Overview

Our Customized Overmolding ABS + Silicone Head Nozzles for Water-Saving Bathroom Applications deliver durable, comfortable, and water-efficient spray performance for showerheads, faucets, and hand-held sprayers. Engineered with a rigid ABS structural core overmolded with soft, anti-slip silicone skirts or nozzle faces, these nozzles combine precise fluid control (aerators, flow restrictors, multi-jet patterns) with long-lasting corrosion and chlorine resistance. Designed for OEM customization—thread styles, spray patterns, colors, and logos—our overmolded nozzles are optimized for low flow (water-saving) performance without sacrificing user comfort or spray coverage.

![]()

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM / Custom Branding |

| Core Material (substrate) | ABS, PC-ABS, or modified ASA (UV-stabilized) |

| Overmold Material | LSR (liquid silicone rubber) or TPE (medical/food-grade options available) |

| Typical Nozzle Diameters | 6 mm – 30 mm (custom sizes) |

| Spray Types | Aerated stream, rain, mist, multi-jet, adjustable patterns |

| Hardness (Silicone) | Shore A 20–70 (custom) |

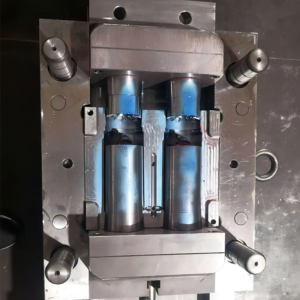

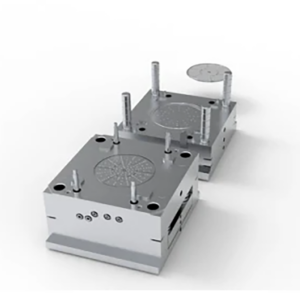

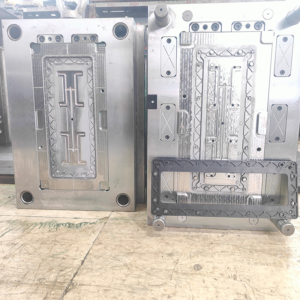

| Molding Process | Insert overmolding / LSR injection over ABS; 2-shot molding as option |

| Surface Finish | Matte, soft-touch, gloss; color matched to Pantone |

| Flow Rates | Configurable: 1.5–9 L/min (per nozzle design & certification) |

| Temperature Range | -40°C to +120°C (depends on material selection) |

| Certifications | ISO 9001, RoHS, REACH (as required) |

| MOQ | Flexible; small pilot runs accepted |

| Sample Lead Time | 5–10 days |

| Production Lead Time | 15–30 days (tooling dependent) |

| Packaging | Custom retail box, bulk cartons, or blister packs |

Key Benefits

- Water-Saving Performance: Integrated flow restrictors and optimized jet geometry reduce water consumption while preserving effective spray coverage.

- User Comfort & Safety: Soft, non-slip silicone faces improve grip and reduce scald risk; silicone resists lime build-up and is easy to clean.

- Durability in Wet Environments: UV-stabilized ABS cores plus LSR/TPE overmolds resist chlorine, detergents, and thermal cycling for long service life.

- OEM Flexibility: Fully customizable thread types, spray patterns, colors, logos, and secondary finishing (chrome plating on ABS, PVD, or paint).

Quality Assurance

We manufacture to an ISO 9001 quality system with full incoming material inspection and in-process controls. Each nozzle family undergoes dimensional verification (CMM/optical), adhesion and peel tests for the overmold bond, flow-rate validation, spray pattern imaging, and accelerated aging (thermal cycling and chlorine exposure). Finished lots receive sampling for mechanical durability, color consistency, and leak/pressure testing. Traceable batch records and test reports are provided for all production runs.

Why Partner With Us?

- Proven Overmolding Expertise — Decades of experience in ABS + silicone insert molding and LSR overmolding for wet-environment applications.

- End-to-End OEM Service — From DFM and rapid prototyping to tooling, validation, and scalable mass production.

- Design for Water Efficiency — Engineering support to meet water-saving targets (flow specs, aerator sizing, and regulatory guidance).

- Robust Quality & Compliance — ISO-aligned processes, material traceability, and comprehensive testing to reduce product risk.

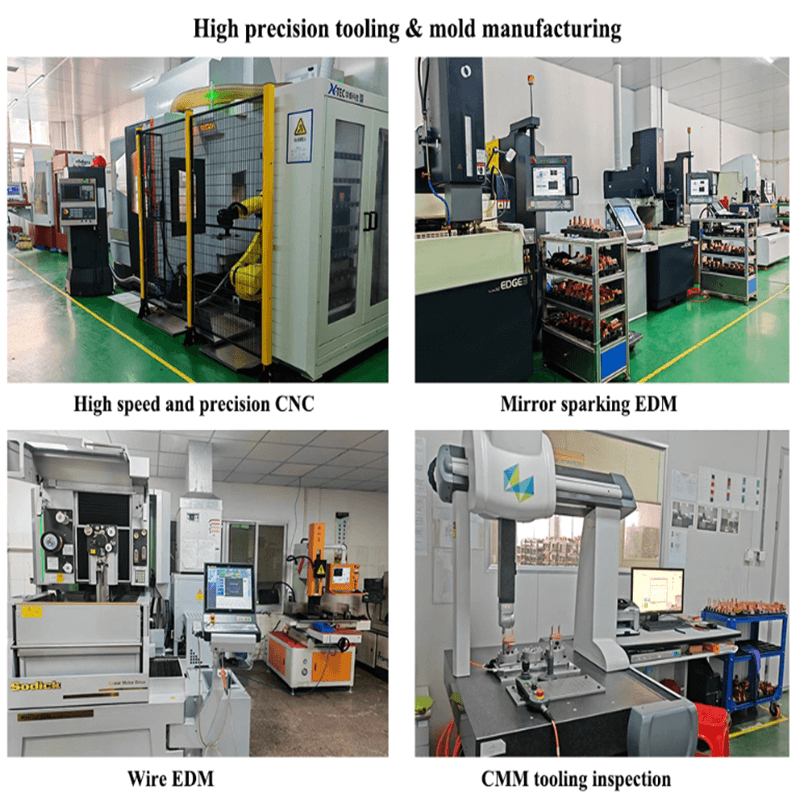

Factory Show

Our facility combines advanced tooling and molding capabilities—multi-axis CNC, mirror EDM, and precision wire-cutting for high-accuracy molds—alongside dedicated LSR injection presses and insert/2-shot molding cells for ABS + silicone assemblies. We operate plating and painting lines (for optional chrome or PVD finishes), ultrasonic cleaning stations, and automated assembly/inspection lines (vision systems for spray pattern checks). Quality labs include CMM, 3D optical projectors, flow/leak rigs, durometers, and environmental chambers to validate chlorine/temperature resistance and long-term performance.