Overview:

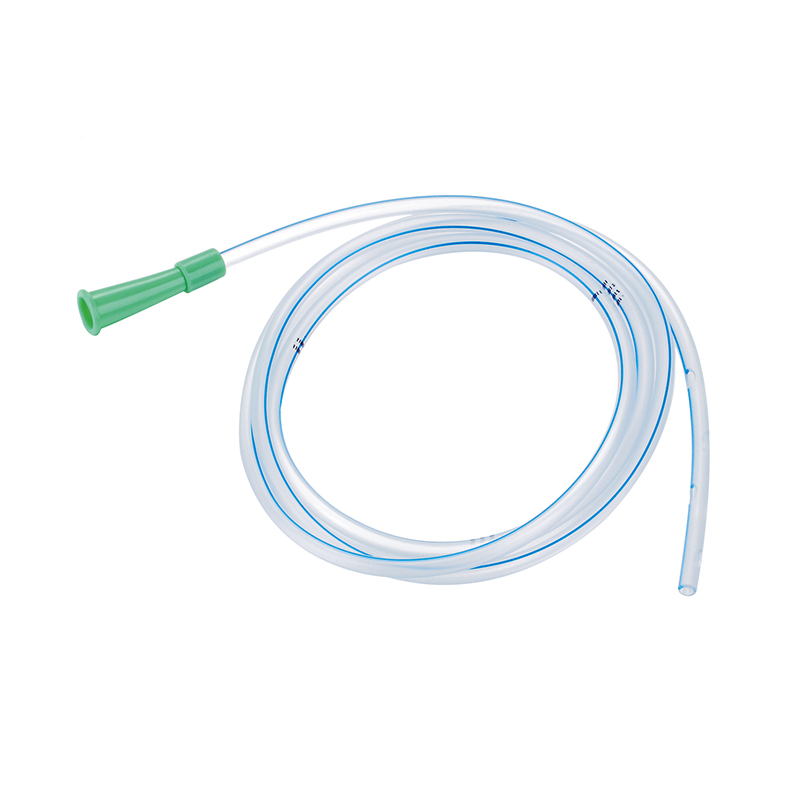

Custom Medical Grade Stomach Tube for Emergency Surgical Application is a high-performance medical device designed for critical use in emergency surgeries. Made from medical-grade, biocompatible materials, such as high-quality silicone or thermoplastic elastomers (TPE), these Stomach tubes are produced using precision molding techniques to ensure consistent quality, durability, and patient safety. Our factory offers OEM services, providing fully customizable solutions to meet specific design and functional requirements. We are certified to ISO 13485 and FDA standards, ensuring that our products meet the highest levels of quality and compliance for medical applications.

Characteristics:

| Specification | Details |

| Material | Medical-grade silicone or thermoplastic elastomers (TPE) |

| Manufacturing Process | Precision molding, injection molding, and extrusion |

| Customization | Custom sizes, lengths, and designs available |

| Sample | Available upon request |

| Certifications | ISO 13485, FDA |

| Compliance | Biocompatible, safe for medical use |

| Tolerances | ±0.1 mm (or custom per customer specifications) |

| Packaging | Sterile packaging options available |

| MOQ | Minimum order quantity based on customer requirements |

| Lead Time | 15-30 days depending on order size and customization |

| Testing | Quality control checks, including durability, biocompatibility, and functional testing |

Benefits of Our Products:

- Biocompatible Materials

- Precision Manufacturing

- Customizable Design

- Sterile and Safe Packaging

One-stop Service:

Our one-stop service for Custom Medical Grade Stomach Tubes for Emergency Surgical Applications includes complete support from initial design and material selection to final production and delivery. We provide OEM solutions, offering custom sizing, packaging, and features tailored to meet specific medical requirements. Our team handles prototyping, testing, and ensures compliance with ISO 13485 and FDA standards, ensuring high-quality, safe products. From production to timely shipping, we manage every step to guarantee a seamless, efficient experience for our clients.

Quality Assurance:

Our quality assurance for Custom Medical Grade Stomach Tubes for Emergency Surgical Applications is built on rigorous testing and compliance with industry standards. We are certified to ISO 13485 and FDA regulations, ensuring all products meet the highest safety and performance criteria. Our quality control process includes comprehensive testing using advanced equipment, such as coordinate measuring machines (CMM), hardness testers, and biocompatibility testing systems. Each product undergoes thorough inspection for durability, precision, and compliance with medical-grade requirements, guaranteeing reliability and safety in critical applications.

Factory Show:

Our state-of-the-art manufacturing facility is equipped with advanced technologies, including CNC machining centers, mirror EDM, conventional EDM, and high-precision wire cutting machinery, enabling us to achieve exceptional mold precision, consistency, and repeatability. The production floor features 15 rubber compression molding presses and 2 liquid silicone rubber (LSR) injection molding machines, allowing us to efficiently handle both high-volume orders and complex, custom projects. Quality assurance is at the heart of our operations, with strict inspection protocols enforced by a team of experienced quality control specialists using advanced tools such as 3D projectors, sealing integrity testers, durometers, and elasticity gauges. As an ISO 9001 and IATF 16949 certified facility, we meet the highest international standards for product quality, safety, and reliability. To further optimize manufacturing efficiency and maintain product consistency, we have integrated automated systems such as AutoDryers, high-speed doming machines, and precision die-cutting equipment. Additionally, our cleanroom environment ensures the highest level of cleanliness and contamination control, safeguarding the integrity of every product throughout the production process.