Overview

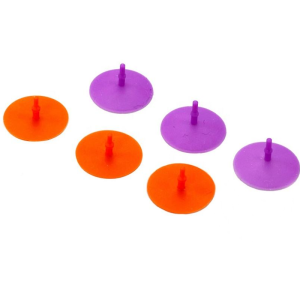

Our Custom Silicone Rubber Injection Molding Umbrella Valves are precision-engineered, one-way sealing solutions designed for leak-proof and drip-free dispensing in condiment bottles and food packaging. Utilizing advanced Liquid Silicone Rubber (LSR) injection molding, these valves ensure superior consistency, durability, and reliable performance for sauces, syrups, and other viscous liquids. We offer comprehensive OEM services, tailoring valve dimensions, slit design, and material properties to meet your specific functional and integration requirements.

![]()

Basic Information

| Attribute | Details |

|---|---|

| Material | Food-Grade Liquid Silicone Rubber (LSR) |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Type | Umbrella / Duckbill Valve |

| Color | Standard (Translucent, White) or Custom |

| Hardness (Shore A) | Customizable (Typically 30-50) |

| Temperature Range | –50°C to +230°C |

| Certifications | FDA, LFGB, ROHS Compliant Materials |

| Molding Process | Precision LSR Injection Molding |

| OEM/ODM | Available |

| MOQ | Negotiable, Small Orders Welcome |

| Sample | Prototypes and Production Samples Provided |

Benefits of Our Products

-

Precision LSR Injection Molding: Ensures high-volume production of flash-free, dimensionally stable valves with exceptional consistency and intricate detail.

-

Reliable Leak-Proof Performance: The umbrella design provides a positive one-way seal, preventing backflow, drips, and contamination for a clean dispensing experience.

-

Superior Material Properties: Offers excellent chemical resistance, long-term flexibility, and stability across extreme temperatures without compromising performance.

-

Fully Customizable Design: Every aspect, from stem diameter and skirt profile to slit configuration and opening pressure, can be engineered to optimize flow for your specific application.

Quality Assurance

Our quality assurance for silicone umbrella valves is built on a foundation of precision manufacturing and rigorous functional testing. We employ certified FDA-compliant LSR materials and maintain strict process control within our ISO 9001-certified system. Each production batch undergoes comprehensive inspection, including dimensional verification with optical measuring systems, durometer hardness testing, and critical functional tests such as cycle life testing (10,000+ actuations), leak-proof pressure testing, and flow rate validation to ensure consistent, reliable performance in your condiment bottles.

Why Partner with Us for Your Manufacturing Needs?

-

Specialized Expertise in Dispensing Valves: With deep technical knowledge in silicone valve design for food packaging, we provide engineered solutions that address critical challenges like sealing, flow control, and user experience.

-

End-to-End Customization & Engineering Support: We offer complete OEM/ODM services, from initial concept and DFM analysis to material selection and production, ensuring the valve is perfectly tailored to your bottle and product.

-

Efficient, Scalable LSR Production: Our dedicated, automated LSR injection molding lines and multi-cavity mold expertise enable high-efficiency manufacturing, ensuring reliable scalability from prototype to high-volume orders.

-

Commitment to Certified Quality & Consistency: Our integrated quality management system, from raw material certification to 100% functional testing, guarantees that you receive a high-performance, safe, and durable component with every order.

Factory Show

Our state-of-the-art manufacturing facility is equipped with dedicated, cleanroom-compatible LSR injection molding machines designed for the high-precision production of silicone umbrella valves. Our in-house mold shop, featuring CNC machining and wire EDM, ensures rapid prototyping and the creation of durable, multi-cavity production molds. On the production floor, quality is monitored in real-time with automated vision inspection systems and dedicated valve testers for seal integrity and actuation force. This vertically integrated, ISO 9001-controlled environment guarantees exceptional product consistency, rapid turnaround, and total supply chain reliability for your critical condiment valve components.