Overview

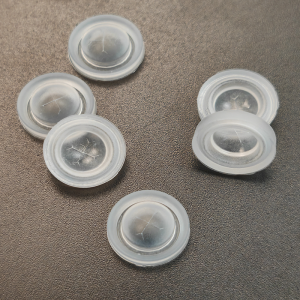

Designed for precision, leak-free dispensing of ketchup, sauces, condiments, and other viscous liquids, our bespoke one-way silicone check valves combine food-grade material safety with engineered slit geometry to deliver reliable “one squeeze — one dispense” performance. Manufactured using advanced LSR injection molding or silicone compression molding depending on volume and design, these valves are fully OEM-customizable (size, slit profile, hardness, color, and packaging) and are produced in an ISO-controlled environment to meet LFGB/FDA food-contact requirements.

![]()

Key Specifications

| Attribute | Specification |

|---|---|

| Material | Platinum-cured food-grade silicone (LSR or compression silicone) — LFGB & FDA compliant |

| Standard Diameters | 9.6 mm, 13.5 mm, 18 mm (custom diameters available) |

| Valve Type | One-way check valve — cross-slit (X-cut) standard; Y-cut, single slit, or custom geometries available |

| Hardness (Shore A) | 30 – 40 A (typical condiment range 35–60 A) |

| Temperature Range | −40 °C to +230 °C (typical); short-term exposure up to +250 °C depending on compound |

| Typical Life | ≥ 200k actuations (application dependent) |

| Leak Rating | Configurable inverted leak test: 24–168 hrs (customer spec) |

| Dimensional Tolerance | ±0.05 mm (critical features ±0.02 mm) |

| Surface Finish | Smooth internal flow path; external matte/gloss options |

| Manufacturing | LSR injection molding (high precision) or silicone compression molding (cost-effective for certain tooling) |

| Certifications | LFGB, FDA (material); produced in ISO 9001 facility |

| Packaging | Bulk, blister, tray, or customer-branded packaging with batch traceability |

| Sample Lead Time | 5–10 business days |

| Production Lead Time | 15–30 business days after sample/tool approval |

| MOQ | Small MOQ accepted for validation; scalable to high volumes |

Core Benefits

- Food-safe, regulation-compliant silicone suitable for direct contact with condiments.

- Tunable flow characteristics via slit geometry and Shore hardness optimization.

- Robust sealing and inverted-leak performance for drip-free dispensing.

- Scalable OEM production: from small validation runs to high-volume automated lines.

Manufacturing & Process Flow

- Material qualification — select platinum-cured LSR or specially compounded compression silicone validated to LFGB/FDA.

- Tooling & mold production — CNC machining, mirror EDM, and slow-speed wire EDM produce high-precision cavities; mold polishing optimizes part release and internal finish.

- Molding — high-precision LSR injection molding with vacuum de-airing and controlled cure cycles for consistent parts; compression molding available for select designs or secondary operations.

- Post-processing — automated flash trimming, visual/vision inspection, and silicone passivation (if required).

- Testing & packing — dimensional inspection, hardness testing, and leak integrity tests; parts packed per specification with full lot traceability.

Quality Assurance & Test Capabilities

Produced under an ISO-9001 quality system, each lot undergoes incoming raw material verification, in-process monitoring, and final QA. Typical equipment and checks include:

- CMM for dimensional verification

- Shore A durometers

- Tensile/elongation testers

- Inverted leak/seal integrity testers (24–168 hrs)

- 3D optical projectors and vision systems for geometry inspection

- Thermal cycling chambers for temperature stability

Third-party LFGB/FDA material verification is available on request.

Typical Applications

- Retail squeeze bottles for ketchup, mustard, mayonnaise, and sauces

- Foodservice and catering dispensers

- Refillable condiment caps and closures

- Specialty viscous product dispensing (sauces, dressings, condiments)

Factory Capabilities & Support

At our advanced manufacturing facility, we integrate cutting-edge technologies—including CNC machining, mirror EDM, conventional EDM, and high-precision slow-speed wire cutting—to achieve unparalleled accuracy in mold fabrication. Our production capacity is powered by 15 rubber compression molding presses and 2 LSR injection molding machines, enabling both high efficiency and flexible output. To ensure uncompromising quality, we employ state-of-the-art inspection systems such as 3D projectors, sealing testers, durometers, and elasticity testers, operated by a certified QA team under ISO 9001 and IATF 16949 standards. Further supported by automated solutions including AutoDryers, high-speed doming machines, and precision die-cutting equipment, our streamlined workflow delivers superior product performance, tight-tolerance consistency, and exceptional reliability across every stage of production.

If you’d like samples, a DFM review, or a quote tuned to your bottle geometry and target viscosity, send your valve size, target dispense force, and expected product viscosity — we’ll provide a detailed recommendation and prototype plan.