When it comes to creating high-quality shower nozzle mold tooling, precision, material selection, and manufacturing expertise are key to ensuring durability and flawless performance. At YJCPolymer, we take pride in offering OEM services that provide fully customized solutions to meet the specific needs of our clients. Whether you’re designing a new product or replacing an old mold, understanding the production process for shower nozzle mold tooling is crucial for achieving optimal results.

This blog will delve into the intricate process of producing high-quality shower nozzle mold tooling, covering every step from initial design to final production, while emphasizing the importance of collaboration, DFM (Design for Manufacturability), and selecting the right suppliers. By the end of this post, you’ll have a comprehensive understanding of how YJCPolymer can support you in delivering top-notch shower nozzle products.

The Importance of High-Quality Shower Nozzle Mold Tooling

Shower nozzles are critical components that control water flow and pressure, making them a vital part of shower systems. A high-quality mold tooling is essential to ensure precise shapes, durability, and efficient water flow. The production process for shower nozzle molds involves various stages that require the expertise of specialized manufacturers. This is why OEM services provided by a reputable company like YJCPolymer are vital for producing long-lasting, high-performance molds.

Not only do these molds need to have an excellent aesthetic appearance, but they also have to perform reliably under different water pressures, temperature conditions, and regular wear and tear. The mold tooling process must account for all these factors, ensuring that every nozzle produced is up to the standards required for customer satisfaction.

Step-by-Step Guide to the Production Process of Shower Nozzle Mold Tooling

Creating high-quality shower nozzle mold tooling involves several steps, each of which must be carefully planned and executed. Here’s an overview of the production process:

1. Design and Prototyping

The first stage of the process is design and prototyping. Design for Manufacturability (DFM) plays a pivotal role in this phase. At YJCPolymer, we work closely with our clients to ensure the design is not only aesthetically pleasing but also optimized for mass production. DFM involves considering the following key factors during the design phase:

- Material Selection: Choosing the right material is crucial for the durability and performance of the mold. For shower nozzles, corrosion resistance, temperature tolerance, and smooth water flow are all factors that must be accounted for.

- Tolerances and Dimensions: Shower nozzles require precise dimensions to ensure proper fitting and functionality. The design must meet these tolerances for accurate mold production.

- Ease of Manufacturing: The design must be simple enough for efficient manufacturing but also sophisticated enough to meet the customer’s performance requirements.

Once the design is finalized, prototyping is done using rapid prototyping methods. This allows us to create a physical model of the mold tooling, enabling a closer inspection of fit, form, and function before moving on to full-scale production.

2. Tooling Manufacturing: Precision and Detail

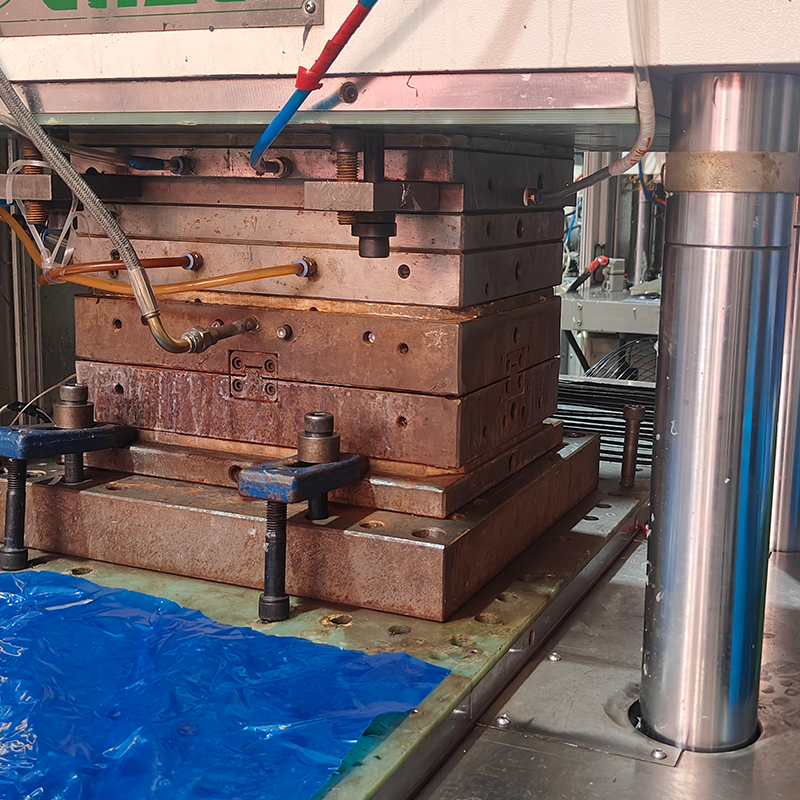

Once the prototype is approved, the next stage is tooling manufacturing. This is where YJCPolymer’s expertise in injection molding, CNC machining, and tooling production truly shines. Tooling is typically made using high-quality steel or alloy metals, chosen for their durability and ability to withstand high pressure and temperature. The tooling process is a critical step, as it will define the quality of every single shower nozzle produced.

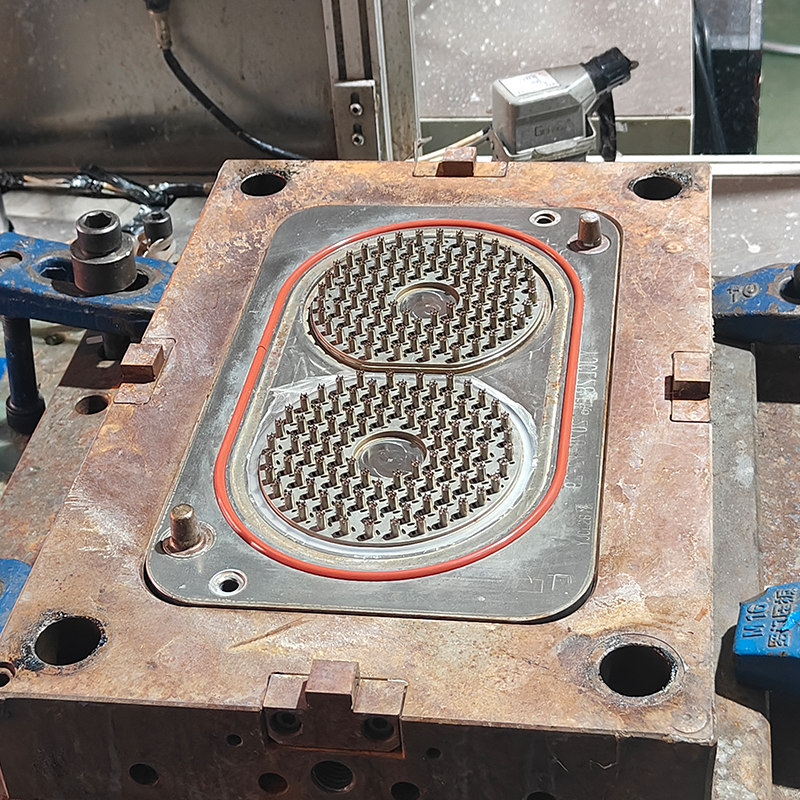

- CNC Machining: Precision CNC machining is used to create the molds with high accuracy. Using computer-controlled machinery ensures that every detail of the mold is perfect and meets the tightest tolerances.

- Surface Finishing: For shower nozzles, a smooth and polished surface is essential for both aesthetic reasons and functionality. The mold tooling must allow for consistent water flow and prevent the build-up of minerals or debris. At YJCPolymer, we use advanced surface treatment techniques such as electroplating and polishing to create a smooth, durable surface that ensures high performance.

- Cooling and Heating Systems: Injection molds for shower nozzles often include advanced cooling and heating channels. These systems are carefully engineered to ensure uniform temperature distribution during the injection process, which is essential for the molding of high-quality parts.

3. Injection Molding and Quality Control

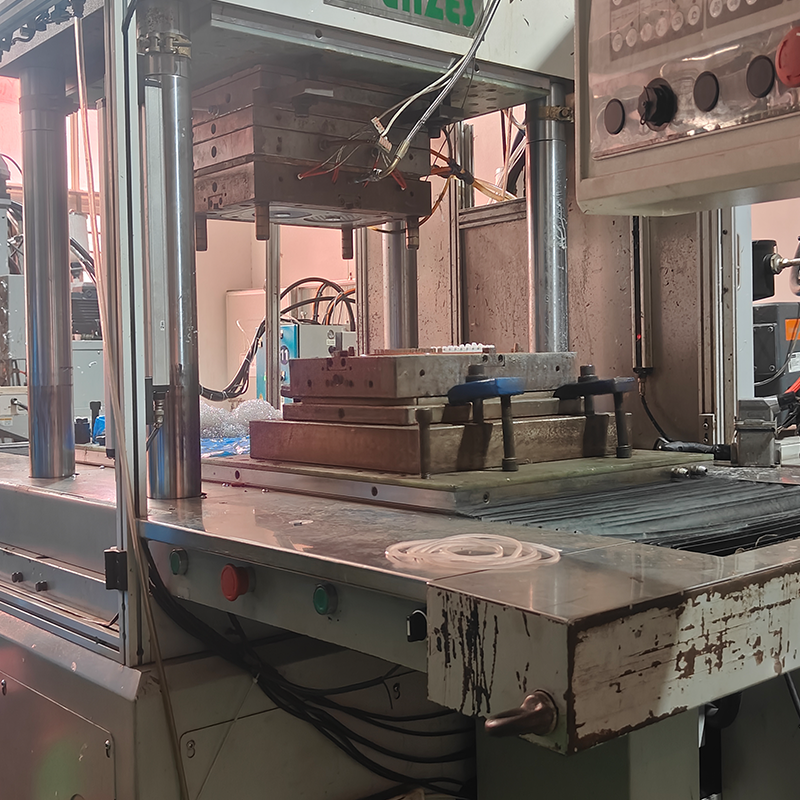

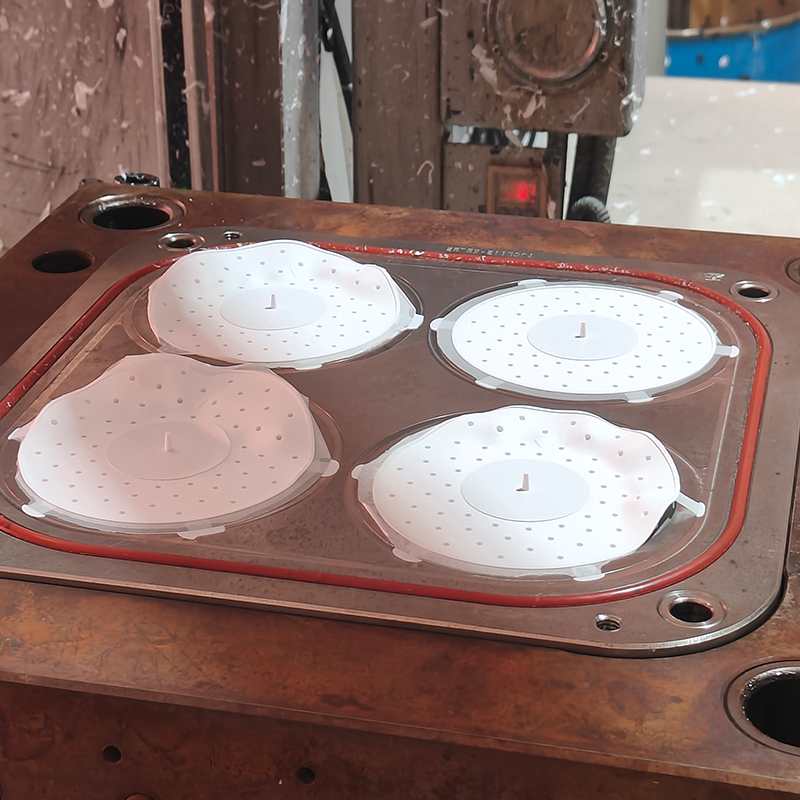

The next step is the actual injection molding process. The mold tooling is placed in an injection molding machine, where raw material—usually a high-grade plastic or metal—is injected into the mold cavity under high pressure. This process produces the final part, which is then ejected from the mold.

At YJCPolymer, we ensure that the injection molding process is carried out with the highest standards of quality control. Our quality assurance team rigorously inspects the molds at every stage, from material handling to post-production, to ensure that the molds meet the customer’s specifications. We monitor critical variables such as:

- Dimensional Accuracy: The size and shape of the nozzle are checked against precise specifications to ensure perfect fitment.

- Surface Quality: The mold’s surface is checked for any imperfections, such as roughness or blemishes, that might affect water flow or aesthetics.

- Strength Testing: Shower nozzles must withstand high-pressure water systems. We test each mold for structural integrity and pressure tolerance.

4. Secondary Operations and Finishing

Once the parts are molded, they often undergo secondary operations. These can include:

- Trimming: Removing any excess material or burrs from the molded part to ensure a smooth, finished look.

- Assembly: In cases where the nozzle is made up of multiple components, the assembly process ensures that everything fits together seamlessly.

- Surface Treatment: Additional coatings or treatments may be applied, such as anti-corrosion coatings, to increase the part’s longevity and resistance to wear.

Each part is inspected and tested again to guarantee it meets the high standards set for it.

5. Packaging and Delivery

The final step in the production process is packaging and delivery. We at YJCPolymer pay careful attention to packaging to ensure that the molds arrive at their destination without damage. The parts are packed securely and shipped according to the agreed-upon timeline.

The Importance of Working with Reliable Suppliers and Manufacturers

Choosing the right suppliers and manufacturers for your shower nozzle mold tooling is crucial. At YJCPolymer, we work with a network of trusted suppliers to source only the best materials for your molds. By partnering with the most reliable suppliers, we ensure that your molds are not only durable but also cost-effective and delivered on time.

We understand that every project is unique, which is why our OEM services are designed to offer flexible, customized solutions. Whether you require small-batch production or high-volume runs, we offer the same level of commitment to excellence, making us your preferred partner in mold tooling production.

Why Choose YJCPolymer for Your Shower Nozzle Mold Tooling?

At YJCPolymer, we specialize in high-quality, precision mold tooling for a wide range of applications. With our years of experience in OEM service, DFM, and high-performance tooling production, we are equipped to handle every aspect of your project—from initial design to final delivery. Our commitment to providing exceptional customer service, top-tier manufacturing processes, and reliable support makes us a trusted partner for your shower nozzle tooling needs.

Contact us today to discuss how our custom mold tooling solutions can help elevate your next project. Our team of experts at YJCPolymer is ready to work with you every step of the way, ensuring that your tooling is optimized for both quality and cost-efficiency.Let us help you create the perfect mold tooling for your shower nozzles, delivering long-lasting performance and functionality that your customers will love.