Description:

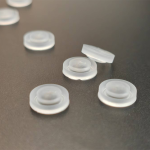

Our 33 mm No-Leak One Way Squeeze Bottle Valves are precision-engineered for clean, consistent ketchup and sauce dispensing. Manufactured from FDA- and LFGB-compliant, platinum-cured food-grade silicone, these valves are produced using liquid silicone rubber (LSR) injection molding and precision cross-slit cutting. The one-way check design ensures effortless squeeze-to-dispense action while preventing drips, leaks, and air backflow—delivering a superior consumer experience with every use. With excellent thermal stability (–40 °F to 450 °F), high elasticity, and long-term durability, these valves are ideal for ketchup, condiments, syrups, and other viscous liquids.

As an OEM manufacturer, we provide end-to-end customization—from slit geometry, hardness, and flow rate to diameter sizing and bottle cap integration—ensuring your packaging solution is fully optimized for brand performance and consumer convenience.

Basic Information:

- Place of Origin: Xiamen, China

- Size: 33 mm diameter (customizable)

- Shape: Round, cross-slit (other geometries available)

- Brand Name: OEM / Custom Branding

- MOQ: Small orders accepted

- Material: Food-grade platinum-cured LSR silicone

- Logo: Custom logo and cap branding available

- Certifications: ISO 9001, IATF 16949, FDA, LFGB, RoHS

- Packaging: Tailored hygienic packaging solutions

- OEM Services: Fully supported

- Primary Use: Ketchup, sauces, syrups, viscous liquid dispensing valves

- Sample Lead Time: 5–7 business days

- Production Lead Time: 20–25 business days

Key Benefits:

- Leak-proof one-way check valve for ketchup and condiment bottles

- Cross-slit design delivers smooth, controlled dispensing with one squeeze

- ±15° dispensing angle accuracy for precise flow performance

- 7 days × 24 hours inverted leak-proof testing ensures reliability

- Non-stick silicone prevents residue buildup and clogging

- Heat- and cold-resistant (–40 °F to 450 °F) for wide application environments

- Automated production line capacity of 200,000 pcs/day

- Free samples available for quality validation

Quality Assurance:

Every valve undergoes rigorous quality checks to ensure sealing integrity, elasticity, and food safety. Certified raw materials are verified to be BPA-free and FDA/LFGB compliant. Production testing includes tensile strength validation, Shore A hardness checks, slit uniformity inspections, and 100% leak-proof performance tests. High-temperature aging and durability trials confirm long-term reliability. All manufacturing follows ISO 9001 and IATF 16949 certified quality systems with full batch traceability, ensuring consistent results across large-volume production.

Why Choose Us:

- Specialized Expertise: Over 20 years in silicone valve engineering for global F&B packaging.

- Full OEM Flexibility: Customized slit designs, flow rates, and branding options.

- High Efficiency: Automated injection molding and die-cutting for consistent, scalable output.

- Certified Reliability: Backed by ISO 9001, IATF 16949, FDA, LFGB certifications.

Factory Show:

Our advanced facility integrates CNC machining, precision EDM, and wire-cutting for mold tooling accuracy. Equipped with 15 compression molding presses and 2 dedicated LSR injection molding units, we handle both prototyping and mass production efficiently. Automated doming, slit-cutting, and sealing performance testers ensure every valve meets stringent leak-proof standards. Supported by 3D measurement systems, elasticity gauges, and sealing pressure testers, we deliver high-volume production with unmatched consistency and reliability.