At The term "YJCPolymer" seems to be a name or brand and does not require translation. It would remain the same in Spanish. If you need assistance with a specific context or additional content, please provide more details! we know your product’s reputation depends on repeatable quality. That’s why we’ve embedded automated quality checks across our injection molding lines. If you’re an OEM, product designer, or sourcing manager searching for a manufacturing partner who delivers high-quality parts consistently, this article explains exactly how our factory turns data, vision systems, and tight process control into reliable outcomes you can trust.

Why automation matters now

The modern market demands smaller tolerances, faster throughput, and complete traceability. Manual inspection can no longer be the backbone of a robust quality program. Human inspection is subjective, inconsistent, and slow. Automated quality systems remove variability, catch defects in real time, and create an audit trail that satisfies regulatory and OEM requirements. At YJCPolymer, automation is part of our one-stop service offering: mold design validation, production, inline QC, and supplier management bundled to minimize risk for our customers.

What are automated quality checks?

Automated quality checks are a set of hardware and software tools that inspect parts during production without stopping the line. Typical elements include:

- In-process sensors embedded in the mold or machine to monitor temperature, pressure, screw position, and shot weight.

- Machine vision systems using 2D cameras and 3D laser/structured-light scanners for surface inspection, geometry checks, and color verification.

- Automated metrology such as inline coordinate measuring systems and laser micrometers to verify critical dimensions.

- Process analytics and MES integration to capture cycle data, apply statistical process control, and generate traceable QA records.

- AI and pattern recognition that learn defect signatures and reduce false positives.

Together these technologies flag deviations immediately, so operators can act before a full run is scrapped.

How YJCPolymer implements automated QC — a layered approach

We design quality into the process with layered, redundant controls that catch problems early and provide prescriptive responses.

- Process-level control

Every press is instrumented with pressure and temperature sensors. We define an optimal “process window” for each tool and part. If a curve drifts outside limits the system alerts operators and can automatically pause the press to prevent bad shots. - In-mold and cavity monitoring

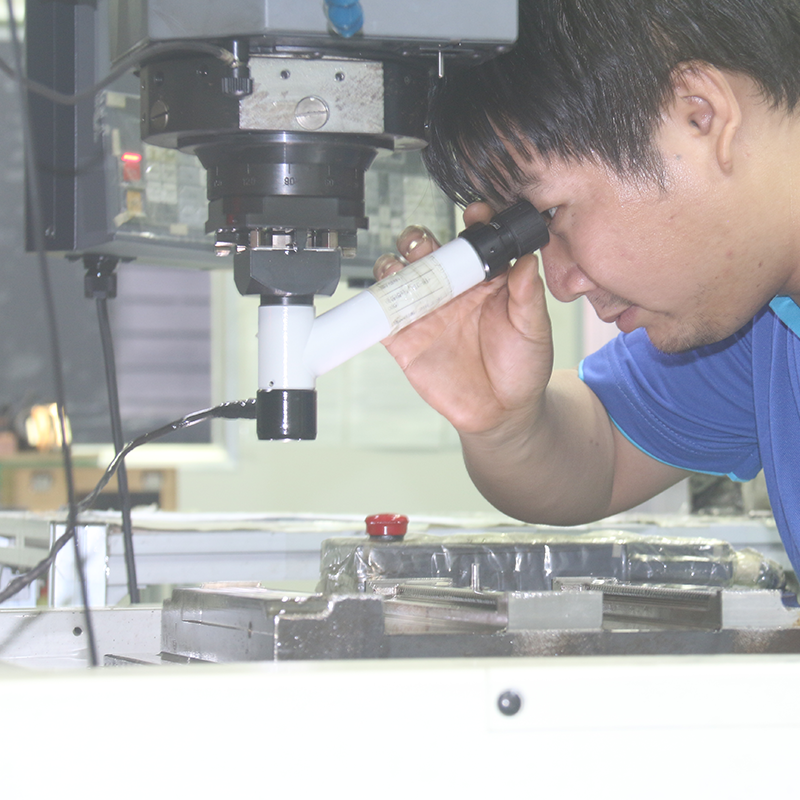

For critical components we install cavity pressure sensors and hot-runner thermocouples. Cavity signatures let us verify proper fill and packing without destructively testing parts. - Vision and surface inspection

High-resolution cameras check for flash, short shots, weld lines, sink marks, discoloration, and foreign material. 3D laser scanning verifies form and critical geometry to micrometer-level tolerances. - Automated dimensional metrology

Inline CMM cells and laser micrometers measure holes, wall thickness, bosses, and snap-fit dimensions. Data is compared to CAD nominal values and out-of-tolerance parts are automatically diverted. - Data collection and analytics

All process and inspection data feed our MES. Statistical process control charts, control limits, and trend analytics detect drift and predict maintenance needs. - Traceability and reporting

Each part or batch receives a digital passport tying cycle data, material lot numbers from suppliers, tool IDs, and inspection results for full traceability and simplified audits for OEM customers.

Business benefits for OEMs and suppliers

Automated checks deliver measurable advantages for brands and suppliers:

- Consistent high quality that reduces field failures and warranty claims.

- Lower scrap and rework costs because defects are caught immediately.

- Faster time-to-market because fewer manual inspections mean shorter cycle times and reliable ramp-up.

- Regulatory compliance and documentation for medical, automotive, and aerospace customers.

- Supplier transparency — material lots, certificates, and in-line results are linked so your procurement team can verify supplier performance.

Real-world ROI

For many projects the payback on automated inspection is straightforward. Reduced scrap, fewer line stoppages, and decreased labor for manual inspection typically offset capital outlay within months to a couple of years depending on volume and defect risk. For mission-critical OEM parts the intangible benefits — brand protection and regulatory confidence — are often the deciding factor.

Implementation best practices from the factory floor

If you plan to adopt automated checks, consider these practical recommendations from our engineers:

- Design for inspection — place critical features where vision and probes can access them, and ensure consistent fixturing.

- Specify control limits early — define acceptable tolerances during DFM and tool tryout, not after production starts.

- Start with critical-to-function features and expand inspection as ROI and confidence grow.

- Integrate QC with MES/ERP to automate traceability and supplier feedback loops.

- Use pilot runs to collect baseline data for AI models and SPC control limits prior to full production.

- Train staff to interpret analytics and follow rapid corrective actions.

Challenges and how we solve them

Automation is powerful but not a silver bullet. Common challenges include lighting variability for vision, fixturing repeatability, and integrating disparate data sources. YJCPolymer addresses these by standardizing lighting and fixturing across lines, using robust edge computing for pre-processing images, and applying middleware to unify data across equipment vendors. We also work closely with material suppliers to qualify resin batches and reduce variation originating upstream.

Quality culture — technology plus people

Even the most advanced systems require skilled technicians and quality engineers to tune parameters and interpret insights. Our factory invests in ongoing training, cross-functional problem solving, and continuous improvement programs so automated checks are an extension of a strong quality culture, not a replacement for it.

Industries and applications that benefit most

Automated quality inspection is especially valuable for:

- Automotive where connectors, housings, and safety-related parts need tight tolerances and traceability.

- Medical where devices and components must meet ISO and FDA documentation requirements.

- Electronics where tiny features and cosmetic appearance are mission-critical.

- Consumer goods and packaging where consistent visual quality drives brand perception.

Partnering with YJCPolymer

As an experienced OEM manufacturer, YJCPolymer provides a one-stop service that includes design-for-manufacture review, mold tryout with automated checks, production scaling, and supplier coordination. We collaborate with upstream suppliers to manage resin lots, colorants, and additives so the material variability is kept within process capability.

If you’re evaluating manufacturing partners, ask about their automated inspection strategy, data retention policies, and how inspection data is linked to material certificates and tooling records. At YJCPolymer we make those answers straightforward and auditable.

Final thoughts and invitation

Quality isn’t an afterthought. At YJCPolymer we design it into every shot, every cycle, and every shipment. If your project requires consistent high quality, strong traceability, and the benefits of OEM-level manufacturing, let’s talk. Share your drawings or requirements and we’ll outline a tailored automated QC plan and production roadmap that balances cost, speed, and reliability.

Contact YJCPolymer today for a consultation. We’ll show how our factory, supplier network, and automated inspection capabilities can deliver the dependable parts your brand needs.