Silicone valves play an integral role in various industries, including food and beverage, healthcare, personal care, and automotive. These valves are designed to prevent backflow and control the flow of air or fluid with high precision and efficiency. When it comes to selecting the appropriate silicone valve for your dispensing system, understanding the types, material specifications, and application requirements is crucial.

At YJCPolymer, a leading manufacturer of high-quality silicone valves, we offer custom solutions tailored to meet the needs of a wide range of industries. With over a decade of experience in manufacturing precision silicone valves using liquid injection molding technology, we specialize in providing one-stop service for all your silicone valve needs.

In this blog, we’ll explore the different types of silicone valves, their applications, and what to consider when choosing the right valve for your dispensing system.

1. Food Grade Silicone Cross Slit Valve

One of the most common types of silicone valves used in the food and beverage industry is the cross slit valve. Made from LFGB-approved food-grade liquid silicone (LSR), these valves are ideal for dispensing a wide variety of liquids, such as ketchup, mayonnaise, salad dressing, honey, and even sports drinks.

Why Choose a Cross Slit Valve?

- Leak-proof design: The cross slit design offers an effective seal that prevents leaks and backflow, even with highly viscous liquids.

- Customizable for different viscosities: These valves can be designed with various slit sizes and thicknesses to suit the specific needs of the liquid being dispensed.

- Durable and reliable: With high-quality food-grade materials, the cross slit valve provides excellent durability, making it a great choice for high-volume production and continuous use.

At YJCPolymer, we specialize in custom manufacturing of food-grade silicone valves to ensure that our products meet the exact requirements of our clients. Whether you need valves for small batches or large-scale production, we offer efficient, cost-effective solutions tailored to your needs.

2. Silicone Duckbill Valve

The duckbill valve is another widely used one-way valve made from elastomeric liquid silicone or solid silicone materials. This valve’s unique duckbill-shaped lip provides a reliable seal that prevents backflow while allowing forward flow, making it ideal for many applications.

Why Choose a Duckbill Valve?

- Seamless one-piece design: The duckbill valve’s design integrates the sealing function into a single elastomeric component, making it easy to assemble and highly effective in preventing backflow.

- Versatile applications: Commonly used in both consumer and industrial applications, this valve is well-suited for handling a variety of fluids, from water to more viscous substances.

- Cost-effective and durable: The simple design of the duckbill valve allows for easy manufacturing, which reduces production costs without compromising on performance.

At YJCPolymer, we manufacture duckbill valves with high precision and custom design options to meet specific requirements, ensuring a perfect fit for your dispensing systems.

3. Silicone Umbrella Valve

The umbrella valve, also known as the mushroom valve, is a two-way valve that allows the flow of fluids in both directions, with controlled pressures. This valve is often used in applications where both vacuum and over-pressure conditions need to be managed.

Why Choose an Umbrella Valve?

- Dual-functionality: The umbrella valve works as a vent and relief valve, allowing air to enter when there’s a vacuum and venting excess pressure when necessary.

- Pressure regulation: The valve helps maintain optimal pressure within containers or systems, preventing damage or degradation of the contents.

- Versatile in application: It’s commonly used in medical, food, and beverage packaging, and even in automotive systems, making it a highly versatile option.

Our high-precision manufacturing process at YJCPolymer ensures that every umbrella valve is made to meet the exact specifications required for reliable performance in demanding environments.

4. Medical Silicone Check Valve

The medical silicone check valve is made from medical-grade silicone materials, which meet ISO10993 bio-compatibility standards. These valves are primarily used in pharmaceutical applications, medical devices, and healthcare systems, where precision, safety, and performance are critical.

Why Choose a Medical Silicone Check Valve?

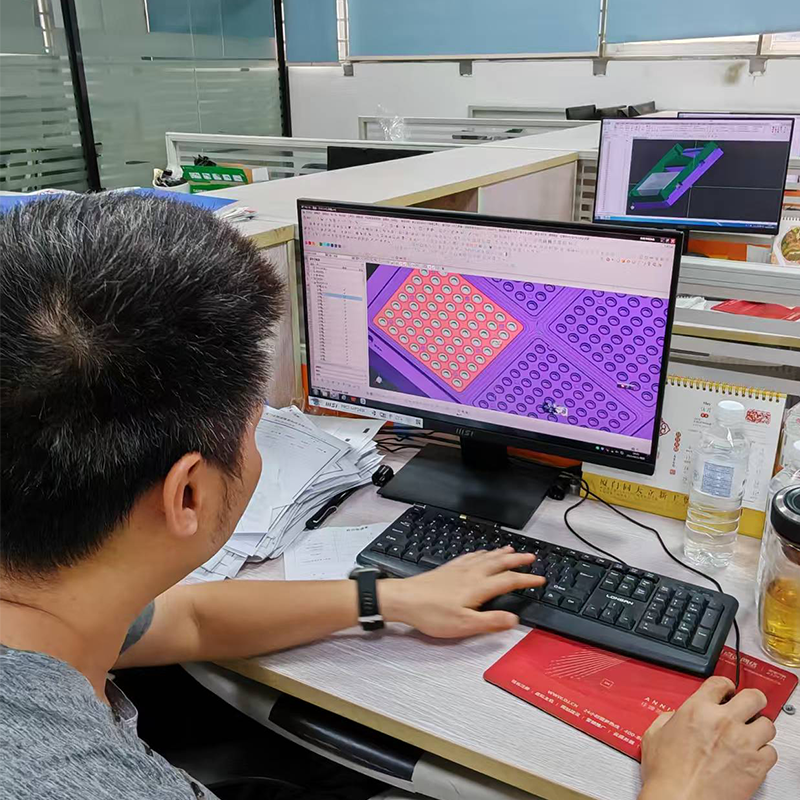

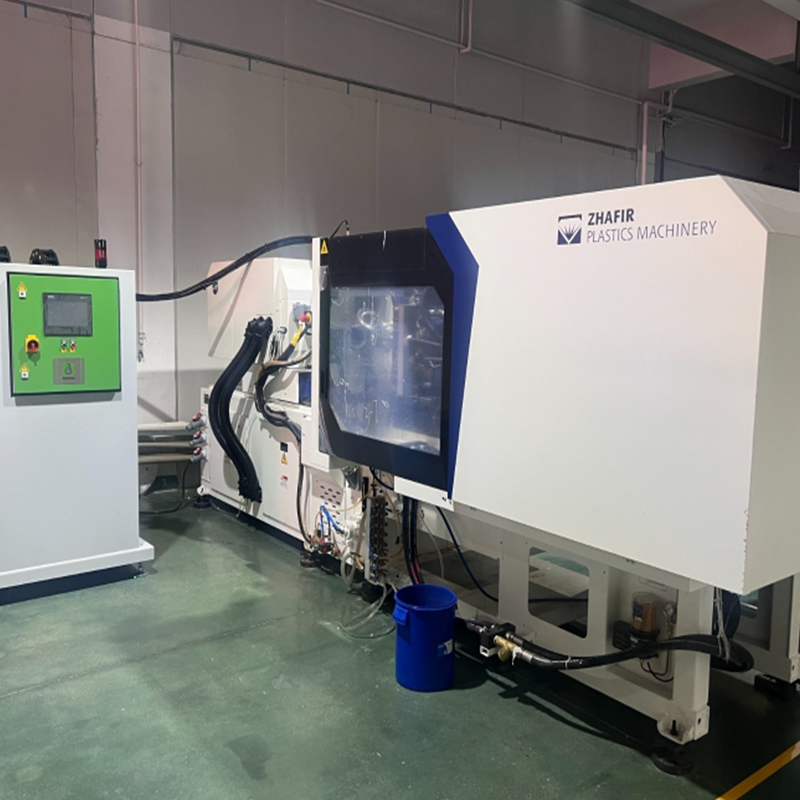

- High precision and accuracy: Medical silicone valves require exact dimensional tolerances, making them more challenging to manufacture. At YJCPolymer, we utilize state-of-the-art LSR injection molding technology and a cleanroom environment to ensure the highest precision and compliance with regulatory standards.

- Bio-compatible materials: Our medical-grade silicone valves pass strict bio-compatibility tests, ensuring safety and reliability in healthcare applications.

- Custom solutions for healthcare: Whether you need valves for drug delivery systems or diagnostic equipment, we offer custom services to meet the unique requirements of medical devices.

As an ISO13485-certified manufacturer, YJCPolymer is committed to providing high-quality, biocompatible silicone valves that meet the rigorous standards of the healthcare industry.

Why Choose YJCPolymer for Your Silicone Valve Needs?

With our extensive experience in liquid silicone rubber (LSR) injection molding, YJCPolymer is the go-to supplier for high-precision silicone valves. Our factory is equipped with advanced automated mass production lines that can handle both small and large-scale orders efficiently. We are proud to offer:

- One-stop service for silicone valve manufacturing, from design to production, and even after-sales support.

- Custom silicone valve solutions tailored to meet your specific requirements, whether for food-grade, medical, industrial, or automotive applications.

- High-quality manufacturing processes and materials that ensure durability, reliability, and optimal performance.

- Competitive pricing and fast delivery times to keep your project on track and within budget.

We understand that selecting the right silicone valve for your dispensing system is crucial for your project’s success. That’s why our team of experienced engineers and technicians is always available to offer customized advice and technical support to ensure that your system operates smoothly and efficiently.

Contact YJCPolymer Today

At YJCPolymer, we’re dedicated to providing high-quality silicone valve solutions that exceed our customers’ expectations. Whether you need food-grade valves, medical-grade valves, or custom silicone valves for other applications, we’ve got you covered.

Ready to get started? Contact us today to learn more about our silicone valves and how we can support your dispensing system. Let us help you choose the perfect valve solution for your needs, and we look forward to partnering with you on your next project!