In the world of materials science, understanding the distinction between thermosets and thermoplastics is crucial for selecting the right material for your manufacturing needs. Whether you’re designing parts for automotive, aerospace, medical, or consumer goods industries, choosing the appropriate polymer can significantly impact performance, cost, and production efficiency. At YJCPolymer, we specialize in both thermoset and thermoplastic materials, offering high-quality manufacturing solutions that cater to your unique requirements.

In this article, we’ll break down the key differences between thermosets and thermoplastics, their properties, advantages, limitations, and real-world applications, guiding you through the best material choices for your projects.

What is Thermoset Plastic?

Thermoset plastics are materials that irreversibly harden when heated, undergoing a chemical reaction that forms a network of cross-linked bonds between polymer chains. Once cured, thermoset plastics cannot be remelted or reformed, making them ideal for applications where stability, heat resistance, and durability are essential.

Common thermoset materials include:

- Epoxy (EP): Known for its excellent adhesion, chemical resistance, and mechanical strength, epoxy is widely used in aerospace, electronics, and adhesives.

- Phenolic (PF): Famous for its heat resistance and flame retardancy, phenolic is ideal for electrical insulation and automotive brake components.

- Polyurethane (PU – thermoset): Often used in rigid foams, coatings, and elastomers for toughness and wear resistance.

- Silicone: Known for its flexibility at extreme temperatures, silicone is commonly used in medical devices, kitchenware, and sealing applications.

- Melamine Formaldehyde (MF): Utilized in laminates, molded tableware, and coatings due to its hardness and stain resistance.

What is Thermoplastic?

Thermoplastics, on the other hand, are polymers that soften when heated and harden upon cooling, with this process being reversible. This unique feature allows thermoplastics to be melted and reshaped multiple times without degrading their chemical structure, making them ideal for high-volume production methods such as injection molding, extrusion, and 3D printing.

Common thermoplastic materials include:

- Polypropylene (PP): Lightweight and fatigue-resistant, commonly used in automotive interiors and medical devices.

- Polyethylene (PE): Chemically resistant and moisture-proof, used in piping, containers, and plastic films.

- Polystyrene (PS): Rigid and cost-effective, found in disposable packaging and insulation.

- Polycarbonate (PC): Known for its high-impact resistance and transparency, used in eyewear lenses and bulletproof glass.

- Acrylic (PMMA): Transparent and UV-resistant, used in signage and displays.

Key Differences Between Thermoset and Thermoplastic Materials

While both thermosets and thermoplastics have their place in modern manufacturing, their differences are substantial and impact their applications, performance, and cost-effectiveness. Let’s dive deeper into how these materials compare:

| Property | Thermoset Plastics | Thermoplastic Plastics |

|---|---|---|

| Heat Deflection Temperature | Very high; excellent dimensional stability under heat | Moderate to high; may deform under prolonged heat |

| Wear Resistance | High; resistant to friction and surface degradation | Moderate; varies by type (e.g., nylon is good, ABS less so) |

| Chemical Resistance | Outstanding; highly resistant to solvents, acids, and fuels | Varies; good in PE, PP, PTFE, but poor in others like ABS or PC |

| Elasticity | Low; rigid and brittle under tension or flex | High; flexible and stretchable depending on the polymer |

| Density | Generally higher due to cross-linked structure | Typically lower; lightweight and design-flexible |

| Toughness | Low to moderate; brittle under impact | High; absorbs energy well, ideal for shock loading |

| Heat Reusability | Not reusable; cannot be reshaped after curing | Reusable and recyclable; can be re-melted repeatedly |

| Processing | Requires curing; longer cycle times and complex tooling | Fast and efficient; supports injection, extrusion, thermoforming |

| Cost | Higher; longer tooling setup and waste cannot be reused | Lower; fast cycle time, regrindable scrap, ideal for high-volume production |

Thermoset Plastics Advantages

Thermoset plastics offer several distinct advantages, particularly in high-performance environments:

- Exceptional Heat Resistance: Thermosets maintain structural integrity at high temperatures, making them ideal for applications such as automotive engine parts, aerospace components, and electrical insulation.

- Outstanding Chemical Resistance: These materials are highly resistant to degradation from solvents, acids, alkalis, and fuels, which is crucial for chemical processing and aerospace applications.

- Dimensional Stability: Once cured, thermosets do not shrink or warp, ensuring tight tolerances are maintained in parts like electrical connectors and mechanical housings.

- Electrical Insulation: Thermoset plastics, like epoxy and phenolic, offer excellent dielectric properties, which is why they are often used in circuit boards, electrical insulators, and switches.

- Long-Term Durability: These materials exhibit excellent resistance to fatigue and aging, making them ideal for parts that must endure long-term exposure to vibration or environmental stress.

Thermoplastic Plastics Advantages

Thermoplastics are extremely versatile and offer numerous benefits, especially for high-volume production runs:

- Flexible Processing: Thermoplastics can be processed using high-speed methods like injection molding, blow molding, and 3D printing, making them highly efficient and cost-effective for large-scale manufacturing.

- Impact Toughness: Thermoplastics such as ABS and polycarbonate are highly impact-resistant and flexible, making them suitable for applications like automotive bumpers and drop-resistant housings.

- Lightweight and Low-Density: Most thermoplastics are lighter than thermosets and metals, providing advantages in industries like automotive and transportation where weight reduction is critical.

- Recyclability and Reusability: Unlike thermosets, thermoplastics can be reheated and reshaped, making them ideal for recycling and sustainable manufacturing practices.

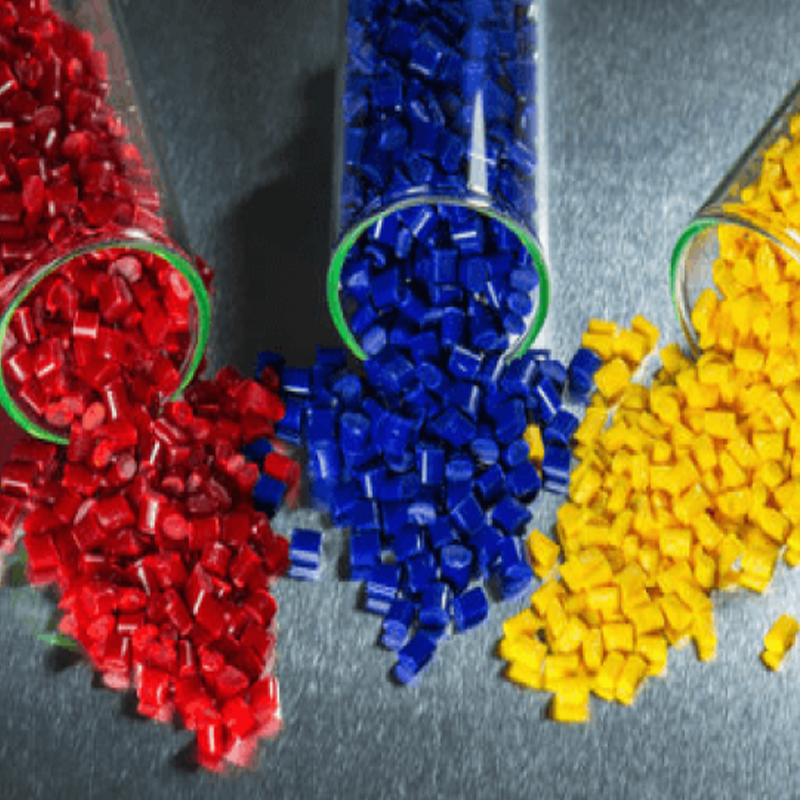

- Aesthetic Versatility: Thermoplastics offer a wide range of finishes and colors, making them ideal for consumer goods, electronics, and medical devices where aesthetics are important.

Application Differences: Thermosets vs. Thermoplastics

Both thermosets and thermoplastics are used across a wide range of industries. However, their characteristics make them more suitable for specific applications:

Thermoset Plastics Applications:

- Aerospace Components: Used in composite structures, high-performance adhesives, and radomes due to their strength and heat resistance.

- Automotive Parts: Ideal for under-the-hood components such as valve covers and ignition systems where heat and chemical exposure are critical.

- Electrical Insulation: Commonly found in printed circuit boards (PCBs), switches, and transformers.

- Structural Adhesives & Sealants: Epoxies and polyurethanes are used in high-strength bonding for aerospace and industrial applications.

Thermoplastic Plastics Applications:

- Consumer Goods & Packaging: Found in everyday items like food containers, bottles, toys, and household goods due to their low cost and flexibility.

- Automotive Interiors & Exteriors: Used for bumpers, dashboards, door panels, and light housings, where impact resistance and design flexibility are essential.

- Medical Devices: Transparent and sterilizable thermoplastics like PC and PMMA are used in syringes, IV bags, and diagnostic equipment.

- Construction Materials: PVC and HDPE are used for pipes, window frames, and roofing membranes due to their durability and ease of installation.

Why Choose YJCPolymer for Your Thermoset and Thermoplastic Needs?

At YJCPolymer, we offer high-quality OEM services and one-stop manufacturing solutions for both thermoset and thermoplastic materials. With extensive expertise in both material types, we can provide the right solution for your unique production needs, ensuring optimal performance and cost-efficiency. Whether you are looking for durable thermoset materials for high-temperature applications or versatile thermoplastics for mass production, our team can help you choose the best material and manufacturing process for your project.

Our high-quality manufacturing processes and custom services ensure that every part meets stringent quality standards. With our years of experience and a commitment to innovation, we’re your trusted partner in delivering cost-effective, reliable, and high-performance solutions for any industry.

Ready to take your manufacturing to the next level? Contact YJCPolymer today to learn more about how our OEM services and custom solutions can meet your needs!