Hello, medical device innovators and product development teams! Have you ever stopped to consider the tiny, critical window on your pulse oximeter? It seems simple, right? Just a piece of plastic. But in reality, that lens cover is the guardian of accuracy, the interface between your sensitive internal optics and the unpredictable outside world. Getting it wrong means unreliable readings, device failure, and lost user trust. So, how do you ensure this small part delivers monumental performance, especially when scaling for global demand? Here at YJCPolymer, we specialize in turning this critical component into a competitive advantage for your brand through the precision of custom two-shot molding with PC and Acrylic.

This isn’t just about molding plastic; it’s about fusing two distinct materials into a single, flawless component that meets the rigorous demands of the medical field. Let’s pull back the curtain on the sophisticated engineering and one-stop service that goes into manufacturing a two-shot oximeter lens cover, from initial design to mass production.

Why the Material Marriage of PC and Acrylic is a Game-Changer

Choosing the right materials is the first step to achieving high quality. For oximeter lenses, a combination of Polycarbonate (PC) and Acrylic (PMMA) offers an unparalleled synergy.

-

Polycarbonate (PC) as the Frame: The first shot, typically the outer frame or housing, is made from PC. Why? PC is incredibly tough, impact-resistant, and provides excellent structural integrity. It can withstand drops, assembly stresses, and the general rigors of daily use, protecting the delicate electronics housed within the oximeter.

-

Acrylic (PMMA) as the Lens: The second shot is Acrylic. This is the critical choice for the optical lens itself. Acrylic offers superior light transmission properties compared to PC. It is exceptionally clear, resistant to yellowing over time, and can be easily polished to an optically perfect finish. This clarity is non-negotiable for allowing the red and infrared light from the LEDs to pass through the skin and back to the sensor with minimal distortion, which is the very principle of pulse oximetry.

By combining them, you get the best of both worlds: the rugged, protective strength of PC and the crystal-clear, optically pure performance of Acrylic.

The Two-Shot Molding Process: A Ballet of Precision

This is where the magic happens. Two-shot molding isn’t two separate processes glued together; it’s a single, integrated, and automated cycle within a specialized injection molding machine. At YJCPolymer, our process is a meticulous dance of precision engineering.

Stage 1: The First Shot – Creating the PC Skeleton

The process begins with a custom-machined, multi-cavity mold installed in a two-shot injection molding press. The first mold cavity is in the shape of the PC frame.

-

Material Preparation: Medical-grade Polycarbonate resin is carefully dried to remove any moisture, which can cause defects. It is then fed into the injection unit.

-

Injection and Cooling: The molten PC is injected under high pressure into the first cavity, forming the robust frame of the lens cover. The mold cools, and the PC solidifies.

Stage 2: The Mold Shift – The Core Technical Maneuver

This is the key differentiator. Instead of ejecting the PC frame, the mold core—which holds the newly formed PC parts—rotates 180 degrees (or shifts laterally) to position the PC frame precisely into the second mold cavity. This second cavity is shaped to form the Acrylic lens in perfect alignment with the PC frame.

Stage 3: The Second Shot – Encapsulating with Optical-Grade Acrylic

With the PC frame now locked into the second cavity:

-

Second Injection Unit: The machine’s second injection unit, filled with meticulously prepared medical-grade Acrylic, swings into action.

-

Bonding and Forming: The molten Acrylic is injected directly onto and against the PC frame. The heat and pressure create a permanent, molecular-level bond between the two materials at the interface. This bond forms the seamless seal and creates the optical lens in a single, fluid motion.

Stage 4: Ejection and Inspection

The mold opens, and a single, completed part—a PC frame with a perfectly integrated Acrylic lens—is ejected. There are no glue lines, no misalignment, and no risk of delamination. Each part undergoes immediate automated optical inspection for clarity, dimensional accuracy, and any potential flaws.

The Unbeatable Advantages for Your Oximeter

Why go through this complex process? The benefits for your product and brand are substantial:

-

A Perfect, Hermetic Seal: The molecular bond created during the two-shot process eliminates the need for secondary adhesives or ultrasonic welding. This creates a completely sealed barrier against dust, moisture, body fluids, and cleaning agents. This ingress protection (IP rating) is critical for device sterilization and long-term reliability.

-

Unmatched Optical Performance: With no glue or welding lines to disrupt the light path, the Acrylic lens provides a perfectly clear window. This ensures the highest signal integrity for the sensor, leading to more accurate and consistent SpO2 and heart rate readings.

-

Dramatically Enhanced Durability: The monolithic nature of the part means it can withstand significant stress without the lens popping out or the seal breaking—a common failure point in traditionally assembled lens covers.

-

Streamlined Assembly and Cost-Effectiveness in Mass Production: Since the part comes out of the mold ready to use, you eliminate multiple assembly steps: no separate lens, no adhesive application, no curing time, and no alignment jigs. This reduction in part count and labor translates to lower overall assembly costs and a faster production line, which is a decisive advantage when scaling for mass production.

YJCPolymer: Your Partner in Precision Medical Manufacturing

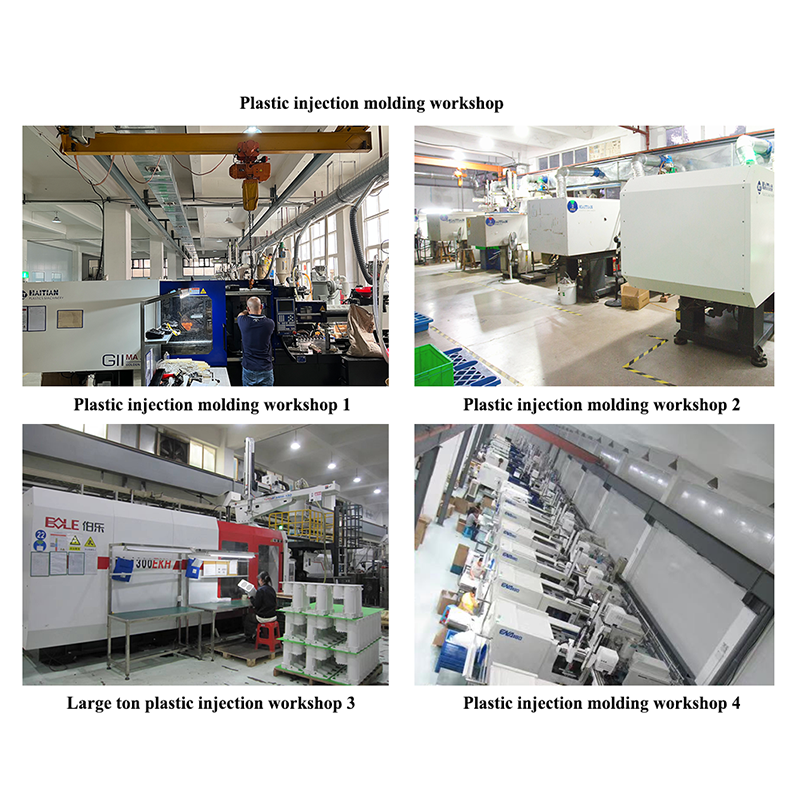

As expert OEM service providers in the medical polymer space, we understand that your reputation is on the line with every component. Our one-stop service model means we are with you from the initial Design for Manufacturability (DFM) analysis, where we help optimize your part for the two-shot process, all the way through to high-volume mass production and rigorous quality assurance. We invest in the advanced machinery and clean-room environments necessary to produce medical-grade components that consistently meet high quality standards.

So, as you refine your next-generation medical monitoring devices, remember that the smallest components often carry the biggest responsibility. Is your current lens design living up to its full potential? Could a seamlessly bonded PC and Acrylic solution enhance your product’s accuracy, durability, and user trust? Let’s talk. Contact the YJCPolymer team today to discuss your project—we’re ready to bring clarity and precision to your most vital components.