Overview:

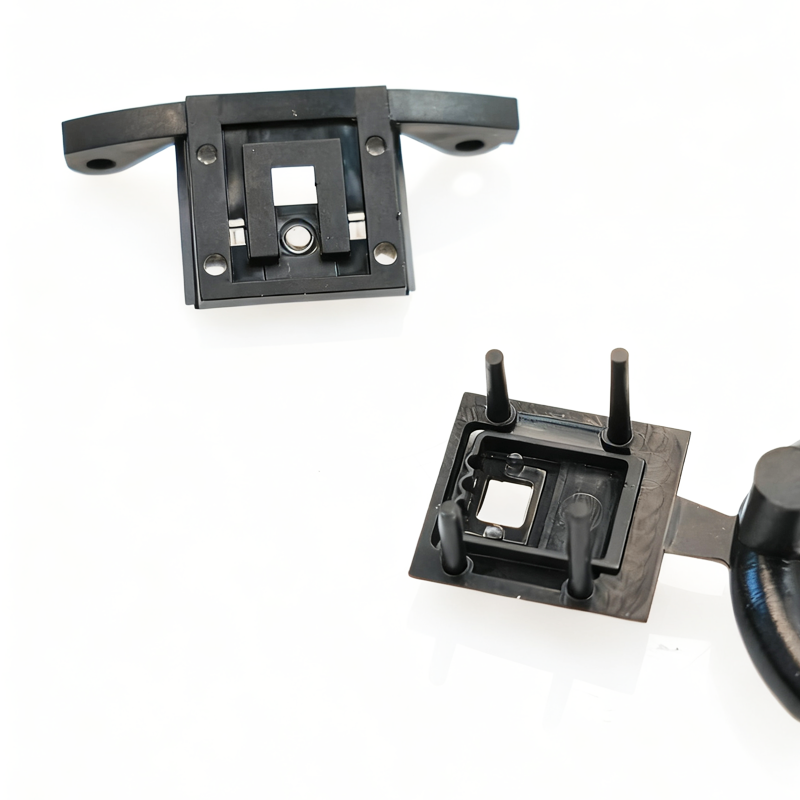

Custom Two-Shot Injection Molding PC & Acrylic Oximeter Lens Covers are high-precision optical components specifically designed for medical and wearable healthcare devices, such as pulse oximeters and SpO₂ monitors. These lens covers integrate two premium optical-grade materials—polycarbonate (PC) and acrylic (PMMA)—in a single molded structure using advanced two-shot (2K) injection molding technology. The process ensures exceptional bonding strength, superior optical clarity, and reliable durability while eliminating secondary assembly steps. Ideal for demanding medical environments, our lenses offer outstanding impact resistance, UV stability, and scratch protection. As a professional OEM manufacturer, we provide full customization options, from mold design and material selection to coating applications and logo marking, supporting both prototype and large-scale production with medical-grade compliance.

Features:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Optical-Grade Polycarbonate (PC) + Acrylic (PMMA) |

| Technology | Two-Shot (2K) Injection Molding |

| Surface Finish | Glossy / Matte / Anti-Reflective (Optional) |

| Customization | Dimensions, Color, Coating, and Marking Available |

| Sample | Available for Evaluation |

| Certification | ISO 9001, ISO 13485, RoHS |

| Tolerance | ±0.02 mm |

| Application | Medical Oximeters, Wearable Devices, and Monitoring Instruments |

Benefits of Our Products:

- Two-Shot Integration – Combines PC and PMMA in one precise molding cycle, ensuring strong adhesion and dimensional accuracy.

- Superior Optical Clarity – Acrylic layer provides crystal-clear transparency for precise light transmission in medical sensors.

- Durable and Impact-Resistant – Polycarbonate substrate delivers mechanical strength and high resistance to cracking or deformation.

- Customizable Surface Options – AR, anti-fog, or scratch-resistant coatings available to enhance performance and usability.

- Medical-Grade Manufacturing – Produced in ISO 13485–compliant conditions with full material traceability and FDA-approved resins.

Quality Assurance:

Every PC & Acrylic Oximeter Lens Cover undergoes a rigorous, ISO-certified quality management process. We utilize optical transmission analyzers, haze meters, coordinate measuring machines (CMM), and microhardness testers to ensure each lens meets optical and dimensional precision requirements. Surface integrity is verified through spectrophotometry and adhesion tests for coating durability. Our processes fully comply with ISO 9001 and ISO 13485 standards, ensuring biocompatibility, UV resistance, and long-term optical stability. Each production batch is traceable with full documentation, supporting OEM clients in regulated medical markets.

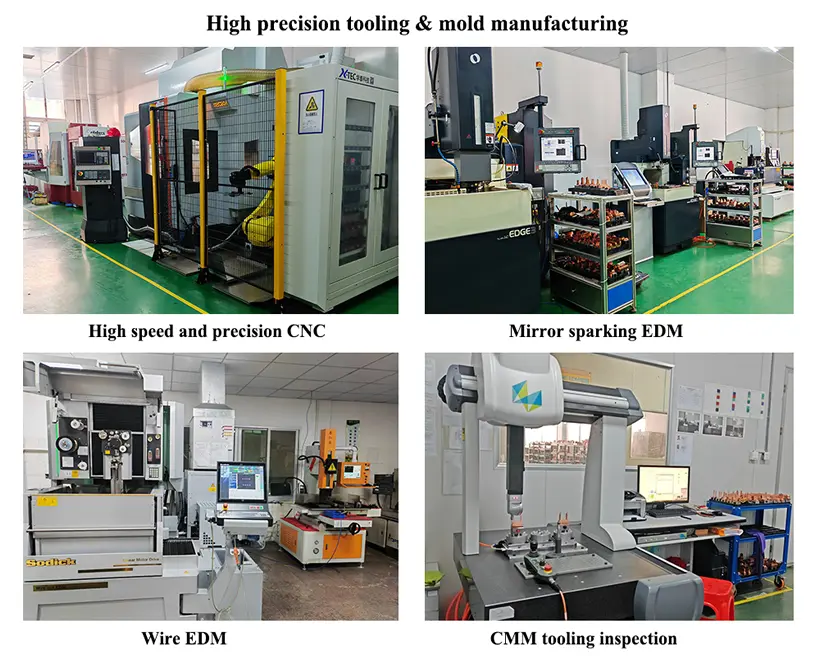

Our Factory:

Our advanced manufacturing facility is equipped with precision CNC machining centers, Mirror EDM, high-speed milling, and slow-speed wire cutting systems to produce high-quality molds with optical-grade finishes. We operate multiple two-shot (2K) injection molding machines, enabling simultaneous molding of PC and PMMA materials with micron-level precision. Automated polishing, coating, and laser-marking equipment are integrated into our production lines to ensure optical uniformity and branding flexibility. Backed by ISO 9001 and ISO 13485 certifications, our expert engineering and QC teams ensure each lens cover meets the strictest medical industry requirements for clarity, performance, and reliability.