Description:

The silicone shower head is an essential accessory for any shower, available in various shapes such as round, square, and single nozzles. Commonly referred to as silicone replacement spray nozzles, rainfall showerheads, and faucet gaskets, these nozzles offer versatility and convenience.

Made from food-grade silicone, our soft shower nozzles are designed to be clog-resistant and require minimal maintenance, typically just a simple wipe to remove limescale buildup. They can withstand temperatures ranging from 0 to 90 degrees Celsius without deformation and are compatible with water pH levels between 5 and 9.

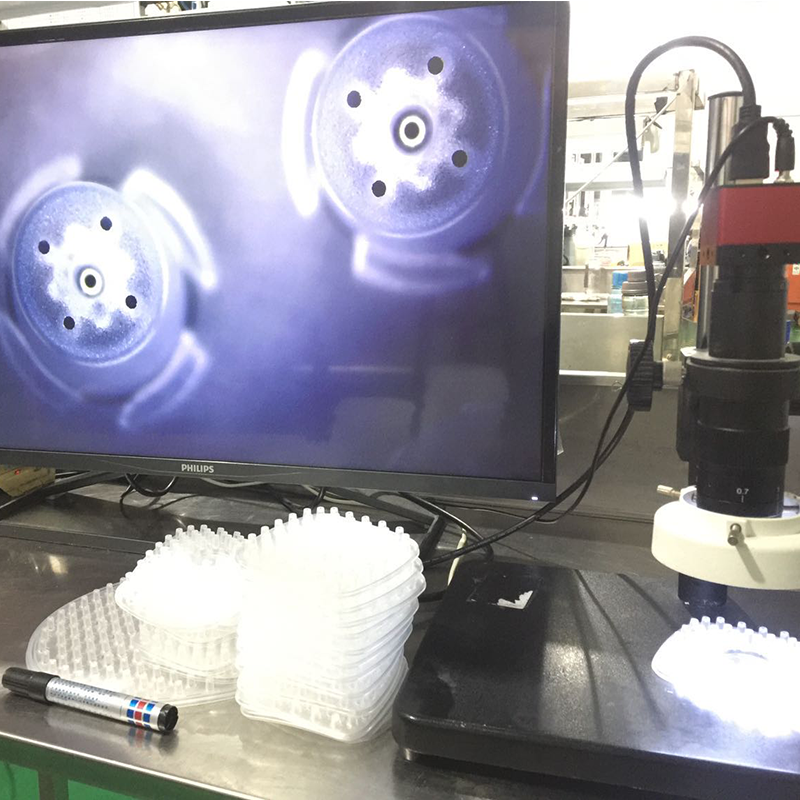

Manufactured using advanced techniques, including precision compression molding and quality control measures, our silicone shower heads ensure durability and performance, making them a reliable choice for any bathroom.

Features:

| Service Specifications | Details |

| Service | OEM |

| Part Material | Silicone or rubber (NR, NBR, SBR, BR, IR, CR, EPDM, IIR, FKM, SIR, PU, ACM, CO, etc.) |

| Material Hardness | Silicone: 20–90 Shore A; Rubber: 20–90 Shore A |

| Color | Customized according to Pantone colors |

| Appearance | As per customer requirements |

| Drawings | Acceptable in 2D or 3D formats |

| Temperature Resistance | 0–90 degrees Celsius |

| Tolerance | ±0.05 mm |

| Technology | Hot compression molding or injection molding |

| Quality Control | Internal QC control |

| Food Grade Material | FDA or LFGB compliant |

| MOQ | Small orders accepted |

| Package | Customized per customer request |

| Trade Terms | Ex-works; FOB Xiamen; CIF |

| Payment Terms | Sample mold: 100% prepaid; MP Mould: 50% deposit via T/T in advance, balance 50% after sample approval |

| Specifications | Compliant with ISO 9001 and ROHS Directive for Green Products |

Production Process:

- Design and Engineering: The process begins with the development of detailed designs and specifications using advanced CAD software. Engineers create 2D and 3D models to ensure precise dimensions and functionality.

- Material Selection: High-quality food-grade silicone is chosen for its durability and resistance to temperature and chemicals, ensuring the final product meets industry standards.

- Molding Process: The selected silicone is subjected to hot compression molding or injection molding, depending on the design requirements. This step involves heating the silicone and placing it into molds to shape the nozzle.

- Curing: After molding, the silicone is cured to enhance its strength and stability. This process typically involves heating the molded parts in an oven to achieve the desired hardness.

- Finishing and Quality Control: The nozzles undergo finishing processes, such as trimming and surface smoothing. Each product is then subjected to rigorous quality control checks to ensure compliance with specifications and performance standards.

- Testing: Functional testing is performed to assess the nozzle’s performance, including water flow and leak resistance. This step ensures that the product meets all operational requirements.

- Packaging: Finally, the silicone gasket shower nozzles are packaged according to customer specifications, ensuring safe transport and delivery.

Quality Test Process:

The quality control process for the Silicone gasket shower nozzle utilizes advanced equipment to ensure the highest standards of quality. Key tools include a Coordinate Measuring Machine (CMM) for precise dimensional checks, an Optical Comparator for profile inspections, and a Durometer to measure material hardness. Leak testing equipment verifies the integrity of seals, while a Water Flow Test Apparatus assesses performance under operational conditions. Additionally, a Temperature and Humidity Chamber simulates various environments to evaluate durability. Trained personnel conduct visual inspections to check for surface defects and color consistency. This comprehensive approach guarantees that each nozzle meets stringent functional and aesthetic requirements.

Why Choose Us?

- Competitive Pricing from the Original Manufacturer: Benefit from cost-effective solutions directly from the source, ensuring excellent value.

- Experienced Team: Our team includes five skilled R&D engineers, seasoned production workers, and dedicated quality control personnel, all committed to delivering high-quality products.

- Efficient Molding Facilities: Our state-of-the-art molding plants enable us to produce tooling with short lead times, allowing for prompt delivery of qualified samples and products.

- Dust-Free Silicone Rubber Manufacturing: We operate in a controlled, dust-free environment to maintain the highest cleanliness standards in silicone rubber production.

- Eco-Friendly Materials: We utilize environmentally friendly materials that comply with ROHS, SGS, ISO, FDA, and LFGB certifications, ensuring safe and sustainable products.

- Comprehensive OEM Services: We offer tailored OEM services to meet your specific design and production requirements, providing flexibility and customization for your unique needs.