 5–7 business days |

| Sample Availability | Available upon request |

| Production Lead Time | 20–25 business days |

| Temperature Range | –40°F to 450°F |

Benefits of Our Products:

- FDA and LFGB Approved Food-Grade Silicone: Safe for direct contact with food and fully compliant with the highest safety standards.

- Cross Slit Cut Design: Provides consistent, controlled dispensing with minimal waste and no leakage, ensuring a clean, smooth operation every time.

- High-Temperature and Low-Temperature Resistance: Suitable for a wide range of applications, including hot and cold dispensing environments.

- Leak-Proof & One-Way Functionality: Prevents leakage and ensures only the desired amount of liquid is dispensed with every squeeze.

- Dishwasher Safe: Easy to clean, maintaining hygiene without compromising the valve’s integrity.

- BPA-Free & Eco-Friendly: Made from non-toxic materials, supporting your efforts to reduce single-use plastics and providing a sustainable packaging solution.

- Customizable Designs: Tailor-made to meet your specific packaging needs, with custom sizes, colors, and logo imprinting.

- Cost-Effective: Factory-direct pricing for large-volume production with fast delivery.

- Free Samples: Available for quality testing and evaluation before large orders are placed.

Quality Assurance:

Our Customized Liquid Injection Molding Food Grade Silicone Valves with Cross Slit Cut for Dispensing Caps undergo a strict quality assurance process to ensure optimal performance and durability:

- Material Inspection: Only FDA-approved, BPA-free, food-grade silicone is used, ensuring compliance with both FDA and LFGB standards.

- Precision Molding: The valves are manufactured using liquid injection molding, which guarantees consistency and precision in the valve’s cross-slit design.

- Leak-Proof Testing: Every valve undergoes leak-proof testing to ensure that it provides a secure, airtight seal, eliminating the risk of spillage.

- Durability and Heat Resistance: We perform extensive high-temperature aging tests, flexibility testing, and tear resistance tests to ensure the valve’s long-lasting functionality.

- Dimensional Accuracy: Using CNC machining and coordinate measuring machines (CMM), we ensure each valve meets the exact dimensions required for your dispensing cap application.

- Final QC Inspections: Every batch of silicone valves undergoes a final quality control check to ensure compliance with industry standards and client specifications.

Our ISO 9001-certified facility guarantees that all valves are produced with the highest levels of consistency, safety, and performance.

Why Choose Us?

- Industry Expertise: With over two decades of experience in silicone manufacturing, we specialize in delivering precision-engineered solutions that exceed industry benchmarks for performance, reliability, and durability.

- Fully Customizable OEM Solutions: From component design to custom branding, we provide end-to-end OEM solutions tailored to your specific needs, whether for high-volume production or small-batch custom orders.

- Streamlined, Efficient Process: Our manufacturing process is designed to be transparent and efficient, ensuring rapid prototyping, on-time delivery, and responsive communication throughout the project.

- Certified Quality Assurance: Our ISO 9001 certified quality management system, coupled with state-of-the-art testing protocols, ensures consistent, high-quality products with every batch.

- Eco-Friendly Manufacturing: Our silicone valves are designed with sustainability in mind, reducing plastic waste and promoting environmentally responsible packaging solutions.

Factory Show:

Our state-of-the-art manufacturing facility is equipped with the latest technologies to ensure precision and efficiency throughout the production process:

- Liquid Injection Molding: Advanced injection molding techniques are used to create valves with perfect cross-slit cuts, ensuring precise flow control.

- CNC Machining & EDM: For accurate tool fabrication and consistent valve quality, we employ CNC machining and mirror EDM for high precision.

- Inspection Technology: We utilize 3D optical projectors, sealing testers, durometers, and elasticity gauges to ensure each valve meets the required standards.

- Automated Systems: Automated high-speed doming machines and precision die-cutting systems enhance production speed and consistency while maintaining product quality.

Our factory is ISO 9001 certified, ensuring the highest standards of quality control and compliance with the most stringent industry requirements. We leverage automated production lines to optimize efficiency and output consistency, ensuring a smooth and reliable manufacturing process for high-volume orders.Customized Liquid Injection Molding Food Grade Silicone Valves with Cross Slit Cut for Dispensing Caps are the ideal solution for creating high-performance, eco-friendly dispensing systems. Contact us today to learn more about our custom solutions, and request a free sample for quality evaluation. Let us help you elevate your product’s dispensing experience with precision-engineered silicone valves that ensure performance, durability, and sustainability.