Resumen

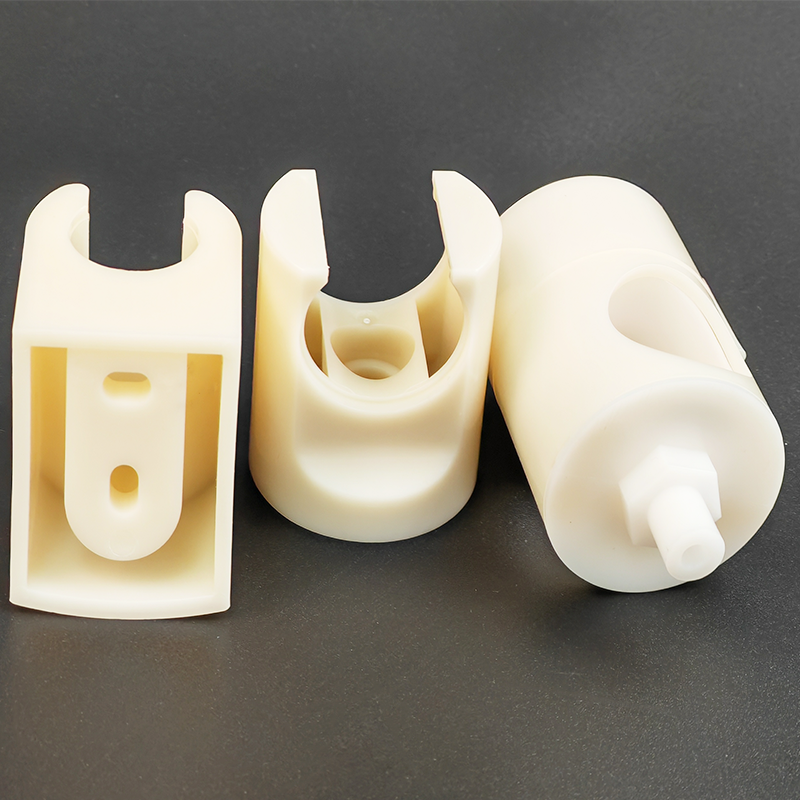

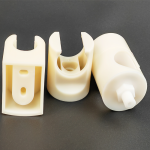

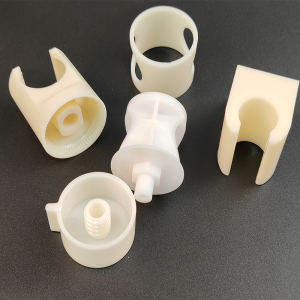

Nuestro soporte de ducha de pared ajustable en TPE es una solución de montaje duradera y elegantemente diseñada para duchas de mano que combina superficies de agarre en TPE de tacto suave con una base de montaje rígida de polímero o metal. Diseñado para un ajuste de ángulo suave, un bloqueo seguro y resistencia a la corrosión en entornos húmedos, el soporte es ideal para aplicaciones en baños residenciales, de hostelería y comerciales. Ofrecemos servicios completos de OEM: selección de materiales, sobremoldeo, igualación de colores, empaquetado de marca privada y validación de rendimiento, para que obtengas un componente listo para el mercado que equilibre estética, ergonomía y una larga vida útil.

Información Básica

| Atributo | Detalles |

|---|---|

| Nombre del producto | Soporte de ducha de pared ajustable para cabezal de ducha de mano (TPE) |

| Lugar de Origen | Xiamen, China |

| Nombre de la marca | OEM / Marca blanca |

| Material | Sobremoldeo de elastómero termoplástico (TPE) sobre inserto de ABS/PC o acero inoxidable (personalizable) |

| Dureza | TPE Shore A 50–70 (personalizable) |

| Terminar | Exterior de TPE mate y suave al tacto; base de ABS brillante/mate o metal chapado. |

| Tipo de Montaje | Tornillo de fijación (anclajes de pared), almohadilla adhesiva o soporte oculto (opciones) |

| Rango de Ajuste | Inclinación ±45° (típ.); opción de giro de 360° disponible. |

| Capacidad de carga | Carga de trabajo típica de 5 a 10 kg (dependiendo del diseño) |

| Rango de Temperatura | −40 °C a +110 °C (dependiendo del TPE) |

| Tolerancia | ±0.10 mm (estándar); tolerancias más ajustadas a petición. |

| Tiempo de entrega de muestra | 5 a 7 días hábiles |

| Tiempo de producción | 15 a 30 días hábiles (dependiendo de las herramientas) |

| Cantidad Mínima de Pedido | Flexible — se aceptan pequeñas producciones piloto. |

| Envase | Granel / tarjeta de blíster / caja de color para venta al por menor / embalaje personalizado |

| Certificaciones | ISO 9001; RoHS; REACH (declaraciones de materiales disponibles) |

| La tecnología de fabricación | Inyección de plásticos, moldeo por inyección de dos componentes / sobreinyección, mecanizado CNC, soldadura ultrasónica. |

Beneficios clave

- Agarre suave y seguro: Las superficies de contacto sobre moldeadas en TPE evitan el deslizamiento y reducen el desgaste en las duchas, al mismo tiempo que ofrecen una sensación premium y suave al tacto.

- Corrosión y Resistencia al Agua: El uso de polímeros diseñados y de insertos de acero inoxidable opcionales garantiza una larga vida útil en entornos húmedos y clorados.

- Ajuste suave y repetible: La geometría de pivote de precisión con enclavamiento positivo o bloqueo por fricción ofrece un control de ángulo consistente y previene el desplazamiento.

- Flexibilidad Estética: Coherencia total en la correspondencia de colores Pantone para TPE y materiales base, además de texturas personalizadas o niveles de brillo para que coincidan con los accesorios de baño modernos.

- Múltiples opciones de montaje: tornillo, adhesivo de alta resistencia o sistemas de montaje ocultos que se adaptan a instalaciones en azulejos, paneles de yeso y paneles.

- Listo para OEM: Las opciones de personalización incluyen impresión en almohadilla, grabado láser, logotipos en relieve y empaques minoristas personalizados para ventas directas en estantería o de marca privada.

Especificaciones Típicas

- Compuesto TPE: elastómero termoplástico de grado con resistencia a los UV y al cloro (formulado para flexibilidad a largo plazo).

- Base substrate: ABS-PC blend (UL94 HB) or glass-filled nylon for higher strength; optional 304/316 stainless steel insert for screw anchoring.

- Sobreinyección: Inyección de dos componentes o sobreinyección posterior con flash controlado ≤ 0,2 mm.

- Fricción/Bloqueo: Resorte de torsión ajustable o buje de nylon para un par de inclinación controlado.

- Surface treatments: matte soft-touch, micro-texturing, or TPU coating for specialty finishes.

- Fasteners: stainless steel screws and brass wall anchors included on request.

Aseguramiento de la Calidad

Aplicamos un protocolo de aseguramiento de calidad (QA) integral para garantizar el rendimiento y la durabilidad en entornos húmedos. Los materiales entrantes de TPE y sustrato se prueban por lotes para evaluar la dureza, la resistencia a la tracción y la resistencia química. Las piezas moldeadas se someten a inspección dimensional con máquinas de medición por coordenadas (CMM) y perfiles ópticos, mientras que los conjuntos de pivote se someten a pruebas de ciclo de vida (normalmente >50,000 ciclos) para evaluar la estabilidad del par y la retención. Se realizan pruebas de resistencia a la corrosión y de rocío salino para insertos metálicos y fijaciones. Todos los lotes de producción incluyen inspecciones visuales, funcionales y de embalaje, con trazabilidad completa de lotes y declaraciones de materiales (RoHS/REACH) proporcionadas.

¿Por qué asociarse con nosotros?

- Servicio OEM Llave en Mano — Desde DFM y selección de materiales hasta herramientas, moldeo, ensamblaje y embalaje para venta al por menor.

- Personalización flexible: color, dureza, método de montaje, logo y embalaje adaptados a tu marca.

- Diseño Robusto para Entornos Húmedos — Materiales y recubrimientos elegidos específicamente para baños, spas y aplicaciones hoteleras.

- Controles de Fabricación Probados — Procesos liderados por ISO, pruebas de ciclo de vida y documentación para apoyar lanzamientos de productos y auditorías de adquisiciones.

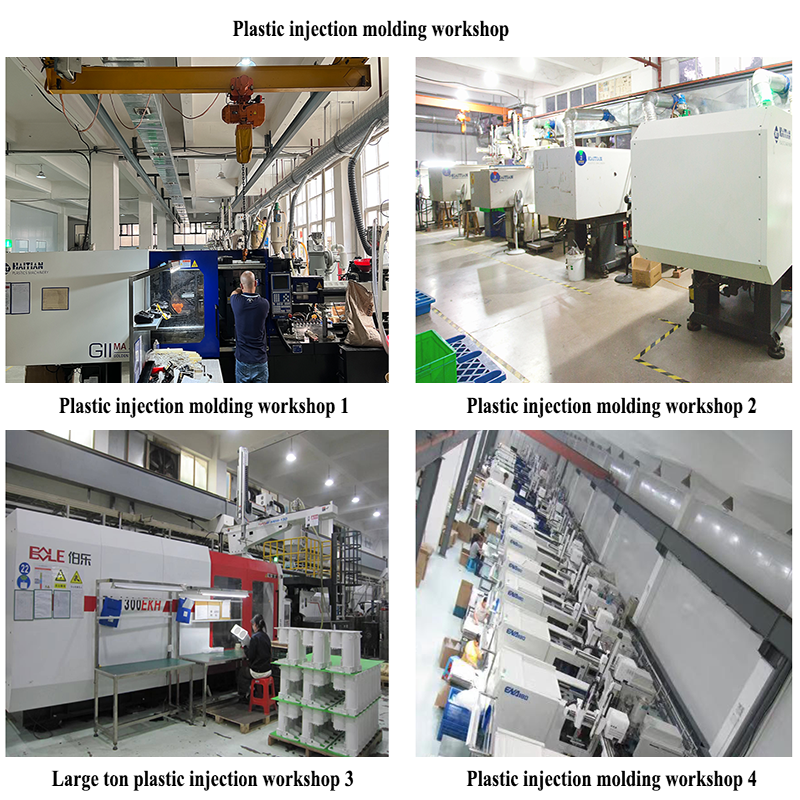

Capacidades de la Fábrica

Nuestras capacidades de herramientas y producción incluyen la fabricación de moldes CNC de alta precisión, EDM de espejo y WEDM para geometrías de cavidad ajustadas, además de prensas de inyección de múltiples inyecciones y líneas de sobreinyección configuradas para combinaciones de TPE/sustratos rígidos. Las estaciones de ensamblaje realizan soldadura ultrasónica, colocación de insertos (insertos metálicos) y kits de tornillos/anclajes. Operamos laboratorios de control de calidad dedicados para pruebas de actuación del ciclo de vida, evaluación de spray de sal/corrosión, validación dimensional y trazabilidad de lotes bajo controles ISO 9001.