The demand for precision and miniaturization in the medical device industry is growing rapidly. As technology advances, medical devices like pump catheters, micro valves, and other miniature components are becoming more intricate and specialized. To meet these needs, YJCPolymer is leveraging cutting-edge Micro Molding and Dual-Component Silicone Injection Molding technologies to manufacture ultra-small, highly functional parts that meet the rigorous standards of modern healthcare applications.

In this blog, we will explore the unique advantages of Micro Molding technology, its application in medical devices such as pump catheters and micro valves, and how dual-component silicone injection molding plays a crucial role in ensuring performance, durability, and efficiency in these critical parts.

What Is Micro Molding Technology?

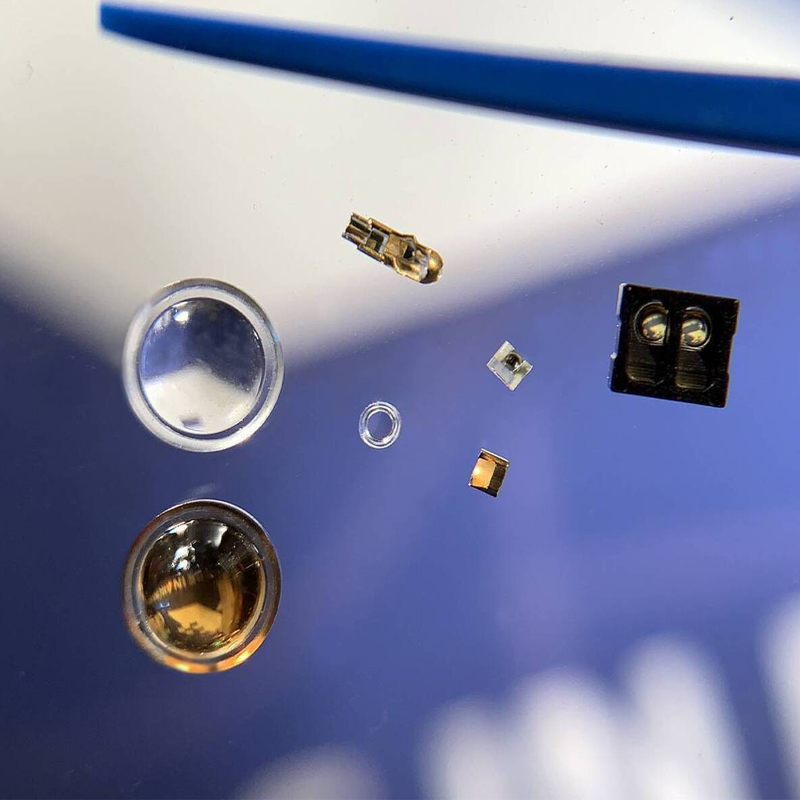

Micro Molding is a highly specialized manufacturing process used to produce tiny components with extremely fine details, typically in the range of millimeters or micrometers. This process is ideal for applications that demand extreme precision and high-volume production. At YJCPolymer, we use state-of-the-art micro injection molding machines that enable the fabrication of parts with complex geometries, precise dimensions, and tight tolerances—essential for applications in industries like healthcare, automotive, and electronics.

In the medical field, micro molding has become indispensable for the production of pump catheters, micro valves, and other medical components. These parts are often required to function within tight specifications, which makes traditional manufacturing methods inadequate for such small-scale applications. Micro molding allows for the creation of small, intricate parts that maintain high levels of performance, such as pump catheters that deliver medication efficiently or micro valves that regulate fluid flow in delicate systems.

Key Advantages of Micro Molding in Medical Applications

- Precision and Accuracy:

Micro molding excels in creating parts with fine details and tight tolerances. The accuracy of the process ensures that the resulting components meet the exact specifications required for medical applications. For instance, pump catheters require precise diameters to ensure proper fluid delivery, while micro valves need to have exact sealing capabilities to function properly without leakage. - Material Optimization:

Micro molding allows for better control over the amount of material used, minimizing waste and reducing production costs. Additionally, the use of high-performance materials like medical-grade silicones or thermoplastics ensures the longevity, biocompatibility, and chemical resistance of the components. - Complex Geometries:

The micro molding process allows for the creation of highly complex, detailed designs that are not possible with traditional manufacturing methods. Whether it’s a tiny valve with multiple moving parts or a catheter designed to fit into tight spaces within the body, micro molding can achieve intricate designs that ensure functionality without compromising on space or usability. - Scalability:

Micro molding is ideal for high-volume production, making it an efficient choice for manufacturers producing large quantities of medical devices. With automated processes, YJCPolymer can deliver rapid production timelines, ensuring that you can meet tight deadlines and large order quantities. - Enhanced Consistency and Quality:

Micro molding ensures consistency across large production runs. Each part is created with the same level of precision, ensuring uniformity and reliability. This is critical in medical devices where the quality of each individual component can impact the overall performance of the device.

Dual-Component Silicone Injection Molding: A Perfect Fit for Medical Device Manufacturing

Dual-component silicone injection molding is a versatile and highly effective process used to combine two different types of silicone material—each with different properties—into a single, cohesive part. This process is especially beneficial in medical applications where components need multiple functional attributes in one product. The ability to combine two different materials allows manufacturers to optimize performance, improve durability, and ensure ease of use in devices such as pump catheters and micro valves.

For example, pump catheters need a soft, flexible outer layer to make insertion into the body easy, yet they require a firm, durable inner layer to maintain structural integrity under pressure. By combining these two silicone materials in a single molding process, YJCPolymer ensures that each catheter is both functional and comfortable for patients.

The Role of Dual-Component Molding in Micro Valves

Micro valves, another essential component in modern medical devices, require precision in design and material properties. In fluid regulation applications, it’s essential that the valve seals perfectly and opens/closes with high accuracy. By using dual-component molding, we can use one material for the valve seat (for durability and strength) and another material for the sealing surface (for flexibility and precise sealing). This combination of materials improves the performance of the valve and ensures a higher level of control over the fluid flow, which is especially important in applications such as infusion systems and drug delivery pumps.

Manufacturing Process at YJCPolymer

At YJCPolymer, we follow a streamlined process to ensure the highest quality and precision in every part we manufacture. Our state-of-the-art facilities are equipped with high-precision injection molding machines designed specifically for micro molding and dual-component molding. Here’s a closer look at our process:

- Design Consultation and Prototyping:

We work closely with our clients from the initial design phase to ensure the part meets all technical specifications. Using CAD and CAM software, we create prototypes to validate the form, fit, and function of the components before starting full production. - Material Selection:

Based on the application, we assist in choosing the right material—whether it’s medical-grade silicone, thermoplastics, or other engineered materials. We ensure that the materials used are biocompatible, durable, and meet all industry standards. - Precision Manufacturing:

Our dual-component molding process allows for the combination of two silicone materials, ensuring that the components meet the required performance characteristics. Our equipment is capable of handling both low-volume prototyping and high-volume production, offering flexibility for various project scales. - Quality Control:

At YJCPolymer, quality is our top priority. We perform rigorous testing on every component, including dimensional inspection, functional testing, and biocompatibility testing. Our process is compliant with ISO 9001 and ISO 13485 standards, ensuring that every part we manufacture meets the highest standards for medical device production. - Packaging and Delivery:

After manufacturing, each component undergoes thorough inspection before being packaged according to your specifications. Whether you need sterile packaging or custom labeling, we can handle it. Our advanced logistics system ensures timely delivery to meet your project deadlines.

The Future of Micro Molding and Dual-Component Molding in Medical Devices

As medical devices continue to evolve toward smaller, more complex designs, the need for advanced manufacturing techniques like micro molding and dual-component molding will only increase. YJCPolymer is committed to staying at the forefront of this technology, offering custom solutions that meet the specific demands of our clients.

Ready to Bring Your Medical Device Designs to Life?

If you’re working on a new medical device project, whether it’s a pump catheter, micro valve, or any other miniature component, YJCPolymer is here to help. Our micro molding and dual-component silicone injection molding capabilities can help you create precision parts that meet your exact specifications. Contact us today to discuss your project, and let’s collaborate to bring your design to life with the performance and quality it deserves.