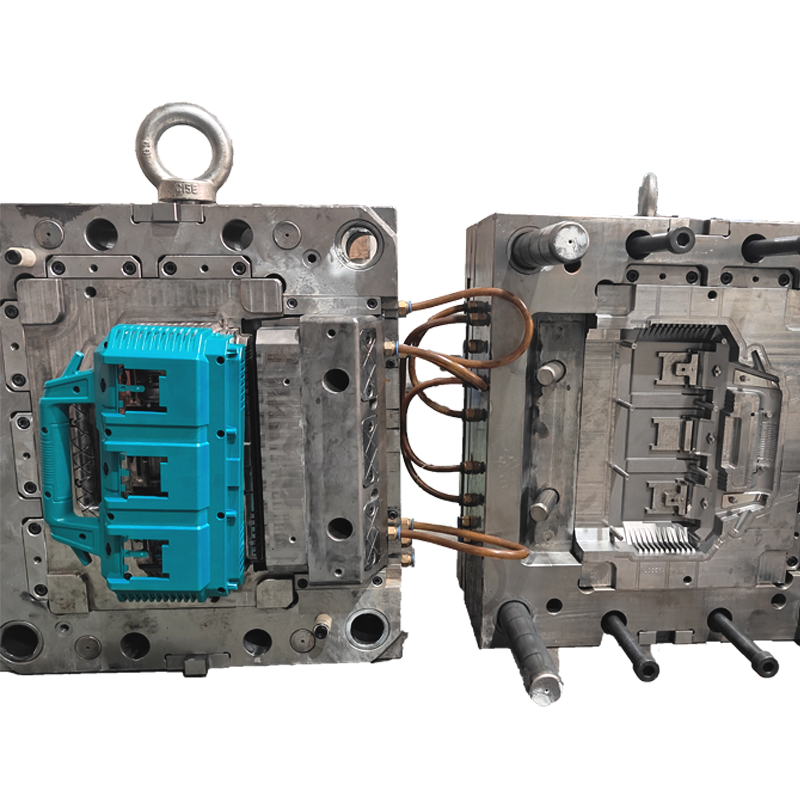

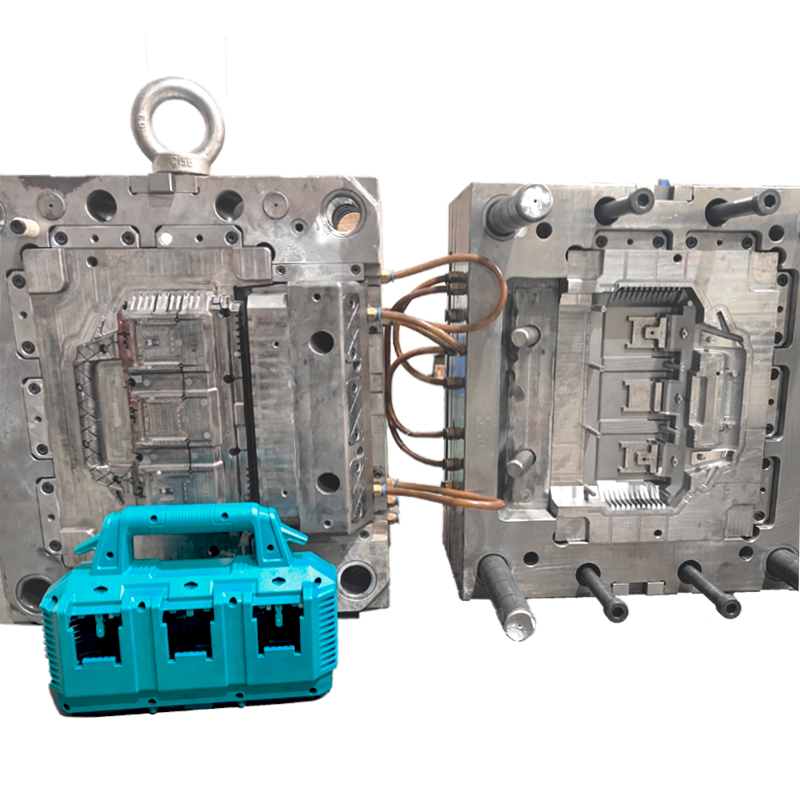

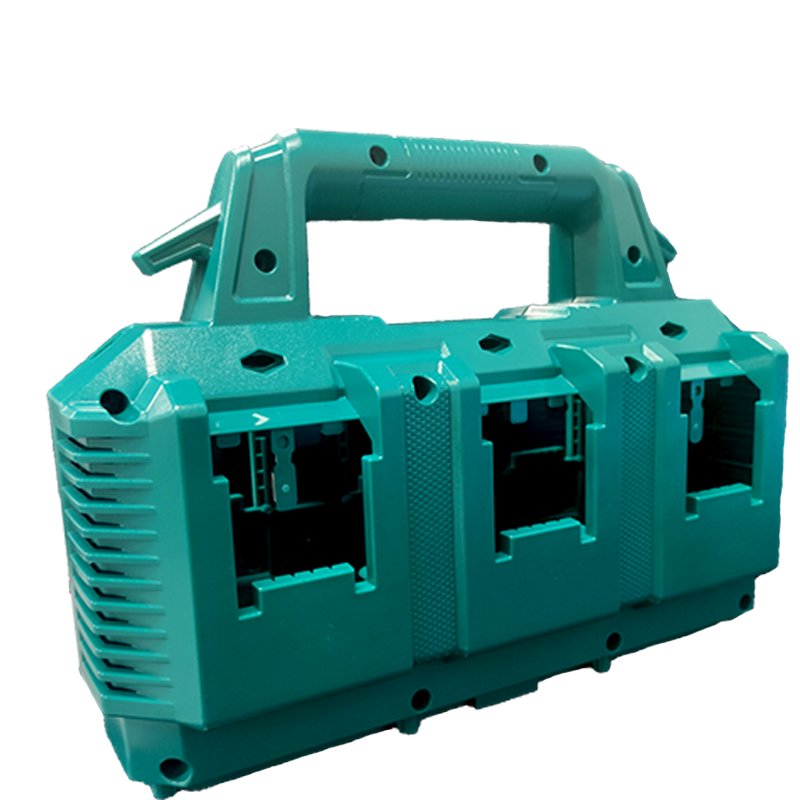

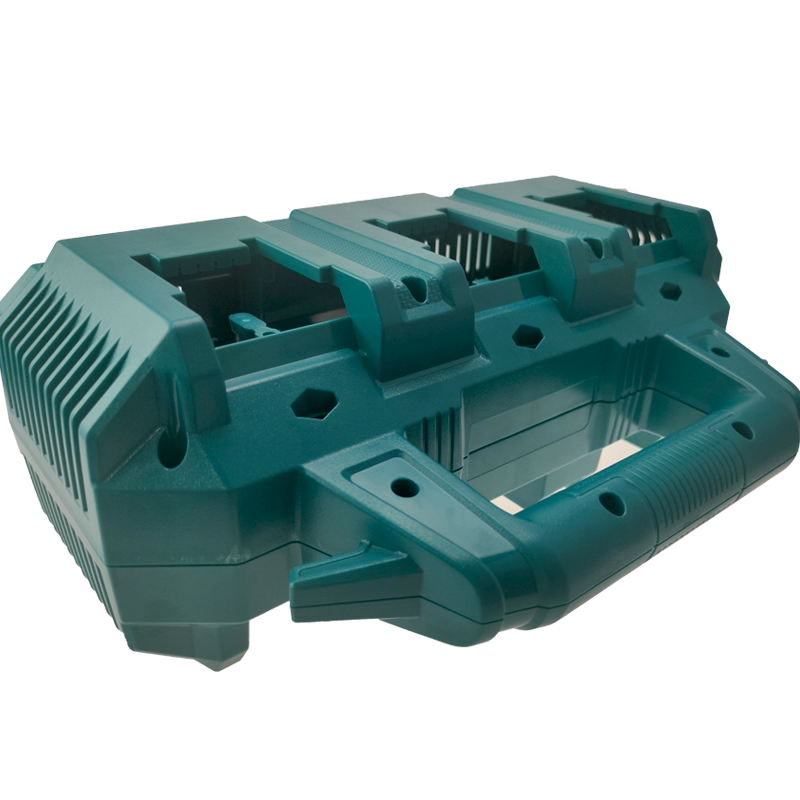

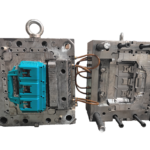

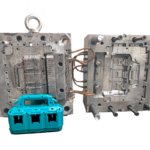

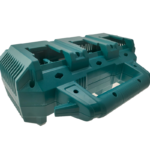

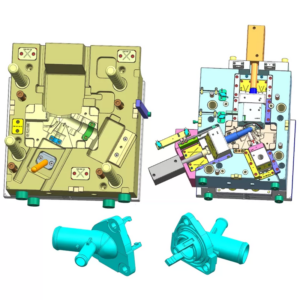

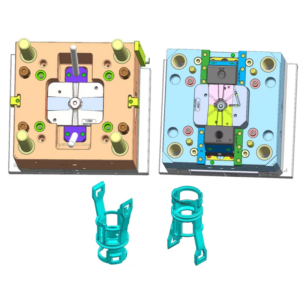

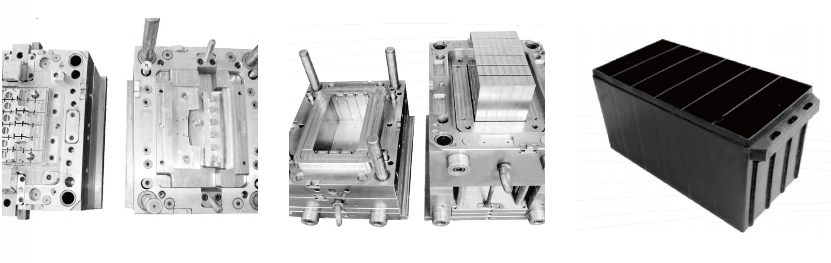

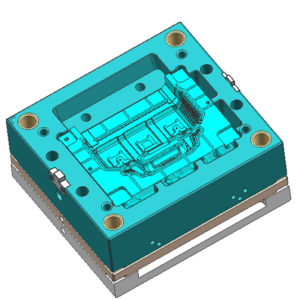

Herramientas para la Caja de Batería - Molde de Caja de Batería de Plástico

Los moldes de cajas de baterías de nuestra colección de primera línea ofrecen la solución ideal para satisfacer todas tus necesidades de fabricación de baterías. Disponibles teniendo en cuenta baterías de plomo-ácido, celdas de iones de litio y opciones de SAI, nuestros expertos en la fabricación de moldes para baterías comprenden la importancia de encontrar moldes adaptados específicamente a sus entornos de trabajo y requisitos.

Nuestra amplia colección de moldes para cajas de baterías incluye varias series adaptadas a diferentes tipos de baterías. Para baterías automotrices, ofrecemos moldes de las series N40, N50, N70, N100, N120, N150 y N200, proporcionando un ajuste perfecto para los requisitos específicos de su vehículo. Si necesita baterías para UPS, nuestros moldes de las series 55AH, 90AH y 100AH están diseñados para satisfacer de manera fiable sus necesidades de energía de respaldo. Para baterías de inversor, ofrecemos moldes de la serie IT 500, y para baterías DIN, tenemos las series DIN55 y DIN66. Además, somos capaces de crear moldes de cajas de baterías de plástico personalizadas según sus especificaciones únicas.

Como un nuevo fabricante de moldes para piezas de energía, contamos con muchos años de conocimiento y experiencia profesional, centrándonos en proporcionar soluciones de moldes excelentes para el campo de la nueva energía. Nuestras capacidades de diseño y fabricación de matrices están diseñadas para satisfacer las necesidades y especificaciones específicas de los clientes, asegurando que estos puedan obtener piezas de alta calidad.

Nuestro servicio incluye:

- Diseño de Moldes y Soporte de Ingeniería

- Selección de Materiales y Recomendaciones

- Fabricación de Moldes

- Desarrollo de Prototipos

- Prueba y Ajuste del Molde

- Entrega Rápida

- Aseguramiento de la Calidad

- Prácticas de Sostenibilidad

Capacidad:

- Diseño y Fabricación de Alta Precisión

- Reproducción Precisa de Geometrías Complejas

- Diseño de Múltiples Cavidades para una Mayor Eficiencia

- Materiales y Procesos de Fabricación Resistentes a Altas Temperaturas

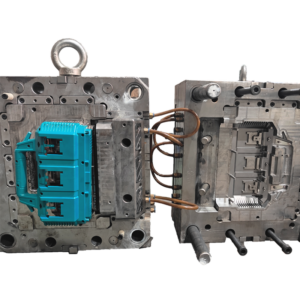

- Sistema de Refrigeración de Precisión

- Longevidad y Mantenimiento

- Sistema de Control de Calidad

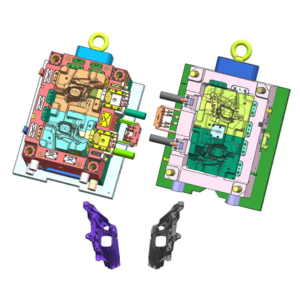

Tipos de herramientas

1. Herramientas de prototipado

El utillaje de prototipos, también conocido como utillaje blando o utillaje rápido, consiste en diseñar, producir y probar herramientas para verificar su ajuste, forma y función en preparación para el proceso de producción. Durante el proceso de prototipado, los fabricantes pueden ajustar el diseño varias veces para lograr un rendimiento y acabado óptimos. Algunos de los materiales que se utilizan con frecuencia en el prototipado son el caucho de silicona, la aleación de aluminio y el acero blando debido a su menor costo; suelen ser más rápidos y fáciles de moldear. Los beneficios del utillaje de prototipos incluyen:

- Crea prototipos rápidamente, a menudo tardando solo unas horas o días en lugar de varias semanas.

- Inversión menor, que permite realizar pruebas para verificar defectos de diseño, tolerancias y más.

- Se pueden producir piezas precisas.

2. Herramientas de producción

El utillaje de prototipos, también conocido como utillaje blando o utillaje rápido, consiste en diseñar, producir y probar herramientas para verificar su ajuste, forma y función en preparación para el proceso de producción. Durante el proceso de prototipado, los fabricantes pueden ajustar el diseño varias veces para lograr un rendimiento y acabado óptimos. Algunos de los materiales que se utilizan con frecuencia en el prototipado son el caucho de silicona, la aleación de aluminio y el acero blando debido a su menor costo; suelen ser más rápidos y fáciles de moldear. Los beneficios del utillaje de prototipos incluyen:

Proceso de Fabricación de Moldes

- Verificación de Producto 3D y DFM

- Diseño de herramientas y obtener aprobación.

- Compra de material para moldes

- Edificio destacado del proceso de CNC y EDM.

- Mecanizado auxiliar como EDM por hilo, perforación y rectificado.

- Pulido

- Montaje de moldes

- Control de Calidad

- Muestra T0 y P0 para aprobación del cliente.

- Empaque y entrega

Tolerancias ajustadas

Utilizando EDM por hilo, CNC de 5 ejes y otros equipos de alta precisión para lograr tolerancias de hasta 0.01 mm.

Máquinas principales de fabricación de utillaje

| Maquinaria | Cantidad |

| Alta velocidad de 42000 y CNC de precisión | 2 |

| Otras 7 máquinas CNC | 7 |

| EDM de hundimiento Makino | 4 |

| EDM de hilo Sodic | 5 |

| Molienda de Alta Precisión | 5 |

Materiales

- P20 (P20HH)

- S136 (S136H)

- NAK80

- H13

- 718 (718H)

- 2738 (P20+Ni)

- 2316

- MoldMAX

- Aluminio

¿Por qué elegirnos para la fabricación de herramientas?

1. Equipos y tecnología avanzada

Poseemos equipos y tecnología de fabricación avanzados, incluyendo máquinas CNC de alta precisión, software CAD/CAM y tecnología de impresión 3D. Estas herramientas avanzadas nos permiten lograr una fabricación precisa de utillajes y conseguir detalles intrincados y formas complejas con la máxima exactitud.

2. Diseño personalizado y soporte de ingeniería

Trabajamos en estrecha colaboración con nuestros clientes, adquiriendo una comprensión profunda de sus necesidades y requisitos del producto. Nuestro experimentado equipo de ingenieros ofrece asesoramiento profesional en diseño y soporte técnico, asegurando que el diseño de las herramientas cumpla con las expectativas del cliente y los requisitos específicos del producto.

Materiales y estándares de fabricación de alta calidad

Seleccionamos estrictamente materiales de alta calidad para nuestras herramientas, como acero de primera calidad y aleaciones resistentes al desgaste. Además, nos adherimos a estrictos estándares y procesos de control de calidad para garantizar la calidad de fabricación y la consistencia de cada herramienta. Esto contribuye a mejorar la durabilidad, estabilidad y vida útil de la herramienta.

4. Innovación Tecnológica y Mejora Continua

Como una fábrica impulsada por la innovación y en constante mejora, perseguimos constantemente la innovación tecnológica, explorando nuevos métodos y materiales de fabricación. Al incorporar procesos y tecnologías avanzadas, mejoramos la precisión, complejidad y eficiencia de producción de nuestras herramientas para satisfacer las demandas del mercado en constante evolución.